Straight-going material taking method and device of bucket-wheel stacker-reclaimer

A bucket-wheel stacker-reclaimer and straight-line technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of small reclaiming flow rate, unable to meet the flow rate demand, and smaller reclaiming flow rate, and achieve Guarantee the material flow rate, enrich the unattended operation mode, and improve the effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to enable those skilled in the art to better understand the technical solution of the present disclosure, the present disclosure will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

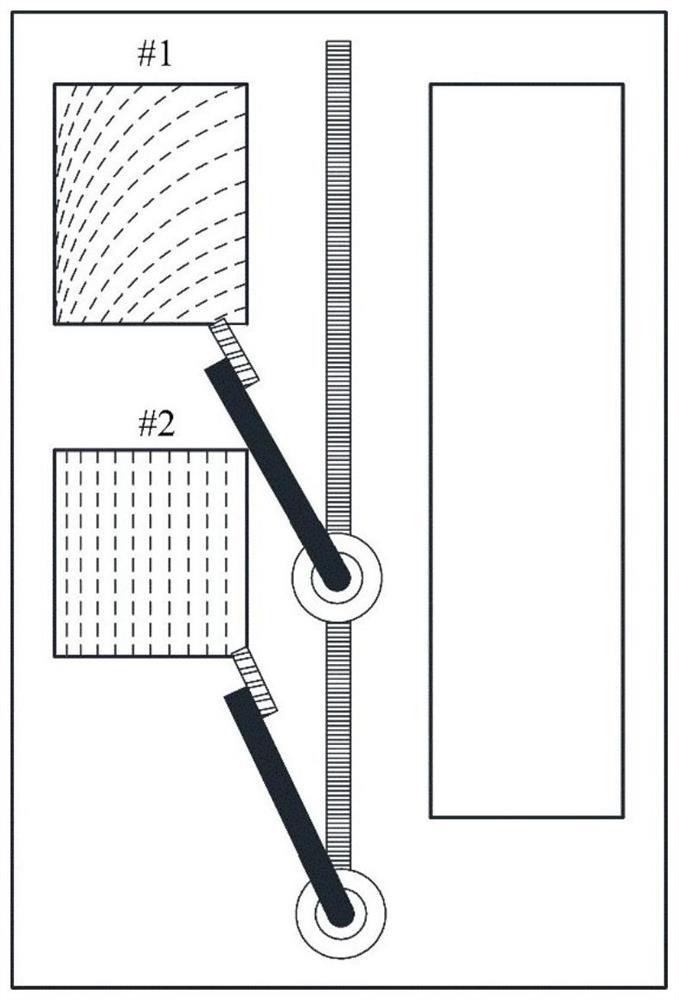

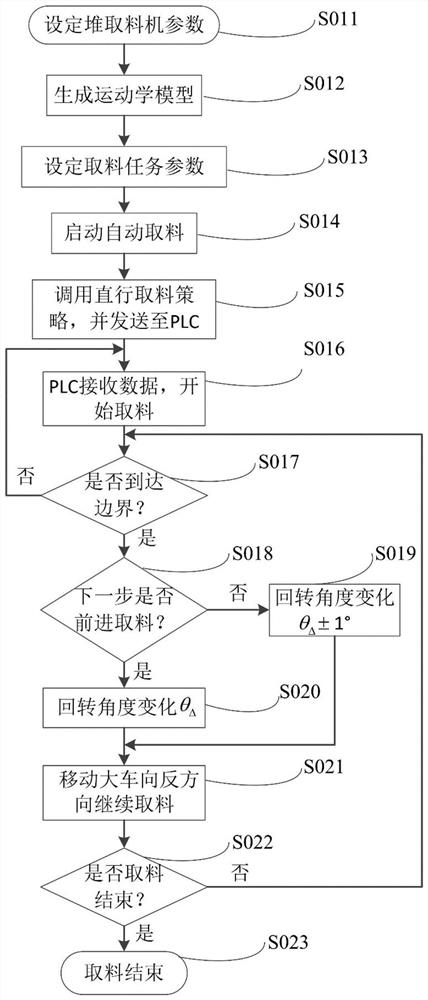

[0054] In one aspect of this embodiment, as figure 2 and image 3 Shown, relate to a kind of straight line reclaiming method of bucket wheel stacker reclaimer, described method comprises:

[0055] S011. Obtain the equipment mechanical parameters and basic operating data of the bucket-wheel stacker-reclaimer, as shown in Table 1 below:

[0056] Table 1

[0057]

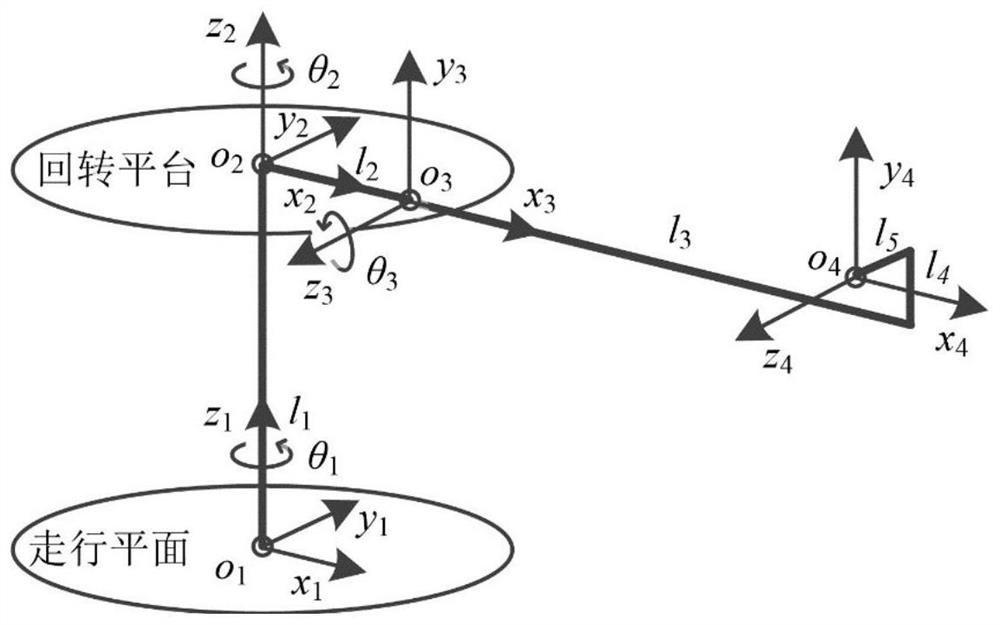

[0058] S012. According to the mechanical parameters of the equipment and the basic operating data, establish a kinematics model of the bucket wheel stacker-reclaimer based on robot kinematics theory; the kinematics model is used to characterize the bucket-wheel stacker-reclaimer The relationship between angle and position.

[0059] Specifically, in this s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com