Coal inventory system and method based on vision

A coal-panning and visual technology, applied in the field of vision-based coal-panting systems, can solve problems such as coal pile information fusion difficulties, coal quality loss, and coal reserve calculation difficulties, and achieve the effect of expanding application scenarios and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

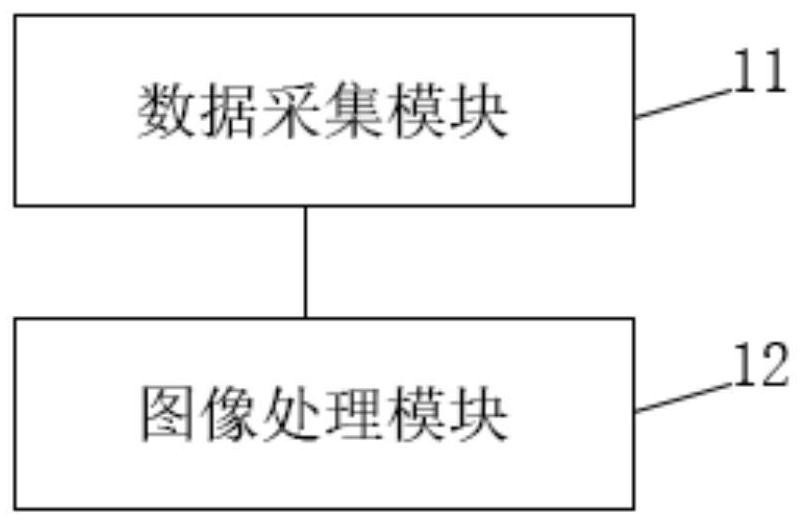

[0057] This embodiment provides a vision-based coal panning system, such as figure 1 As shown, it includes a data acquisition module and an image processing module, and the data acquisition module is connected with the image processing module;

[0058] The data collection module 11 is used to receive the image information of the coal storage yard acquired by the drone and the POS data information of the drone, and send the image information and the POS data information of the drone to the image processing module;

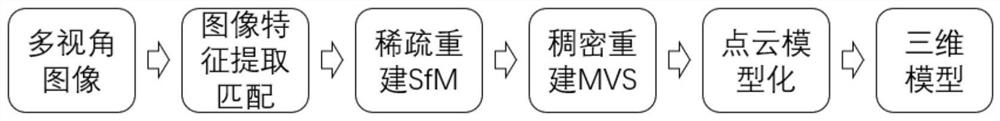

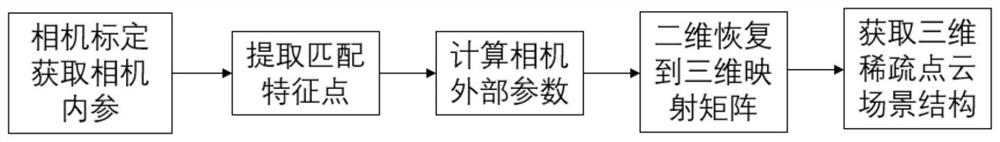

[0059] The image processing module 12 is used to calculate the parameters of the camera based on the motion recovery structure algorithm according to the image information and the POS data information of the drone, and construct a three-dimensional sparse point cloud model according to the parameters, and perform a dense point cloud according to the three-dimensional sparse point cloud model. The model is reconstructed, and the 3D model of the coal field is construc...

Embodiment 2

[0095] This embodiment provides a vision-based method for panning coal, such as Figure 7 shown, including steps:

[0096] S11. Receive the image information of the coal storage yard acquired by the drone and the POS data information of the drone, and send the image information and the POS data information of the drone to the image processing module;

[0097] S12. Calculate the parameters of the camera based on the motion recovery structure algorithm based on the image information and the POS data information of the drone, and construct a three-dimensional sparse point cloud model according to the parameters;

[0098] S13. Reconstruct the dense point cloud model according to the 3D sparse point cloud model, and construct a 3D model of the coal field based on the 3D reconstruction algorithm and texture mapping according to the dense point cloud model;

[0099] S14. Integrate the selected area in the three-dimensional model to calculate the volume of the coal pile, and calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com