Coal pile surface waterproof covering agent and preparation method thereof

A covering agent, water-based technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of unsuitable open-pit coal pile dust suppression, low-level calorific value drop, low bonding strength, etc., to prevent coal loss and environmental protection. The effect of pollution, low temperature, and simple operation of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

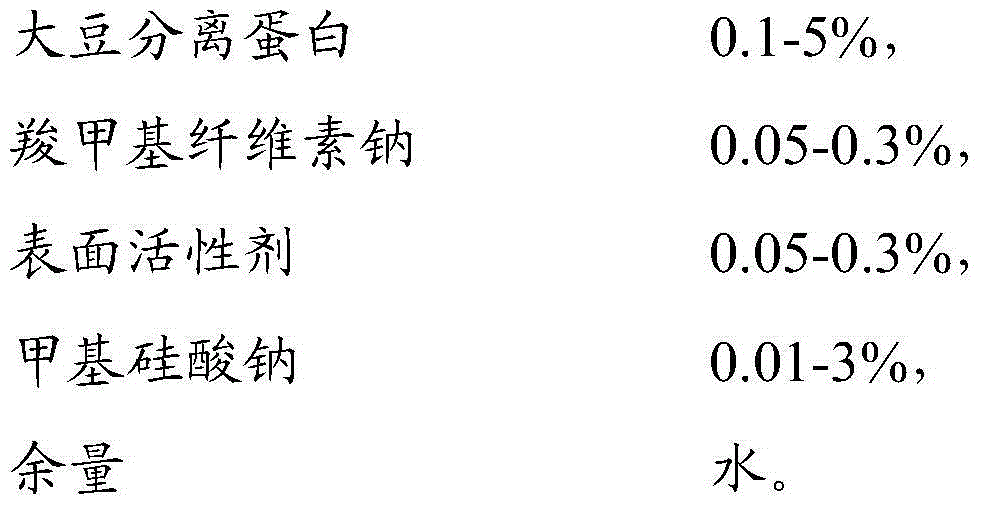

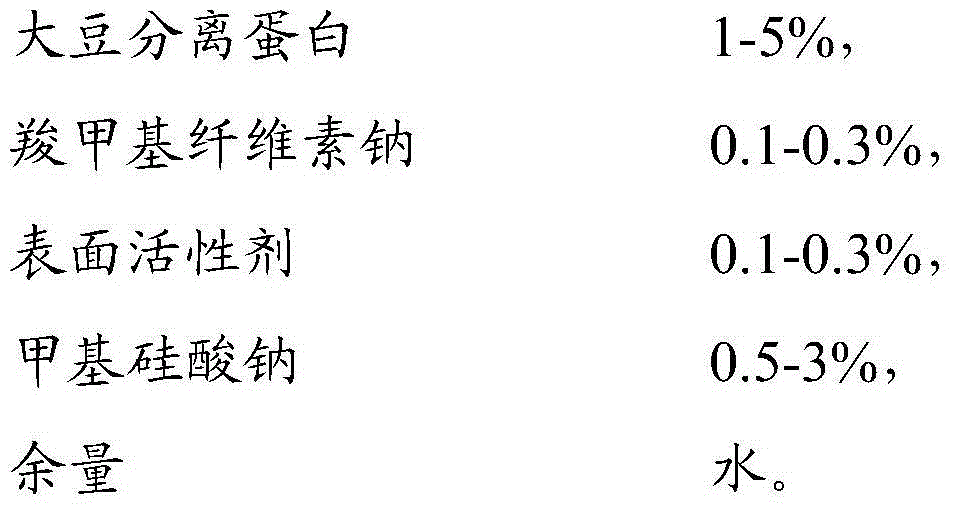

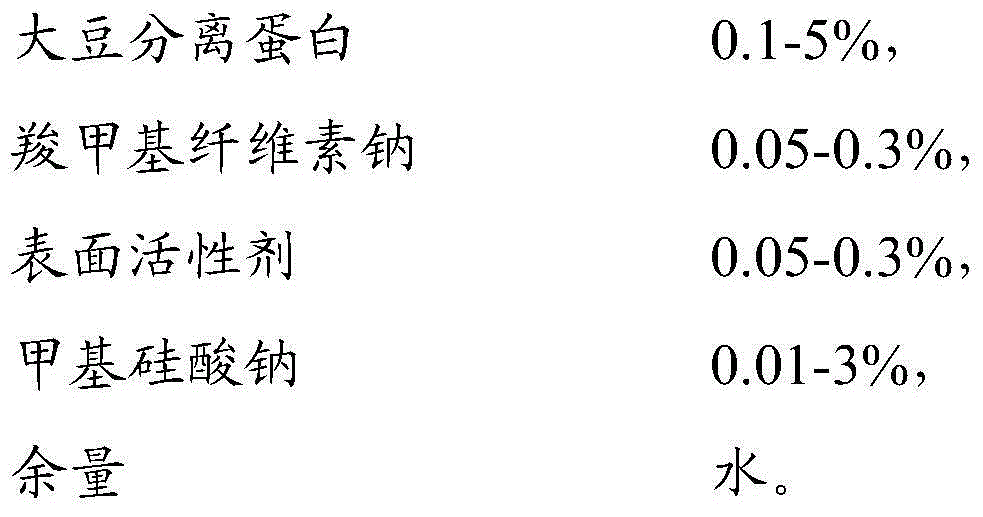

[0036] In this embodiment, a water-repellent covering agent for the surface of coal piles is prepared from raw materials with the following weights:

[0037] Soy protein isolate: 1g,

[0038] Sodium carboxymethylcellulose (molecular weight: 800-1200): 0.1g,

[0039] Sodium dodecylsulfonate: 0.1g,

[0040] 30% aqueous solution of sodium methyl silicate: 1.67g, containing sodium methyl silicate: 0.5g,

[0041] Water: Make up to 100g.

[0042] The preparation method of the above-mentioned coal heap surface water-repellent covering agent comprises the following steps:

[0043] (1) Add 1g soybean protein isolate, 0.1g sodium carboxymethylcellulose, 0.1g sodium dodecylsulfonate and 70g water into the reaction kettle, stir and heat to 60°C, react for 0.5h to obtain a mixed solution;

[0044] (2) After the mixture is completely cooled, add 1.67g of 30% sodium methyl silicate aqueous solution (3010 type sodium methyl silicate), and add water to make up the solution to 100g, and sti...

Embodiment 2

[0051] In this embodiment, a water-repellent covering agent for the surface of coal piles is prepared from raw materials with the following weights:

[0052] Soy protein isolate: 1g,

[0053] Sodium carboxymethylcellulose (molecular weight: 800-1200): 0.2g,

[0054] Sodium dodecylbenzenesulfonate: 0.2g,

[0055] 30% sodium methyl silicate: 1.67g, containing sodium methyl silicate: 0.5g,

[0056] Water: Make up to 100g.

[0057] The preparation method of the above-mentioned coal heap surface water-repellent covering agent comprises the following steps:

[0058] (1) Add 1g soybean protein isolate, 0.2g sodium carboxymethyl cellulose, 0.2g sodium dodecylbenzenesulfonate and 70g water into the reaction kettle, stir and heat to 60°C, and react for half an hour to obtain a mixed solution;

[0059] (2) After cooling the mixed solution completely, add 1.67g of 30% sodium methyl silicate aqueous solution (model 3010 sodium methyl silicate), and add water to replenish the solution t...

Embodiment 3

[0065] In this embodiment, a water-repellent covering agent for the surface of coal piles is prepared from raw materials with the following weights:

[0066] Soy protein isolate: 0.1g,

[0067] Sodium carboxymethylcellulose (molecular weight: 800-1200): 0.1g,

[0068] Sodium dodecylsulfonate: 0.1g,

[0069] 30% sodium methyl silicate: 1.67g, containing sodium methyl silicate: 0.5g,

[0070] Water: Make up to 100g.

[0071] The preparation method of the above-mentioned coal heap surface water-repellent covering agent comprises the following steps:

[0072] (1) Add 0.1g soybean protein isolate, 0.1g sodium carboxymethylcellulose, 0.1g sodium dodecylsulfonate and 70g water into the reaction kettle, stir and heat to 60°C, and react for half an hour to obtain a mixed solution;

[0073] (2) After the mixture is completely cooled, add 1.67g of 30% sodium methyl silicate aqueous solution (3010 type sodium methyl silicate), and add water to make up the solution to 100g, and stir we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com