Patents

Literature

48 results about "Structure algorithm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The structured clone algorithm is an algorithm defined by the HTML5 specification for copying complex JavaScript objects. It is used internally when transferring data to and from Workers via postMessage() or when storing objects with IndexedDB.

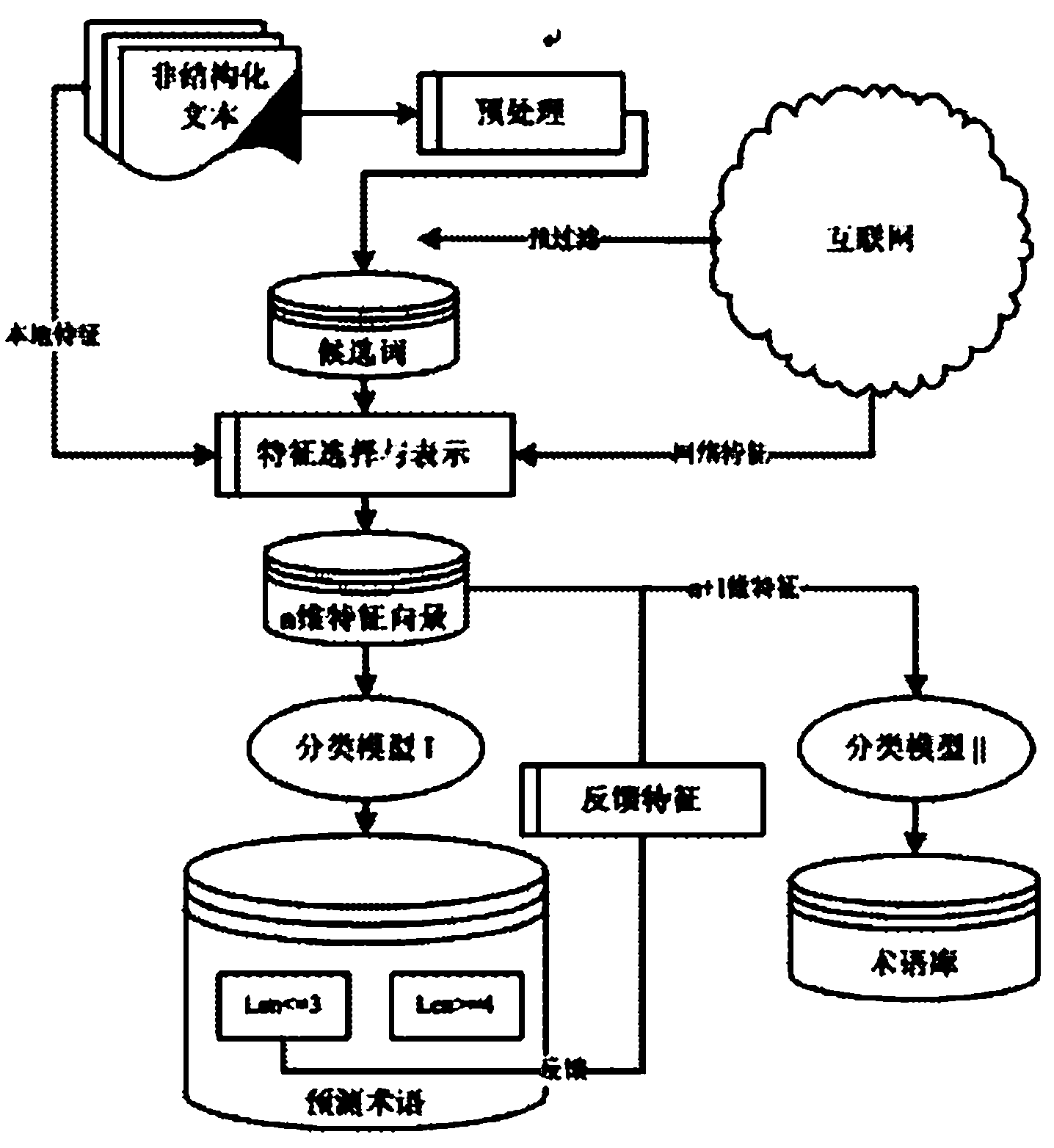

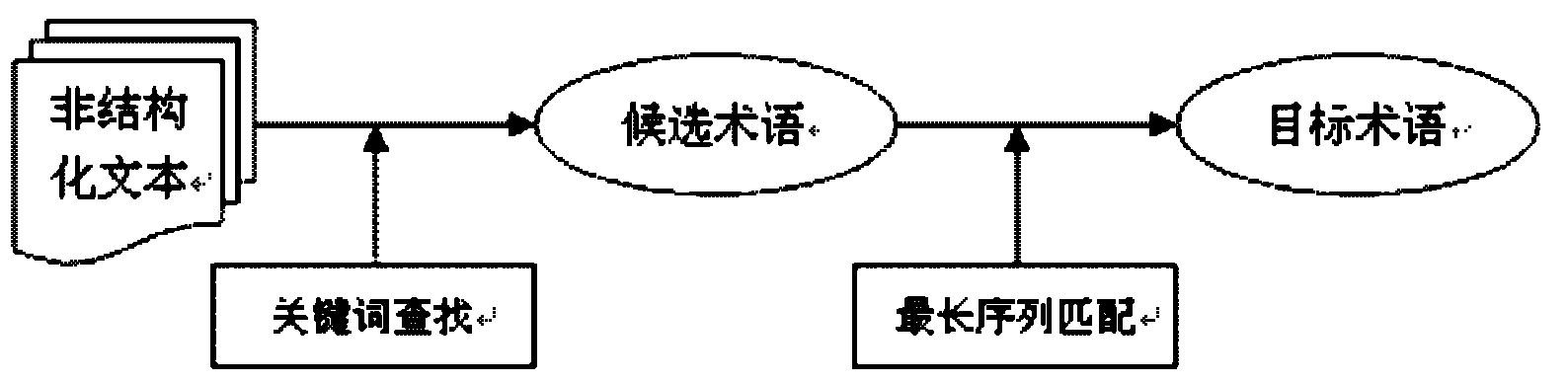

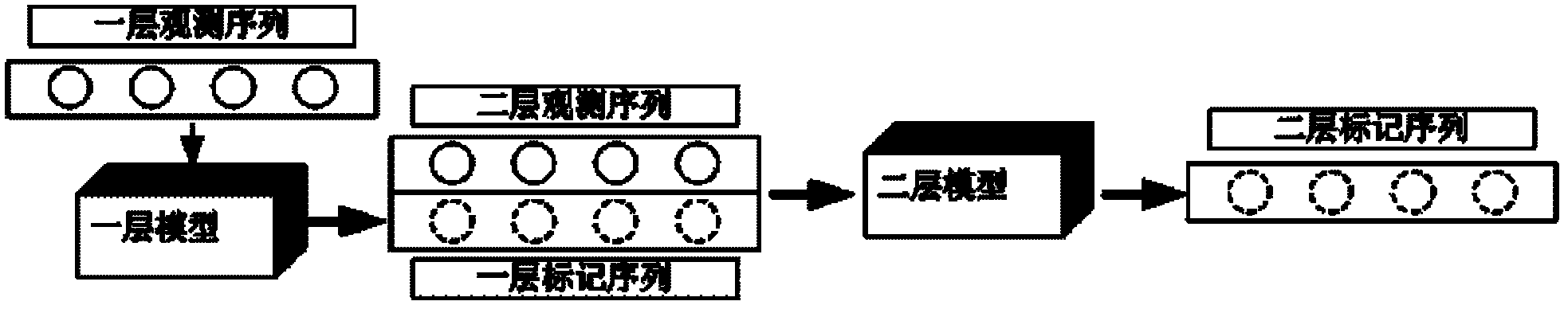

Method for extracting text-oriented field term and term relationship

InactiveCN102360383AEfficient removalImprove term recognitionSpecial data processing applicationsNODALConditional random field

The invention discloses a method for extracting a text-oriented field term and term relationship. The method is characterized by comprising the following steps of: firstly, preprocessing original linguistic data to obtain a candidate word set including clauses, participles and part of speech tagging, and filtering noise words; secondly, extracting term characteristics from the original linguisticdata and the Internet, and separating terms from candidate words by combining with a dual-model structure algorithm; thirdly, constructing a term dictionary by adopting an inverted index method, and tagging the terms in a text to be identified by using a longest match algorithm; and finally, carrying out multilevel sign sequence tagging through a conditional random field model according to a multi-dimensional node signing rule to obtain a relationship among the terms in the text to be identified.

Owner:XI AN JIAOTONG UNIV

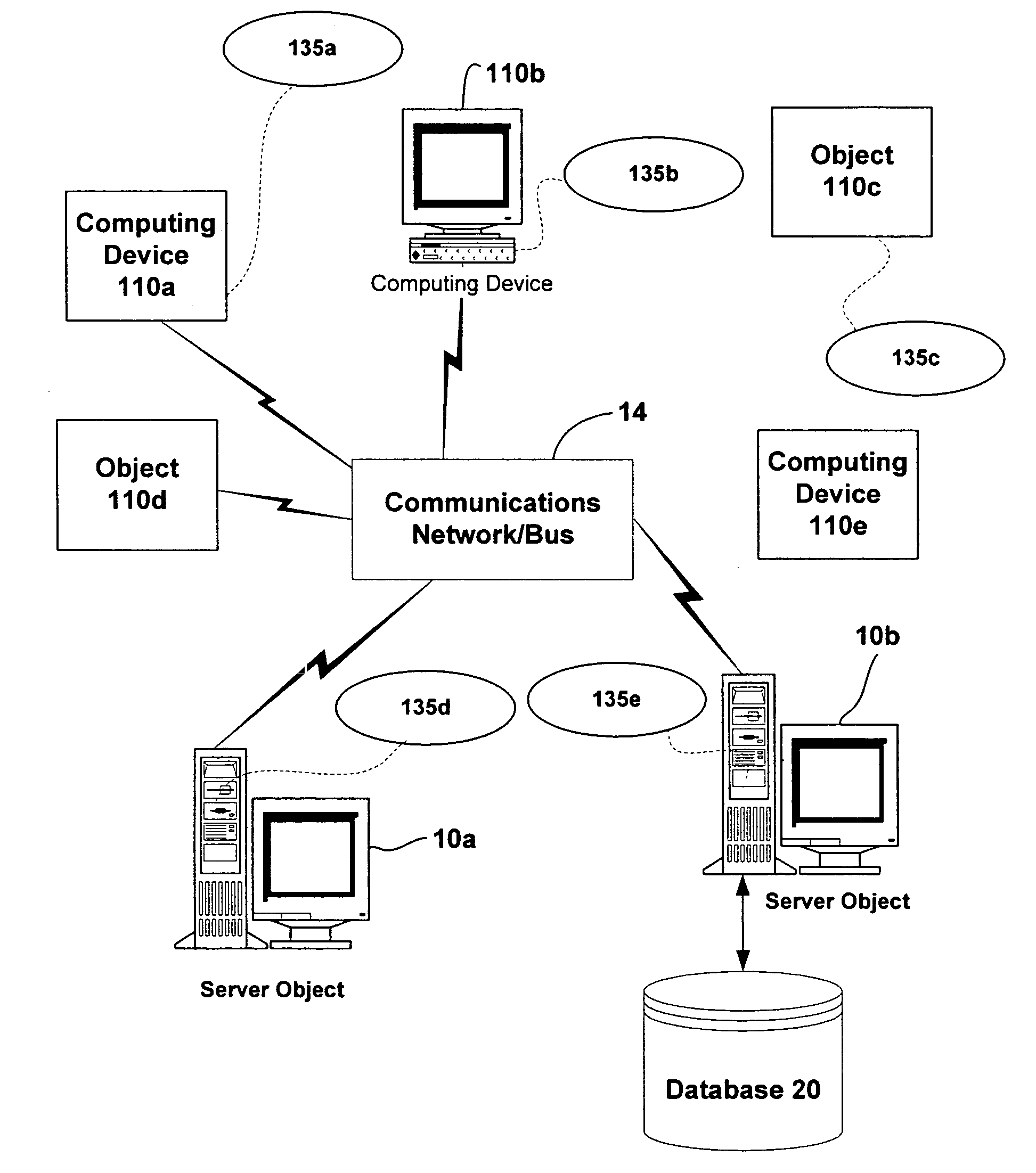

Systems and methods for logging and recovering updates to data structures

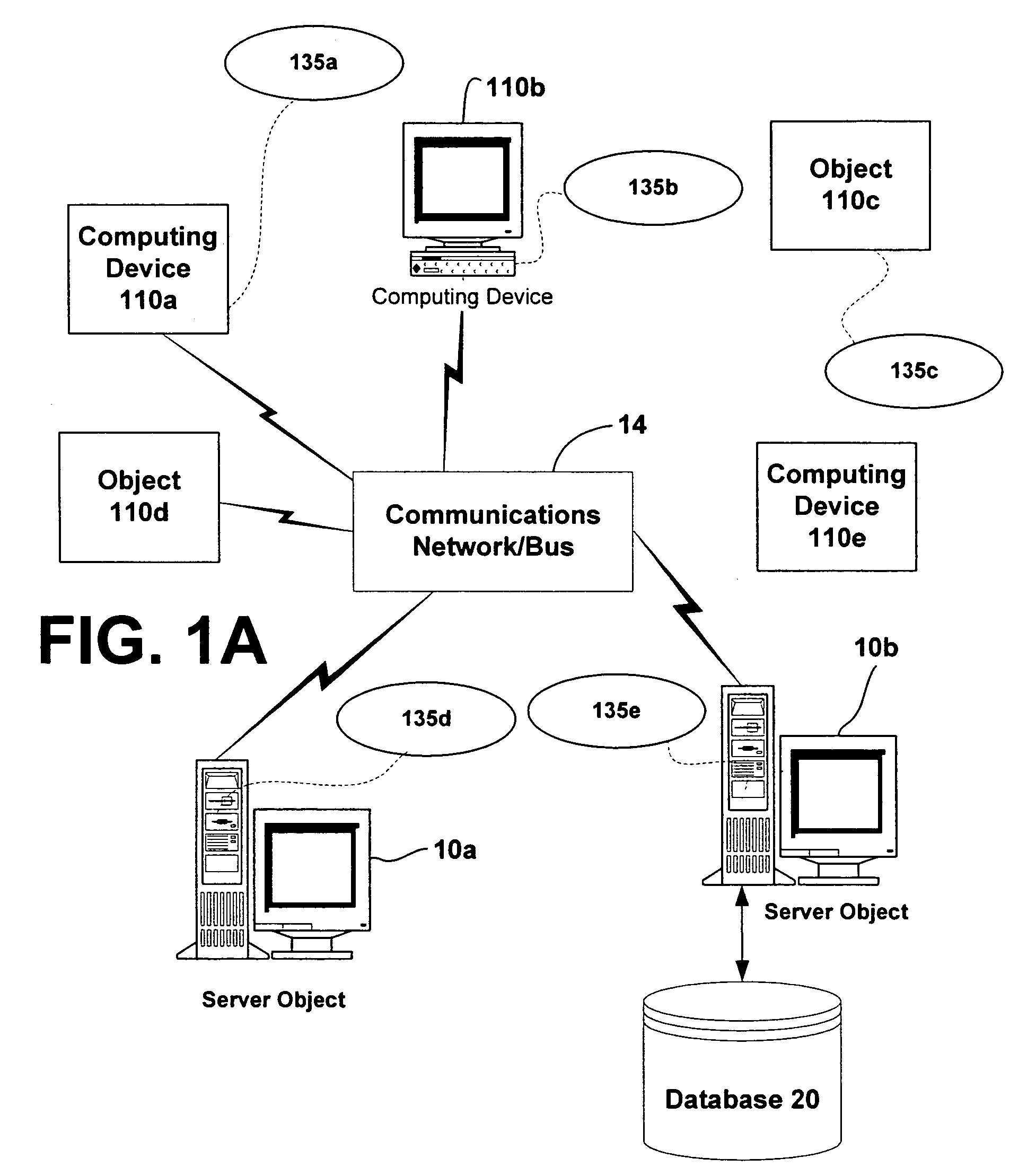

InactiveUS20050071336A1Save spaceDigital data information retrievalDigital data processing detailsFault toleranceClient-side

Systems and methods for logging and recovering updates to data structures in the event of failure of an information management system are provided. In exemplary implementations, methods for implementing an efficient redo log for a data structure that is concurrently accessed by multiple clients is provided. The data structure is implemented in two layers: the data structure algorithm layer which sits atop an allocator that provides distributed, persistent, and replicated storage allocation. Both the B-link tree algorithm layer and the allocator use the service of the logging mechanism to implement fault-tolerance and atomicity guarantees. The present invention uses a single log and allows periodic truncation of that log for space efficiency.

Owner:MICROSOFT TECH LICENSING LLC

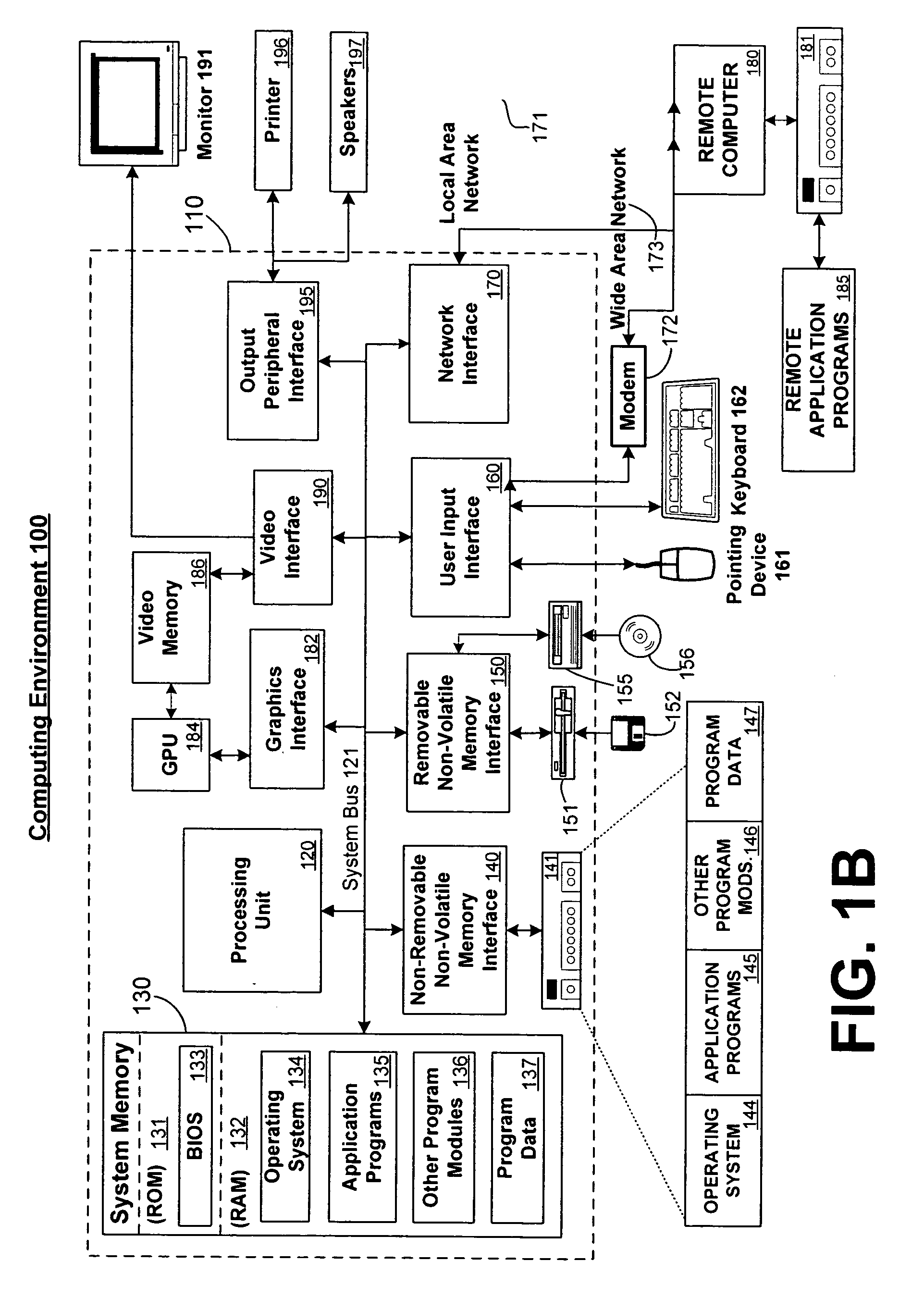

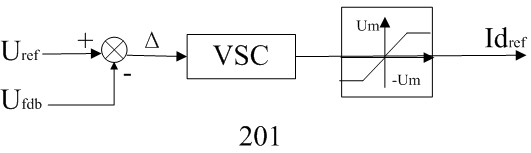

Three-phase voltage type rectifier and control method thereof

InactiveCN102638186AIncrease profitRespond quickly to changeAc-dc conversionControl signalControl algorithm

The invention provides a three-phase voltage type rectifier and a control method thereof. Through providing the high-robustness three-phase voltage type rectifier, a better inhibition effect on both overshooting and steady state error of a system is achieved while the high utilization rate of the voltage of an electric grid is guaranteed. The three-phase voltage type rectifier and the control method thereof have the following advantages: 1, the utilization rate of the electric grid can be increased by 15.4% through adopting an SVPWM (Space Vector Pulse Width Modulation) method compared with that achieved by an ordinary PWM (Pulse Width Modulation) method; 2, a voltage loop adopts a sliding-mode variable structure control (VSC) algorithm to replace the traditional PID (Proportion Integration Differentiation) control algorithm, thus the three-phase voltage type rectifier can rapidly respond to the voltage change of a direct current side; and 3, the voltage loop adopts a PID and VSC combined control method to replace the traditional PID control algorithm, so that the three-phase voltage type rectifier can rapidly respond to current change and can output stable control signals, and then, the overshooting and steady state error of the direct current side are reduced.

Owner:SHANGHAI SANY PRECISION MACHINERY

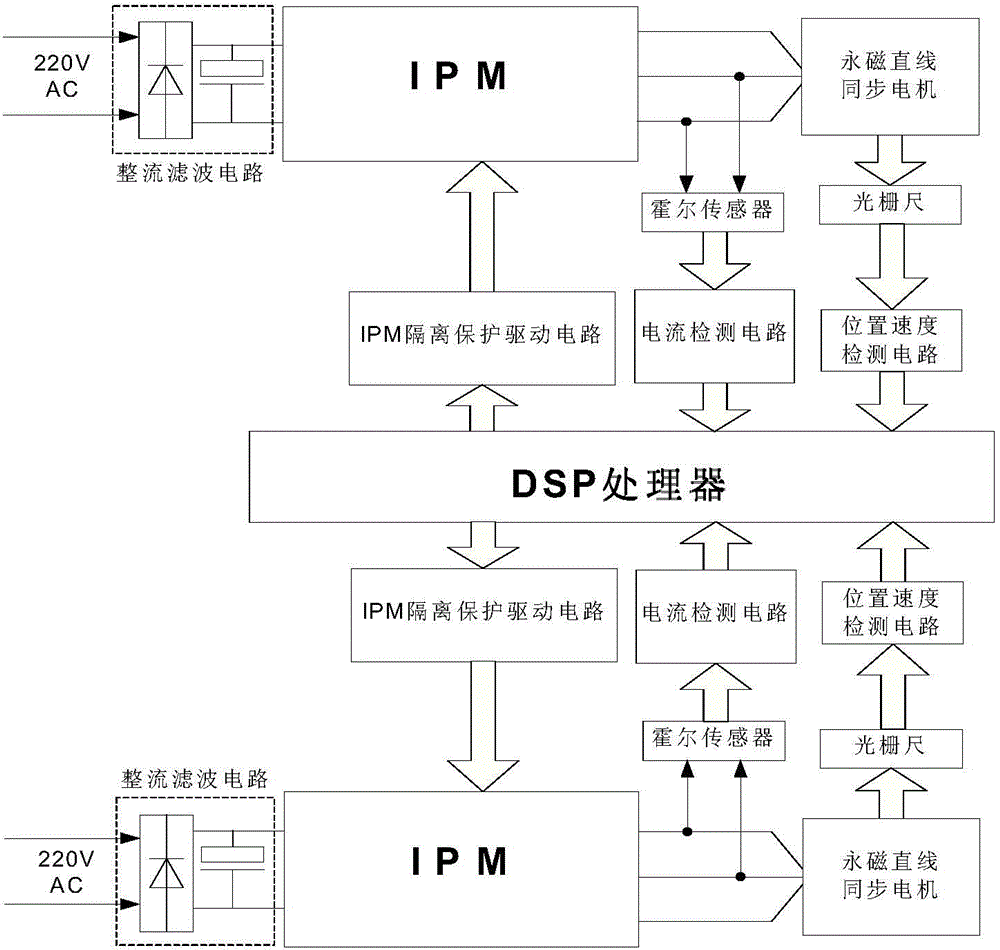

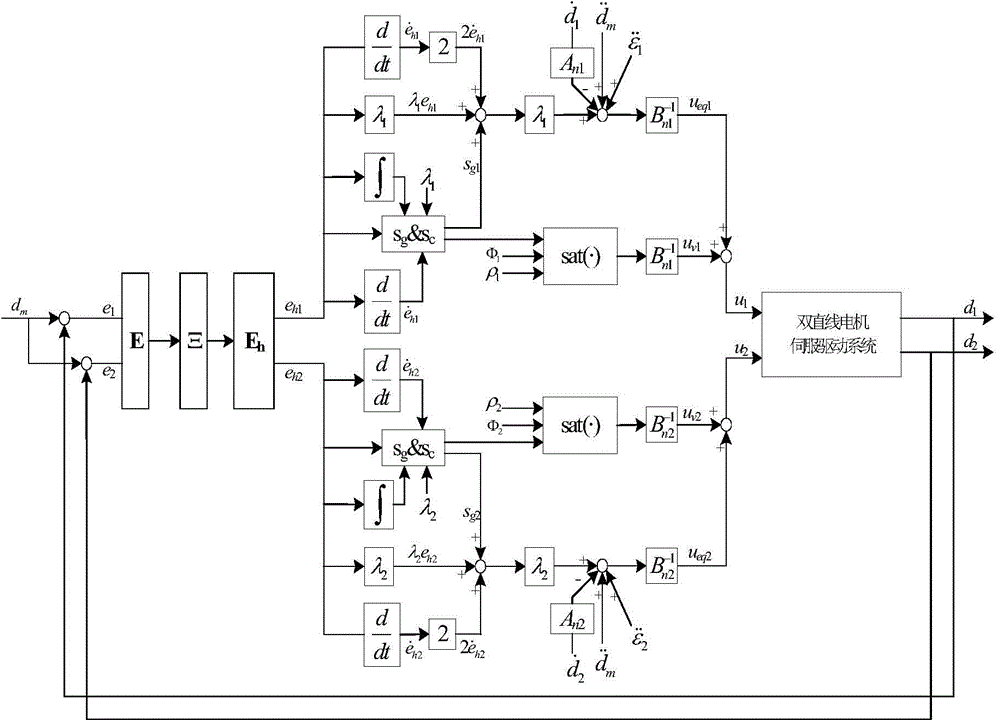

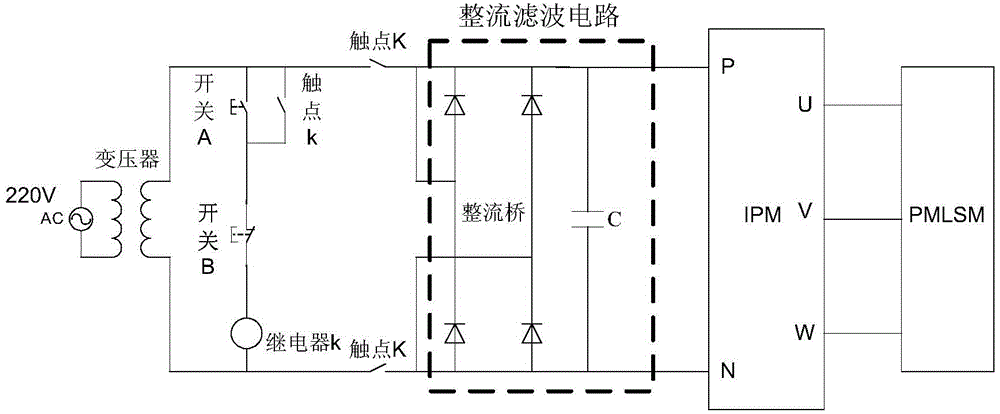

Device and method for controlling gantry numerical control milling machine through double line permanent magnet synchronous motors

InactiveCN103560721AFast convergenceHigh positioning accuracyAutomatic control devicesMultiple motor speed/torque controlStructure algorithmTracking error

The invention provides a device and method for controlling a gantry numerical control milling machine through double line permanent magnet synchronous motors and belongs to the technical field of numerical control. The method comprises the steps that firstly, a position signal is input and at this time, the two line permanent magnet synchronous motors receive the same order signal and start to operate; the actually-measured position, the actually-measured speed and the actually-measured current of a rotor of each line permanent magnet synchronous motor is determined; mixed error is calculated, the complementation sliding mode variable structure algorithm is adopted, the control rate is obtained finally, namely the control currents of the two line permanent magnet synchronous motors are obtained, and the whole calculation process is achieved in a DSP. Two sets of six-path PWM signals are generated by the DSP and drive the two line permanent magnet synchronous motors to operate respectively. According to the method for controlling the gantry numerical control milling machine through the double line permanent magnet synchronous motors, tracking errors of two axes are converted into the mixed error of a double-line-motor servo system through cross coupling control, so that the locating accuracy is improved, compared with a system controlled through a traditional method, the double-line-motor servo system is high in response speed, it is guaranteed that the tracking errors and synchronous errors are converged on zero simultaneously and rapidly, and complementation sliding mode variable structure control still has the characteristic of high robustness of tradition sliding mode control.

Owner:SHENYANG POLYTECHNIC UNIV

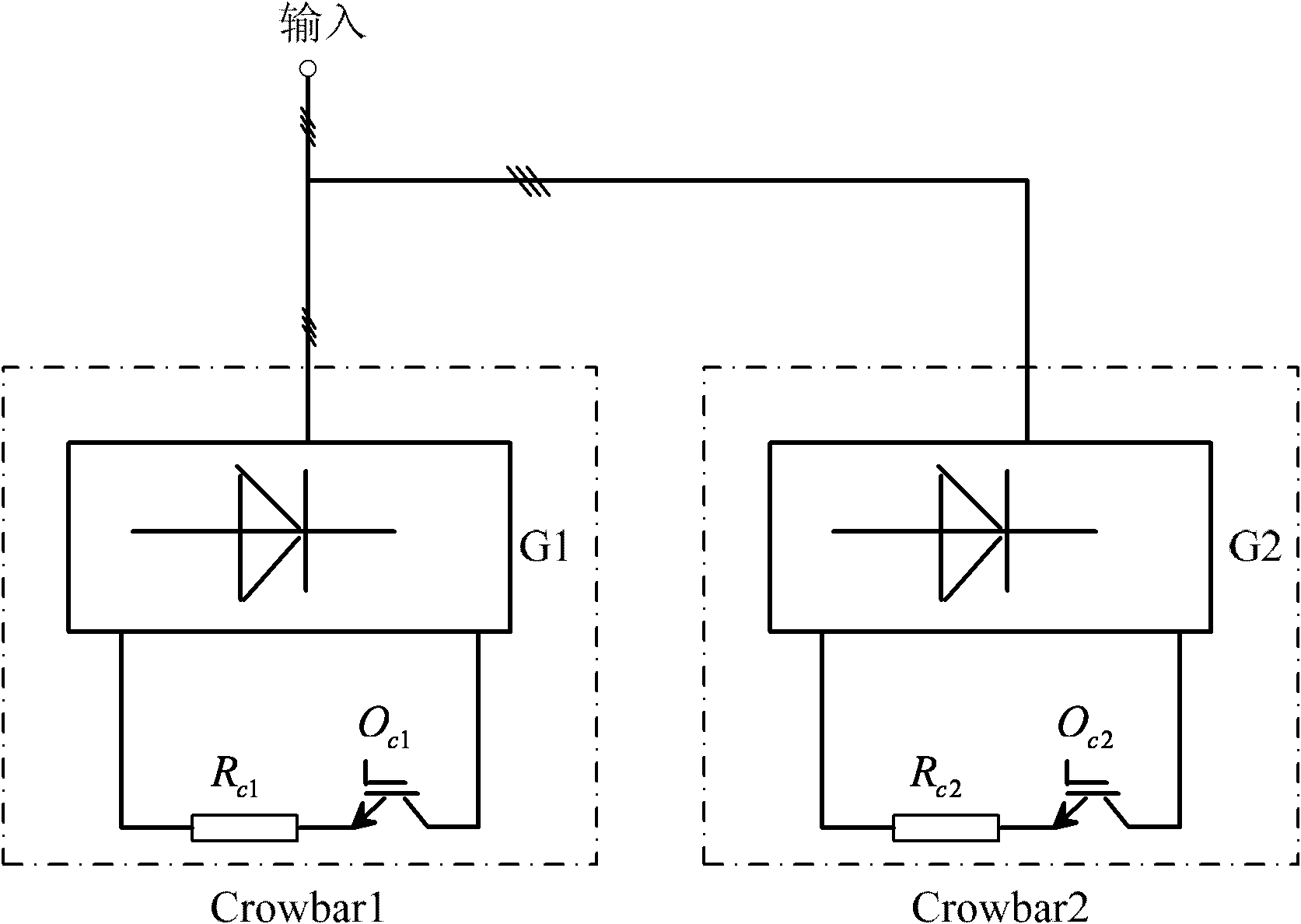

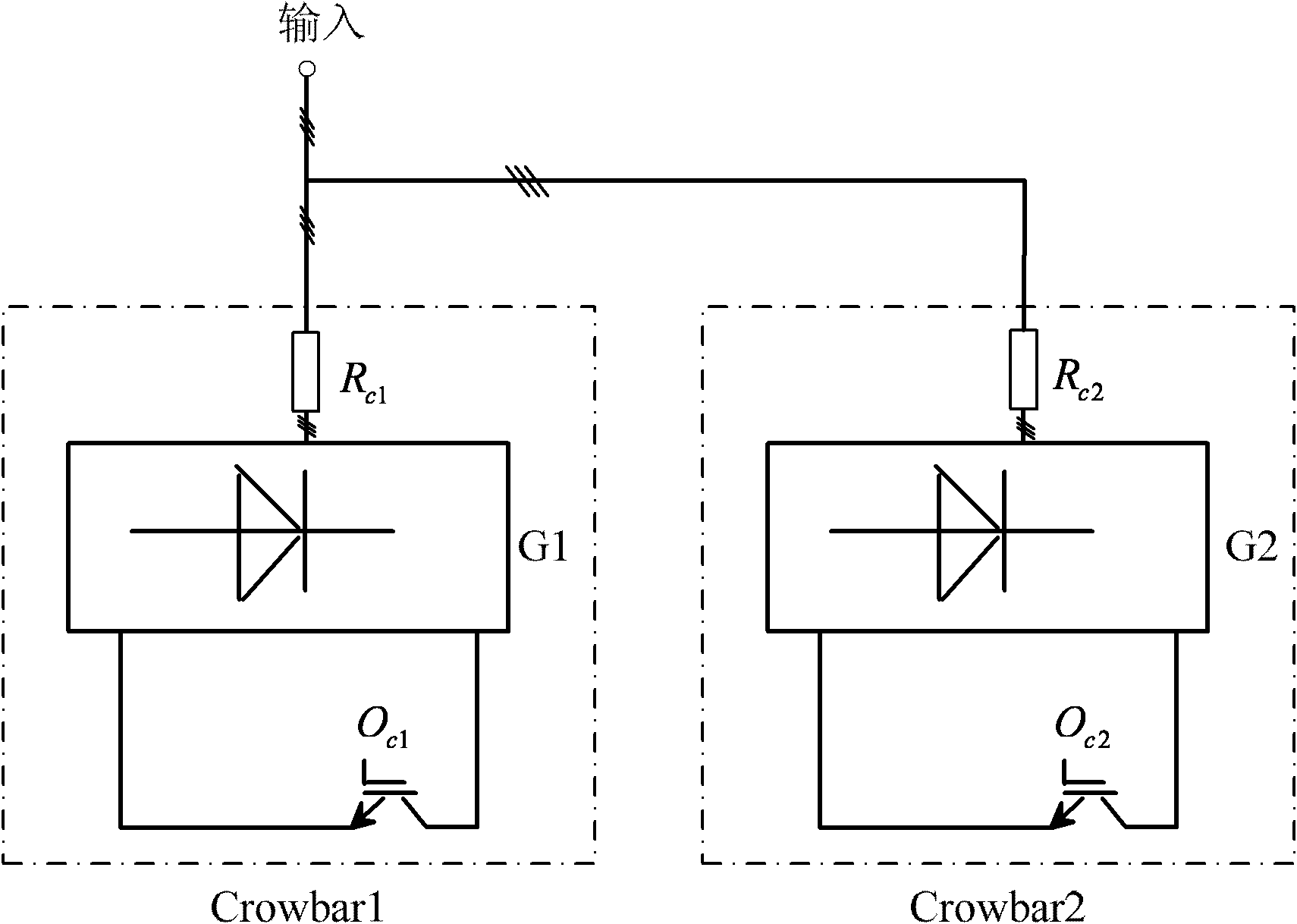

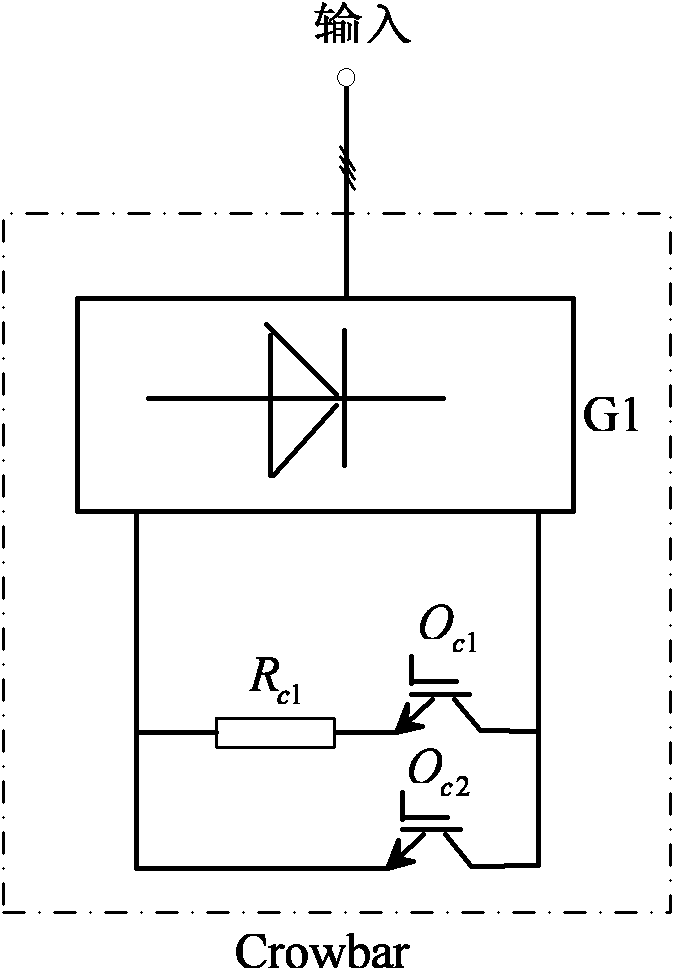

Variable resistor Crowbar structures for low-voltage ride-through of wind power generation and method for realizing variable resistor Crowbar structures

InactiveCN102223126ALow costLittle changeSingle network parallel feeding arrangementsWind energy generationControl signalEngineering

The invention discloses two variable resistor Crowbar structures for the low-voltage ride-through of wind power generation and a method for realizing the variable resistor Crowbar structures. A parallel Crowbar structure comprises two or more than two Crowbars which are connected in parallel and have the very same structure. In a chopped Crowbar structure, two or more than two controllable devices are connected in parallel with an output loop of an uncontrolled bridge, wherein at least one controllable device is connected in series with a bleeder resistor. The method comprises the following steps of: detecting a three-phase grid voltage, a three-phase rotor current and a direct current bus voltage; converting the three-phase grid voltage and the three-phase rotor current to obtain a grid voltage and a rotor current under a two-phase stationary coordinate system, and computing amplitude values of the grid voltage and the rotor current; and by input of the amplitude values of the grid voltage and the rotor current and the direct current bus voltage, and by using a parallel Crowbar structure algorithm or a chopped Crowbar structure algorithm of the variable resistor Crowbar structures with corresponding structures, acquiring control signals of the Crowbars to control the on and off of the controllable devices of the Crowbars respectively.

Owner:北京清能华福风电技术有限公司

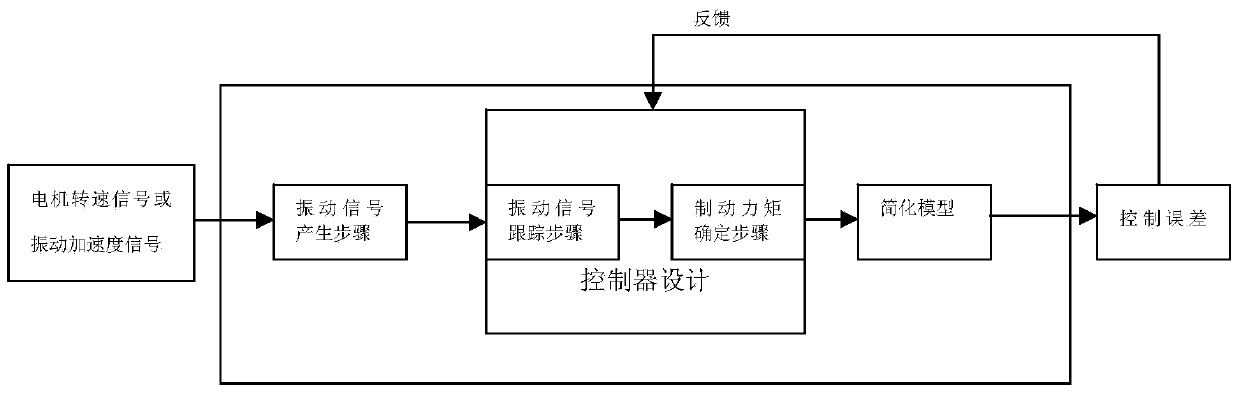

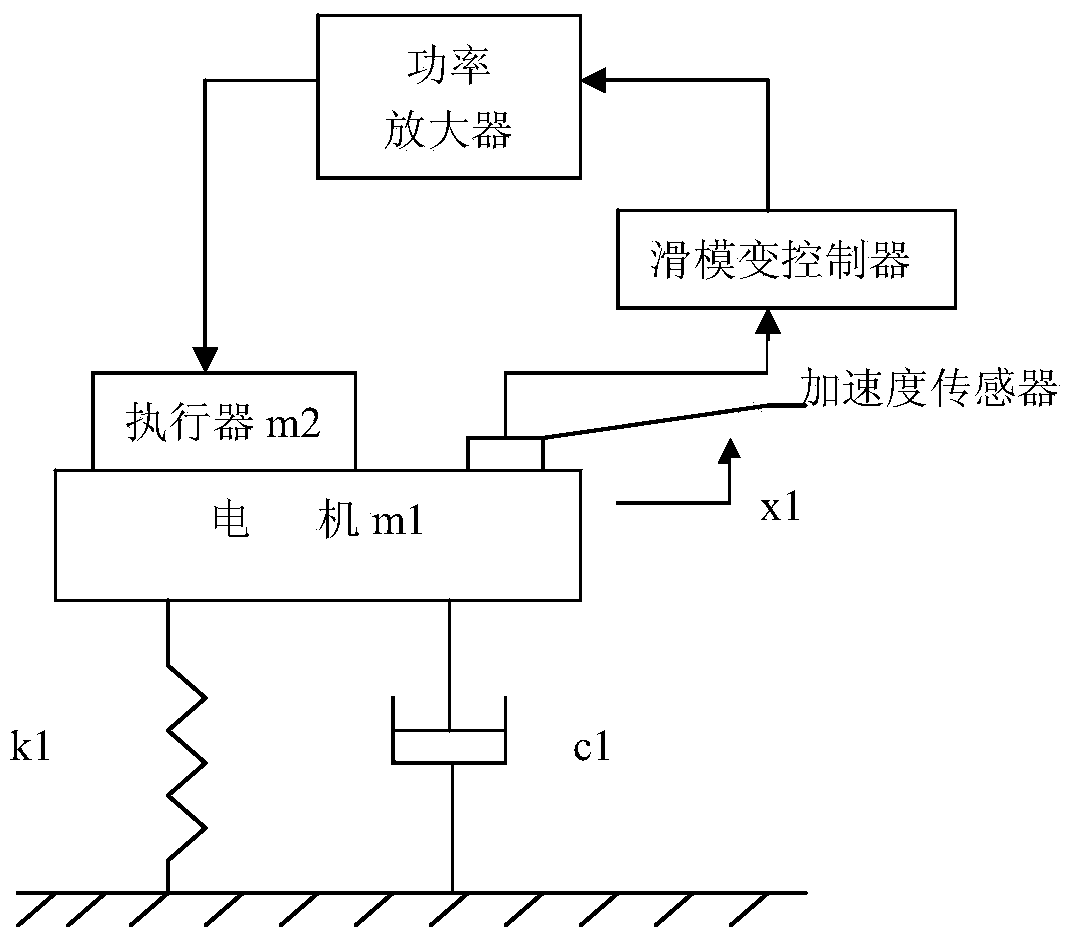

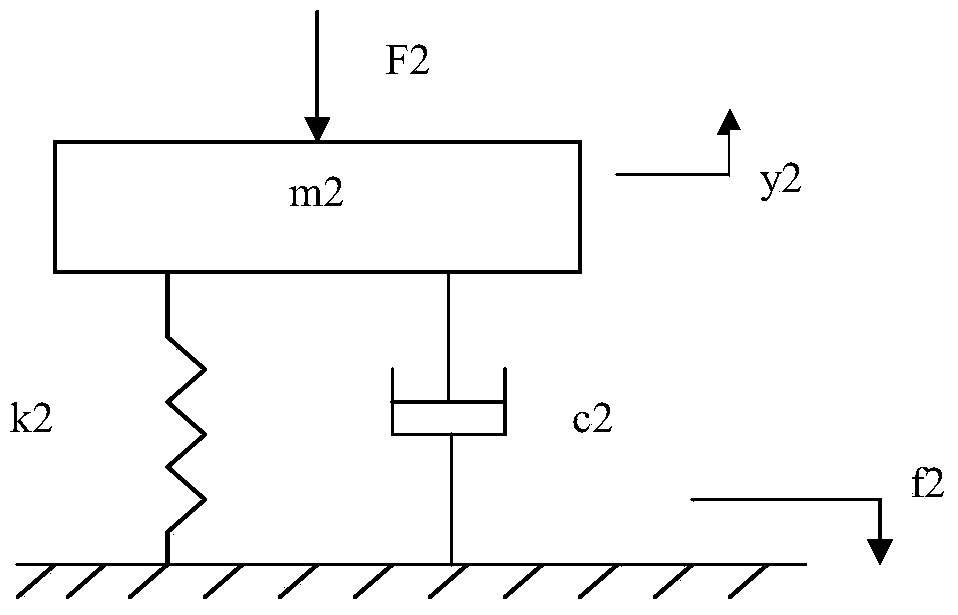

Active control method for low-frequency vibration of electric drive system

ActiveCN103746630AAvoid shockGood vibration dampingMechanical oscillations controlMotor control for motor oscillations dampingMode switchingControl algorithm

The invention discloses an active control method for low-frequency vibration of an electric drive system. The active control method is characterized by comprising the following steps: determining a control scheme, measuring the rotating speed or acceleration of a motor according to the low-frequency vibration characteristic of the electric drive system, and designing an active control strategy; selecting a control algorithm, comparing the characteristics and current application statuses of various intelligent control algorithms, and determining a sliding mode variable structure control algorithm; defining a variable structure switching function, designing a variable structure control rate, exploring a key problem in the application of the sliding mode variable structure algorithm, namely, the root cause of vibration, and reasonably designing a switching function and a control rate; optimizing a switching function parameter according to a genetic algorithm, and applying a genetic algorithm thought to the optimization of the switching function parameter of a sliding mode variable structure in order to further eliminate vibration caused by sliding mode switching; determining a braking torque, and tracking a vibration signal through a controller to provide a brake torque for realizing active control on the low-frequency vibration of the electric drive system. The active control method has the advantages of good control effect, high adaptability and the like.

Owner:BEIHUA UNIV +3

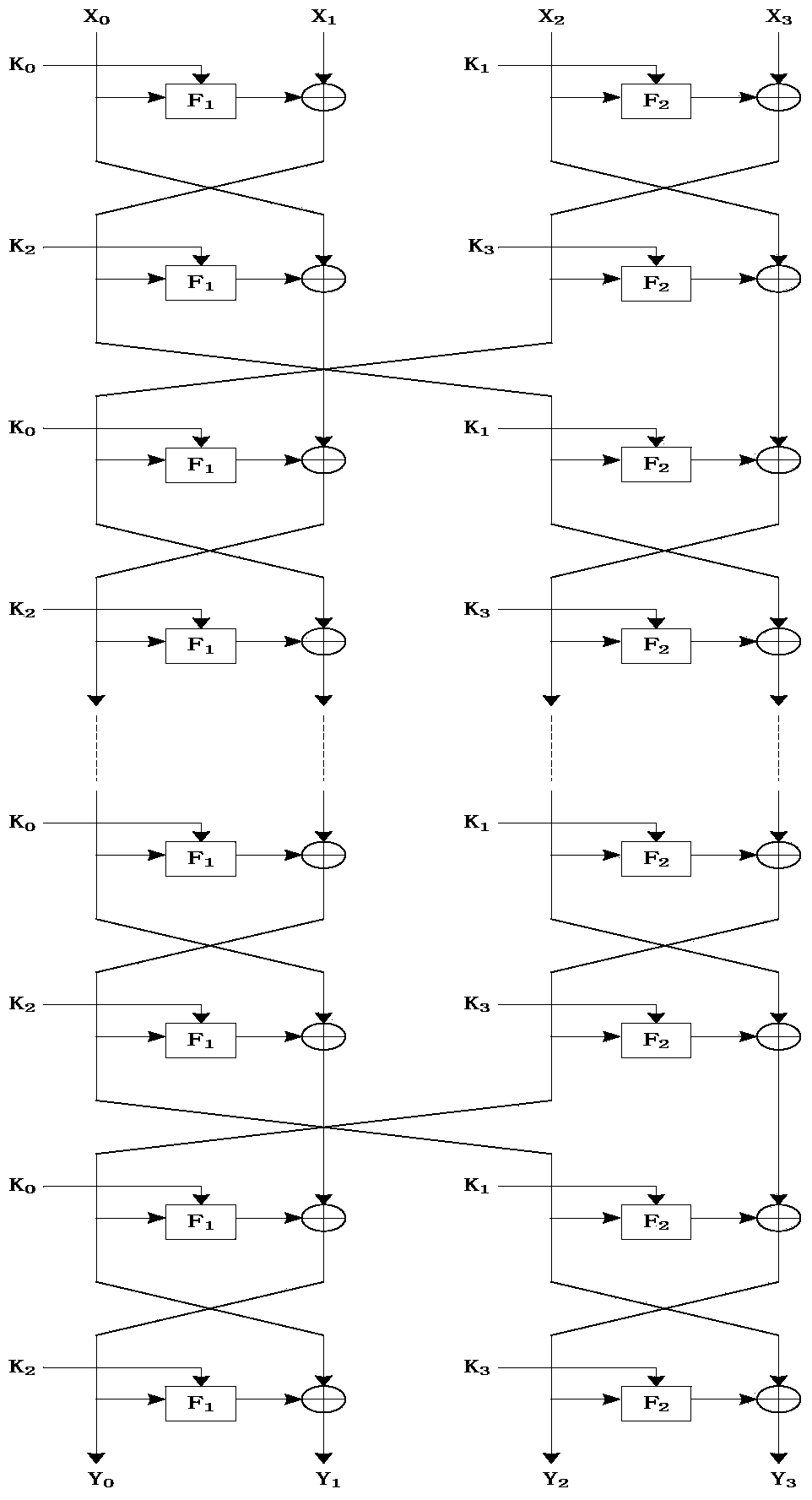

Novel ultra-lightweight QTL (Quasi-Transmission Line) block cipher implementation method

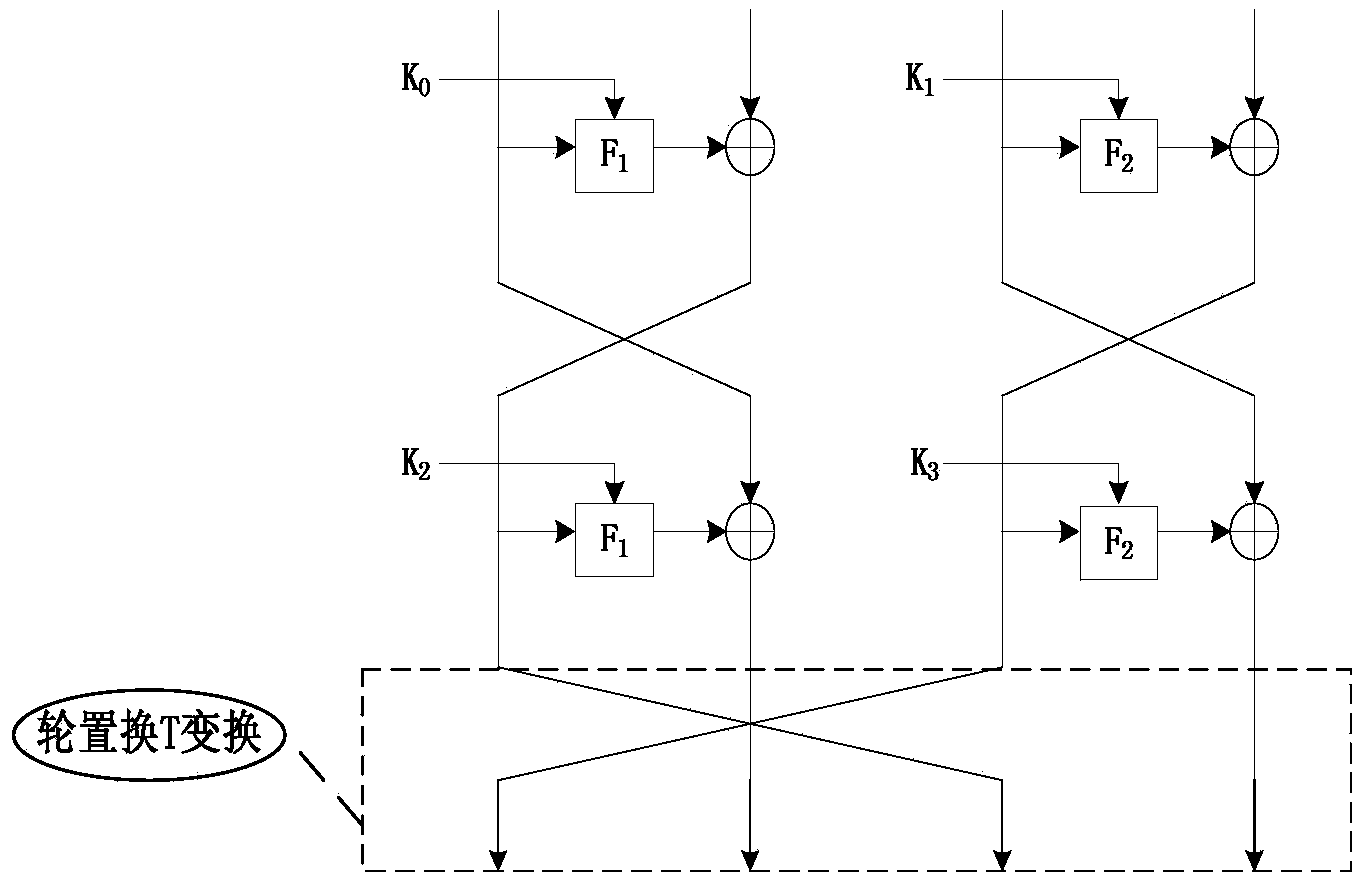

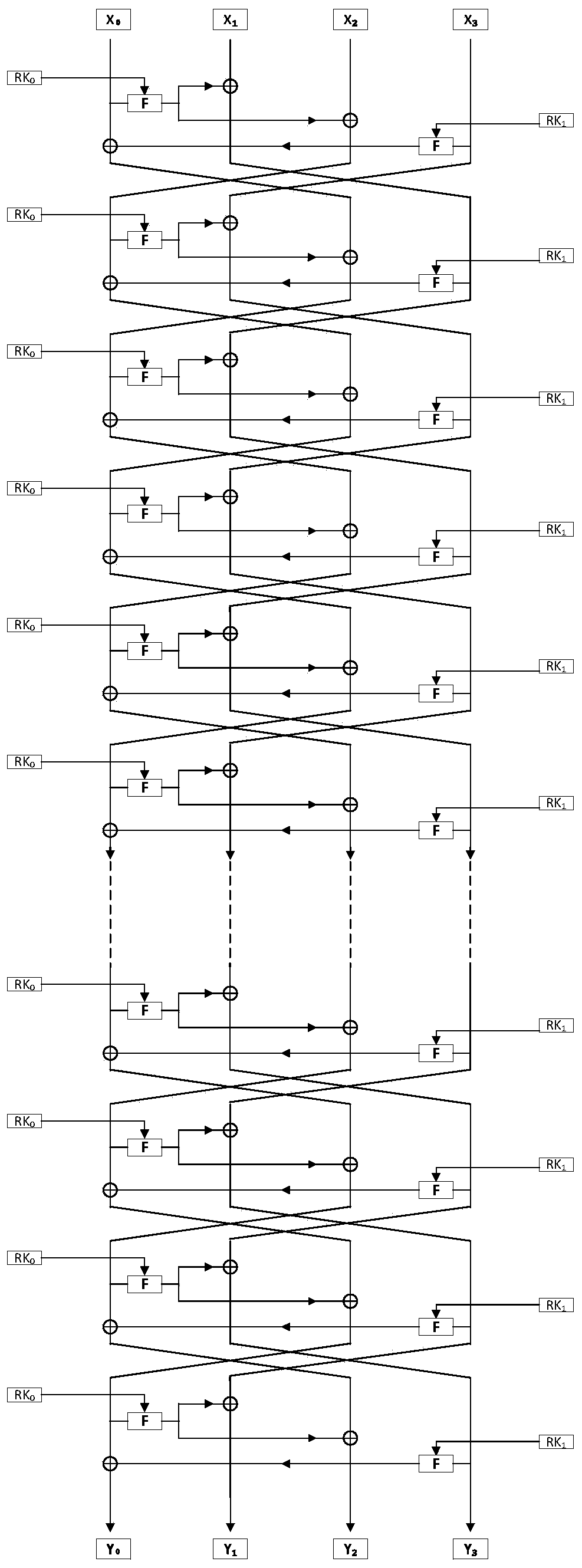

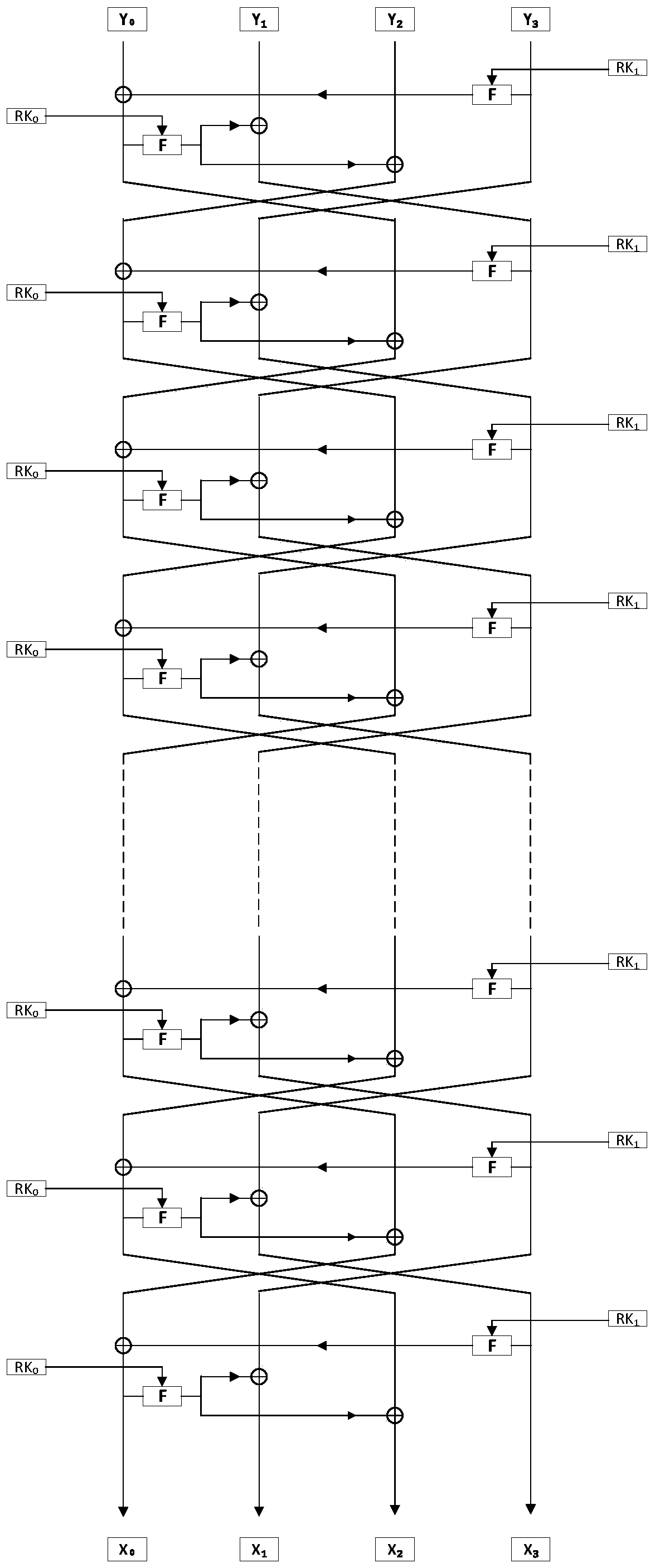

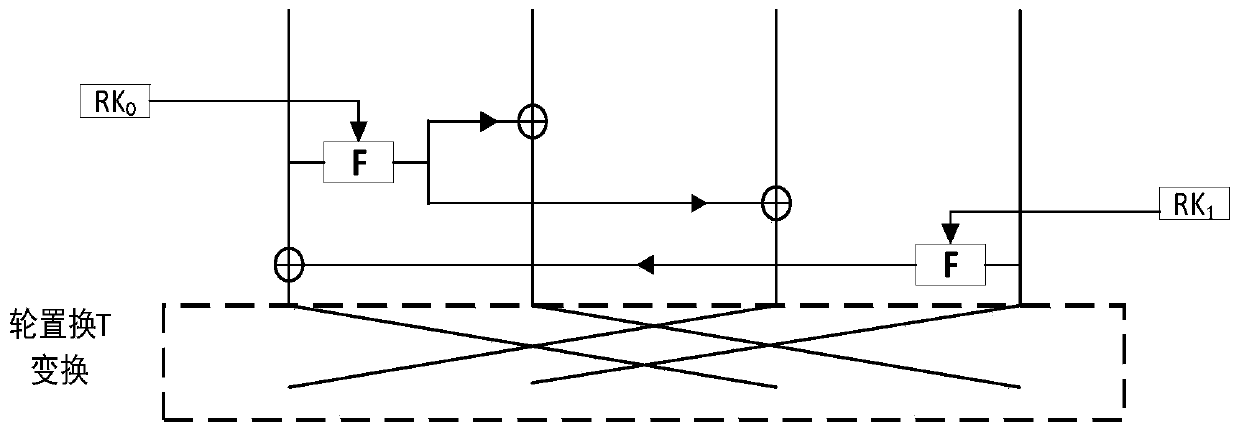

ActiveCN104333446AImprove diffusivitySimple and fast operationEncryption apparatus with shift registers/memoriesComputer hardwareS-box

The invention discloses a novel ultra-lightweight QTL (Quasi-Transmission Line) block cipher implementation method. According to the method, a novel generalized Feistel network structure is designed; the structural algorithm overcomes the defect that only a half of grouped data is changed during one-round iterative operation of the conventional Feistel network structure, and realizes that all grouped data is changed by the one-round iterative operation. F functions in the round operation of the algorithm comprise an F1 function and an F2 function; S1 and S2 boxes are adopted respectively; the conversion process of the F functions comprises round key add, S box substitution, P replacement and S box substitution; different S box and P replacement only requires hardware connection; the F function of the light super S box is constructed. The algorithm structure is highly symmetric, an encryption module is decrypted and multiplexed by the algorithm, decryption can be performed by exchanging an encryption round key use sequence, the operation is easy and convenient, and extra resource is not required to be consumed by the decryption. Compared with the current lightweight password, the occupied resource is smaller, the encryption performance is high, and known attack can be resisted.

Owner:HENGYANG NORMAL UNIV

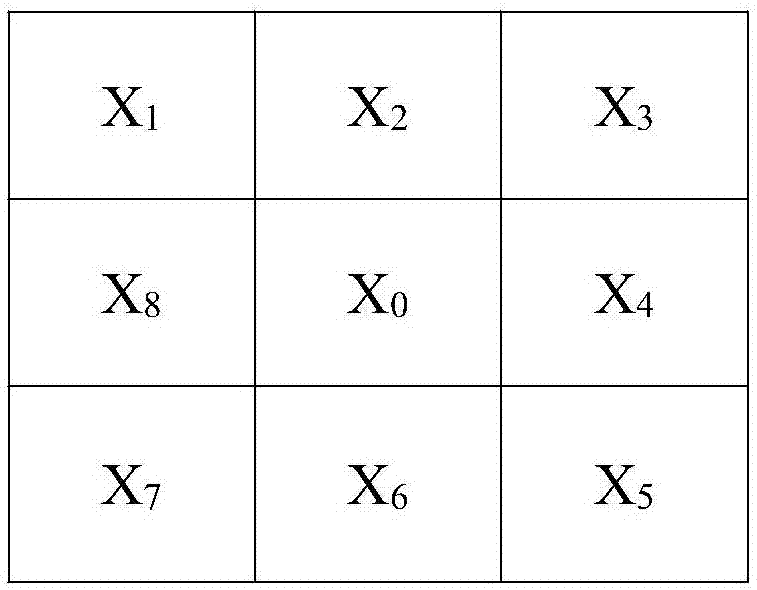

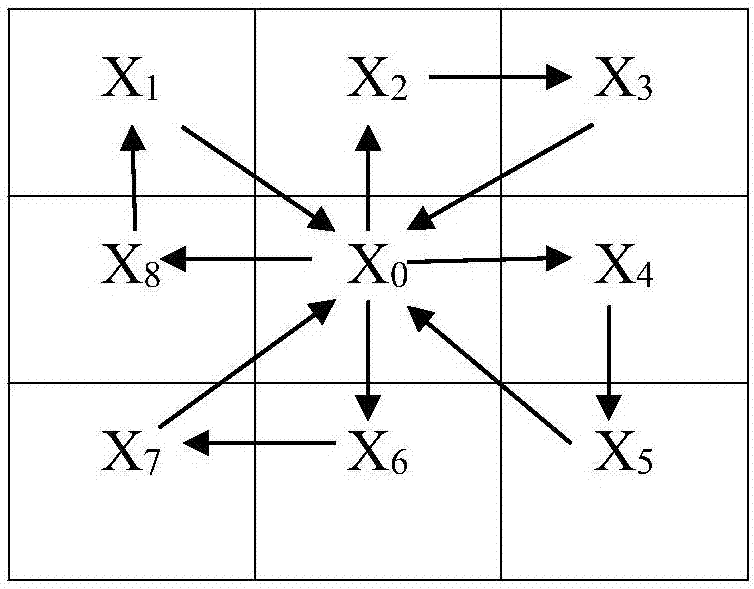

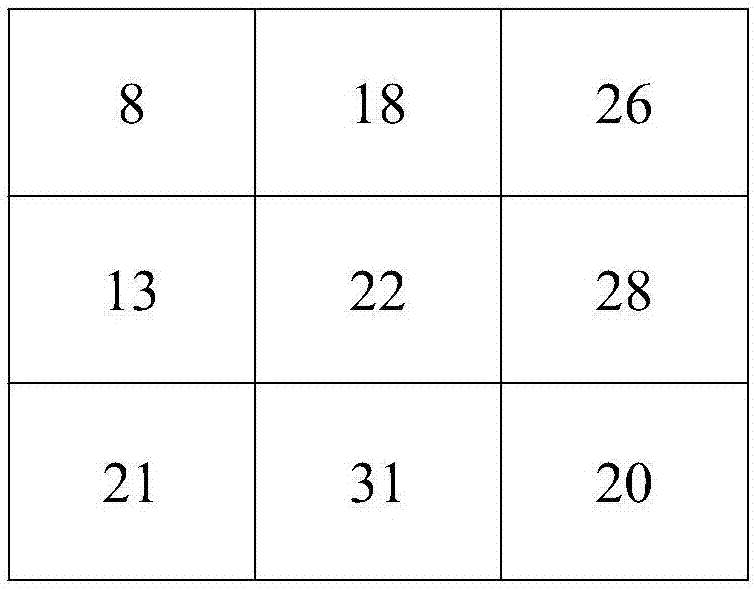

Face recognition feature extraction algorithm based on local cyclic graph structure

InactiveCN107358147ATake advantage ofAccurate descriptionCharacter and pattern recognitionPattern recognitionGrayscale

The invention relates to a face recognition feature extraction algorithm based on a local cyclic graph structure. The algorithm is mainly characterized by selecting a 3 * 3 neighborhood in a face grayscale image and setting corresponding pixel values; cyclically constructing a graph structure in the selected neighborhood in a certain order; successively comparing the pixel values according to the order of the graph structure along the direction of an arrow, and expressing a result in binary; and calculating the characteristic value of the central pixel in the neighborhood. The algorithm is reasonable in design, can accurately describe facial features, provides the obtained characteristic value of the target pixel with more representativeness, and improves a recognition rate. The obtained characteristic value describes the characteristic information of a facial image comprehensively so as to be capable of face recognition. Further, the algorithm has advantages over a symmetrical local graph structure algorithm based on multi-directional weight optimization in terms of time consumption.

Owner:TIANJIN UNIV OF SCI & TECH

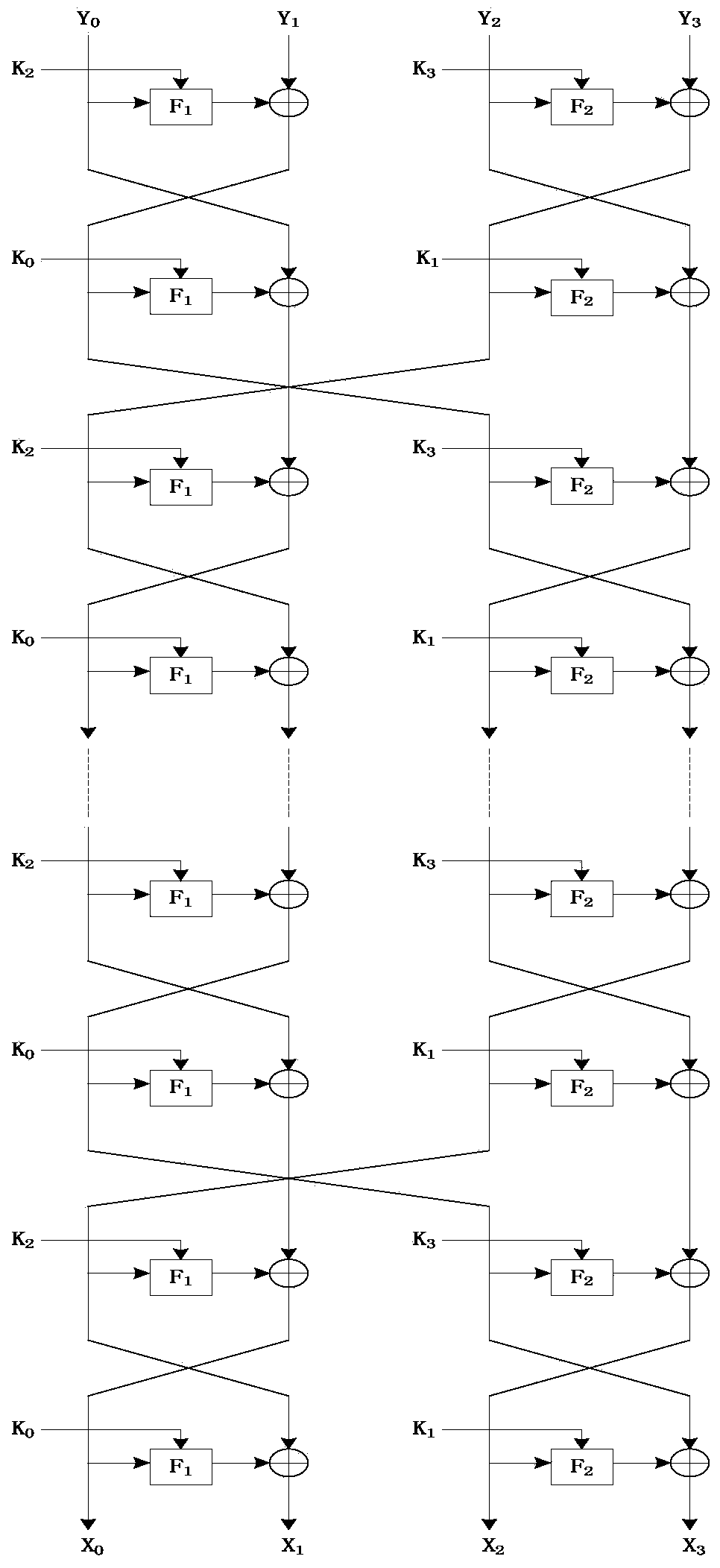

Implementation method of novel lightweight block cipher CORL

ActiveCN111431697AImprove diffusivitySave resourcesEncryption apparatus with shift registers/memoriesAlgorithmControl signal

The invention discloses an implementation method of a novel lightweight block cipher CORL. According to the method, a novel generalized Feistel network structure is designed, the structural algorithmoptimizes the defect that a round of iterative operation of a traditional Feistel network structure only changes a half of data packet data, and achieves an effect that three fourths of packet data ischanged through a round of iteration. An algorithm round function comprises an F function, and the conversion process of the F function sequentially comprises row shifting, round key addition, S boxreplacement, row shifting and column confusion. The algorithm structure is convenient for software and hardware realization, the algorithm decryption basically multiplexes the encryption module, decryption can be performed only by adding some control signals, the operation is simple, and decryption is realized without consuming more resources. Compared with the current block cipher, the occupied resource is small, the encryption performance is high, and the known attack can be resisted.

Owner:HENGYANG NORMAL UNIV

An unmanned aerial vehicle aerial photography modeling method based on a BIM technology

InactiveCN109410330AWide coverageSolving Major General UAV aerial photographyDetails involving processing stepsResource allocationSimulationShop drawing

The invention provides an unmanned aerial vehicle aerial photography modeling method based on a BIM technology, and the method comprises the following specific implementation steps: 1, carrying out the aerial photography of an unmanned aerial vehicle, collecting the related information of an on-site construction drawing, and obtaining the landform and on-site conditions of a project based on a motion recovery structure algorithm and scale invariant feature conversion; 2, completing later-stage GIS data processing of the aerial survey by adopting ContextCapture; 3, a local area network is built, and GIS data are processed in a cluster mode; Step 4, importing the model raw material data into revit software to generate a three-dimensional model; and 5, arranging on-site temporary constructionand planning construction routes and specific construction schemes by using the geomorphic model generated by revit software in combination with the design drawing. Aerial photography modeling of theunmanned aerial vehicle is well utilized based on the BIM technology, rapid and accurate modeling is achieved, the modeling mode is more convenient, the model culvert surface is wider, daily aerial photography of the unmanned aerial vehicle is achieved, the modeling progress is dynamically followed, and construction is guided.

Owner:CHINA MCC17 GRP

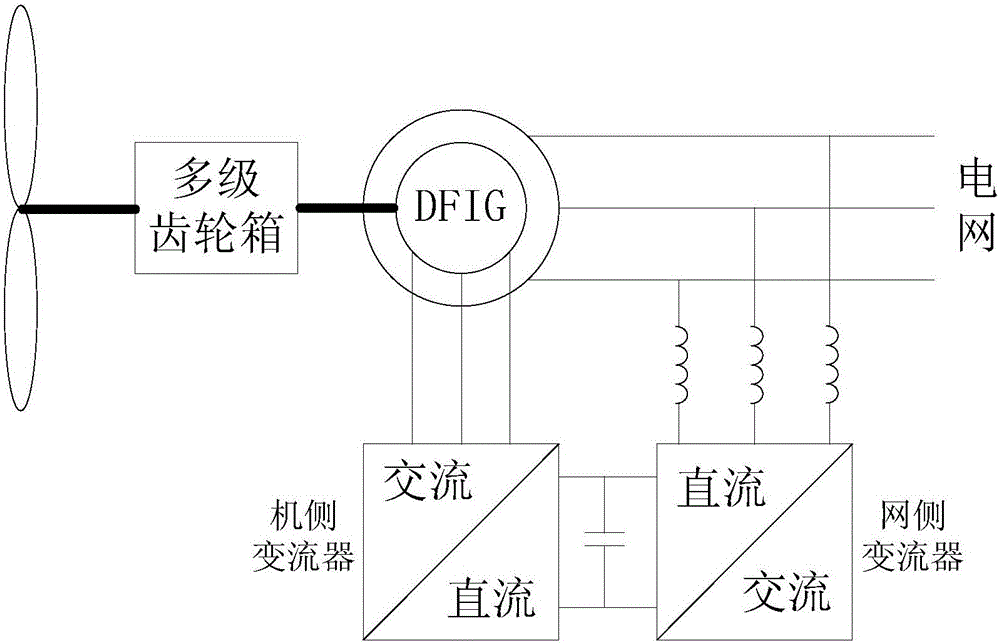

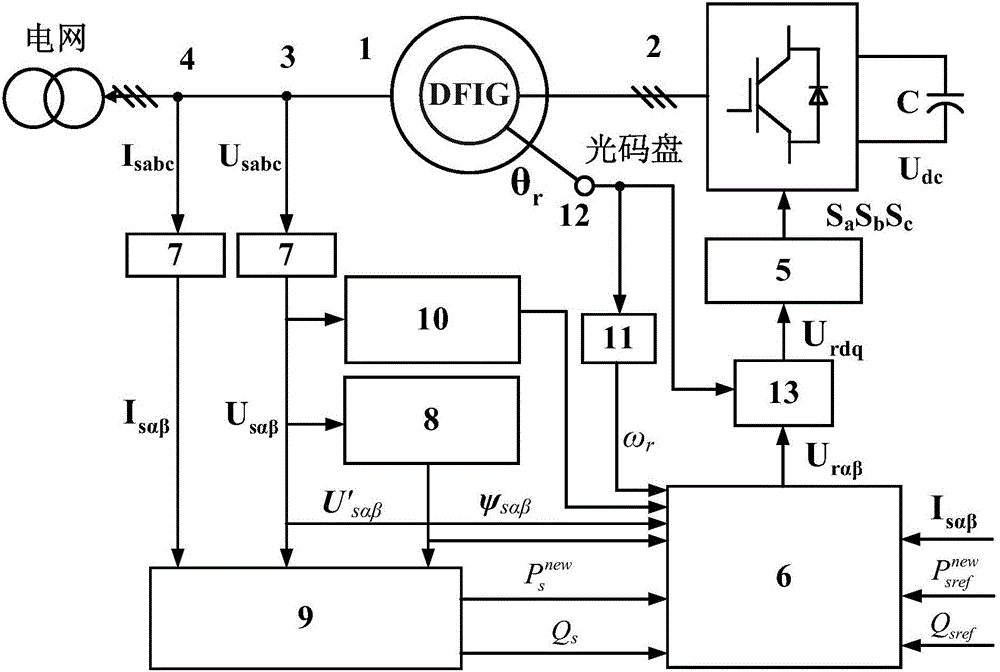

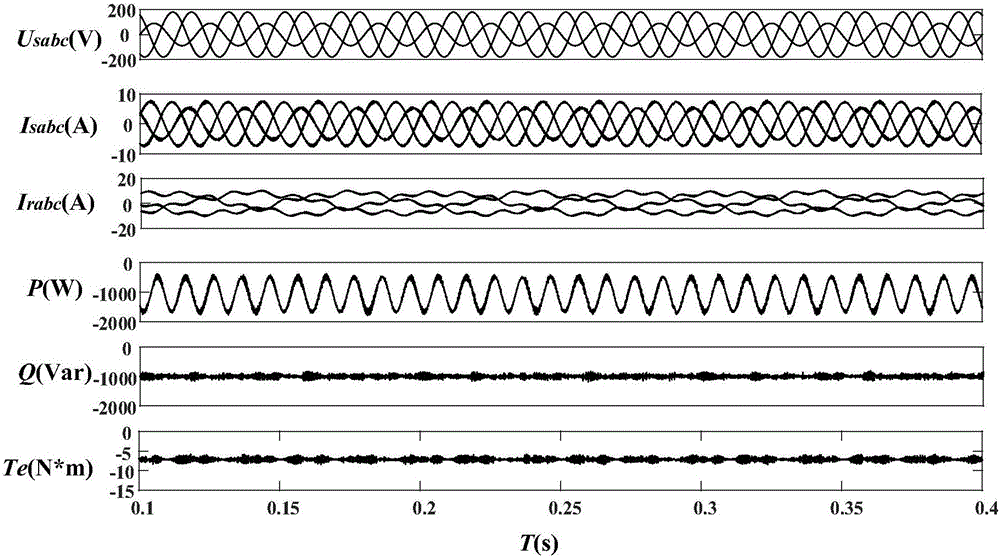

Extended active power-based sliding mode variable structure direct power control (DPC) method for DFIG in unbalanced power grid

ActiveCN106452263AEffective controlFrequency real-time monitoringElectronic commutation motor controlVector control systemsPower flowMathematical model

The invention discloses an extended active power-based sliding mode variable structure direct power control (DPC) method for a DFIG in an unbalanced power grid. Extended active power is provided on the basis of a mathematical model of the DFIG in the unbalanced power grid, the extended active power and conventional reactive power are taken as control objects, a sliding mode variable structure algorithm and a DPC technology are combined, and an improved extended active power-based sliding mode variable structure DPC strategy is further provided. According to the method, the DFIG in the unbalanced power grid can be effectively controlled to obtain stable electromagnetic torque and reactive power as well as sinusoidal stator current on the premise of no positive and negative sequence separation of the voltage and current of the power grid; control can be systematically implemented simply without monitoring the frequency of the voltage of the power grid in real time by a phase-locked loop.

Owner:ZHEJIANG UNIV

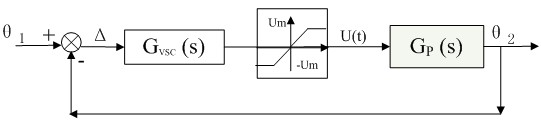

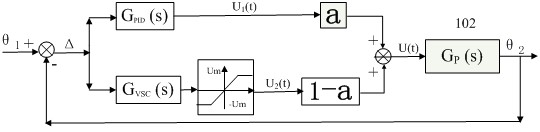

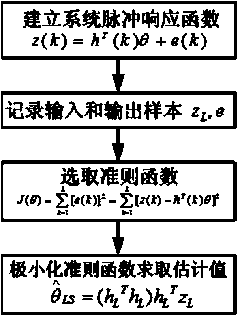

Method for performing position servo driving on electro-hydraulic proportional valve based on hybrid control

ActiveCN103995463AAvoid driftingHigh control precisionControllers with particular characteristicsLinear controlEngineering

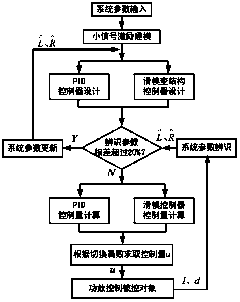

The invention discloses a method for performing position servo driving on an electro-hydraulic proportional valve based on hybrid control in order to increase control accuracy and response speed of the electro-hydraulic proportional valve in position servo occasions. The method is characterized in that a hybrid control method based on PID and sliding mode variable structure algorithms is adopted according to position servo driving of the electro-hydraulic proportional valve, namely a PID controller is utilized to improve position instruction control accuracy of a proportional valve servo system when the system is in a steady state, a sliding mode variable structure nonlinear controller is utilized to improve instruction response and disturbance inhibiting ability of the system when an instruction of the system changes severely and disturbance is large, online identification is performed on the system through a recursive least square algorithm, system parameters are updated, and design of the PID and sliding mode variable structure controllers is performed in real time. The method has the advantages of being high in response speed and steady accuracy, strong in robustness and capable of effectively compensating nonlinear links in the proportional valve, and can be used for improving driving accuracy of the proportional valve.

Owner:SHANDONG DAHAI NEW ENERGY DEV

Building volume measurement method based on UAV picture

InactiveCN109870106AVolume measurement is quick and easyHigh precisionUsing optical meansPoint cloudRelaxation (iterative method)

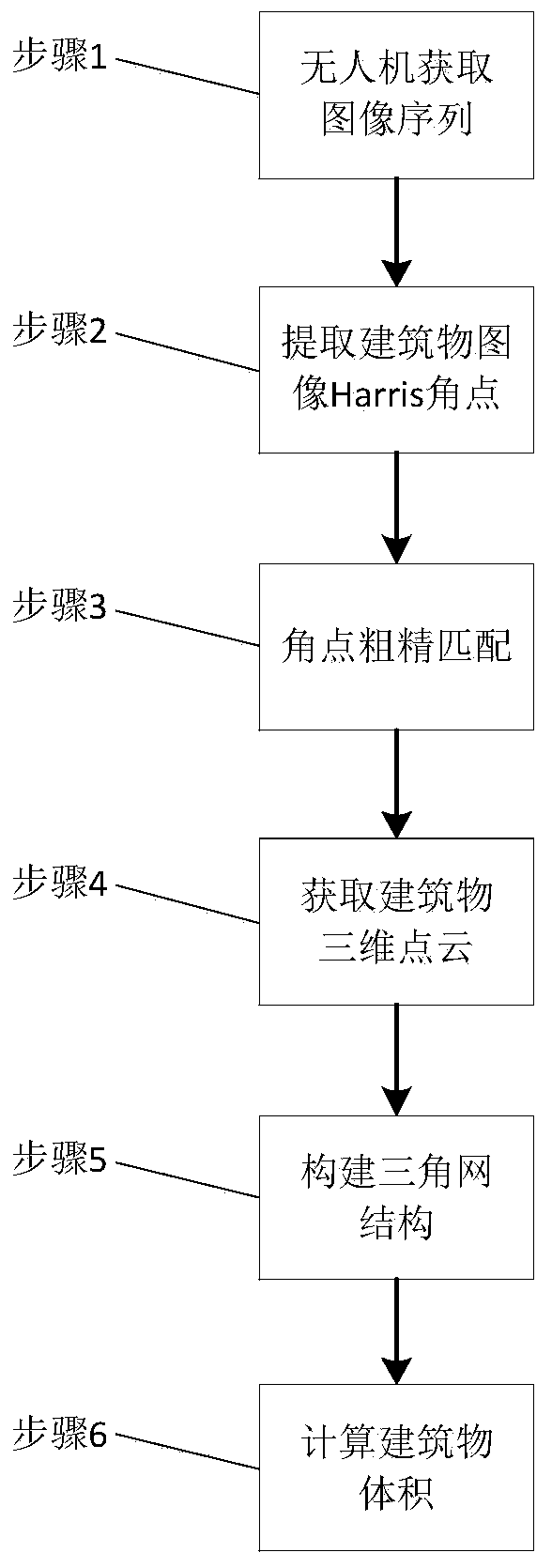

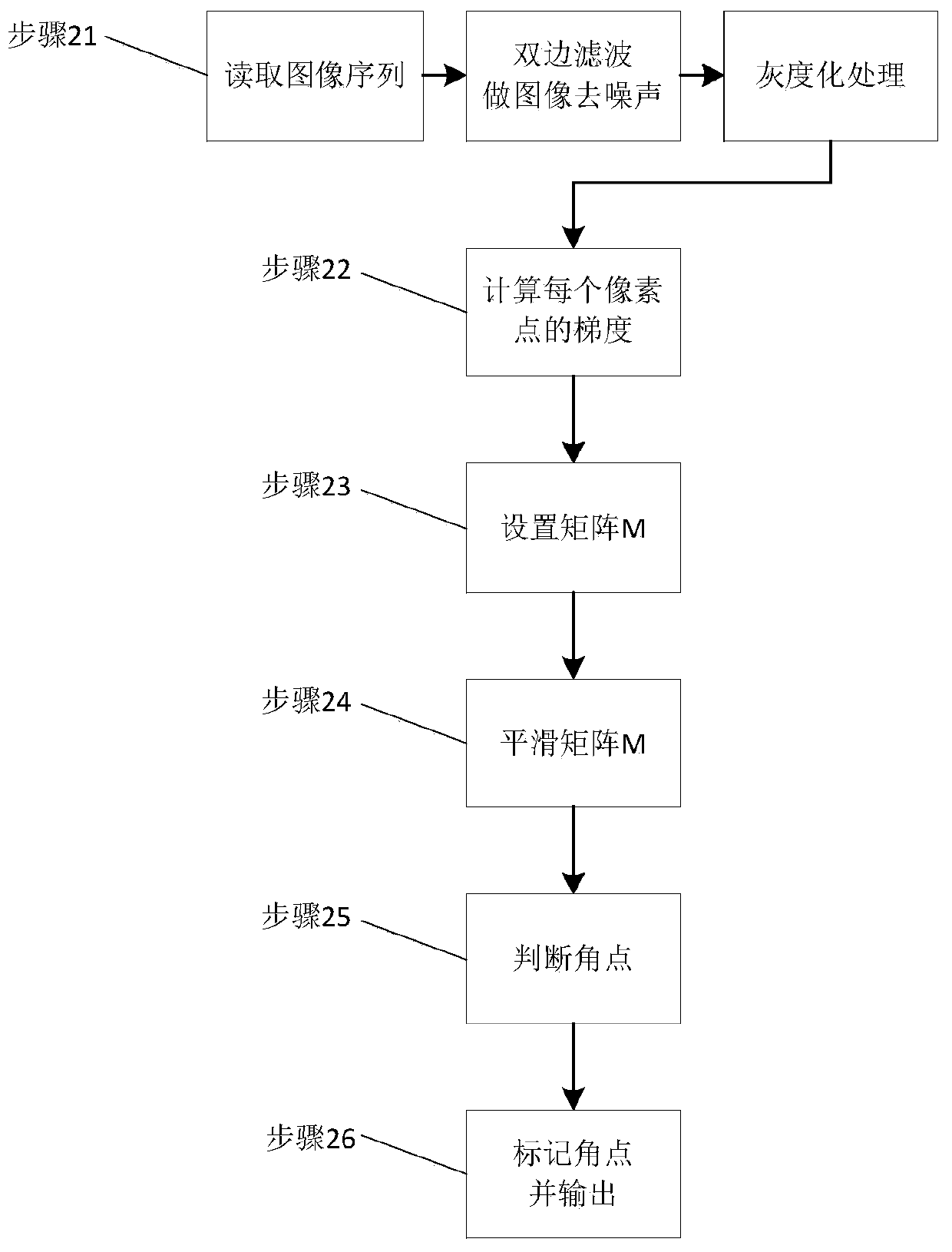

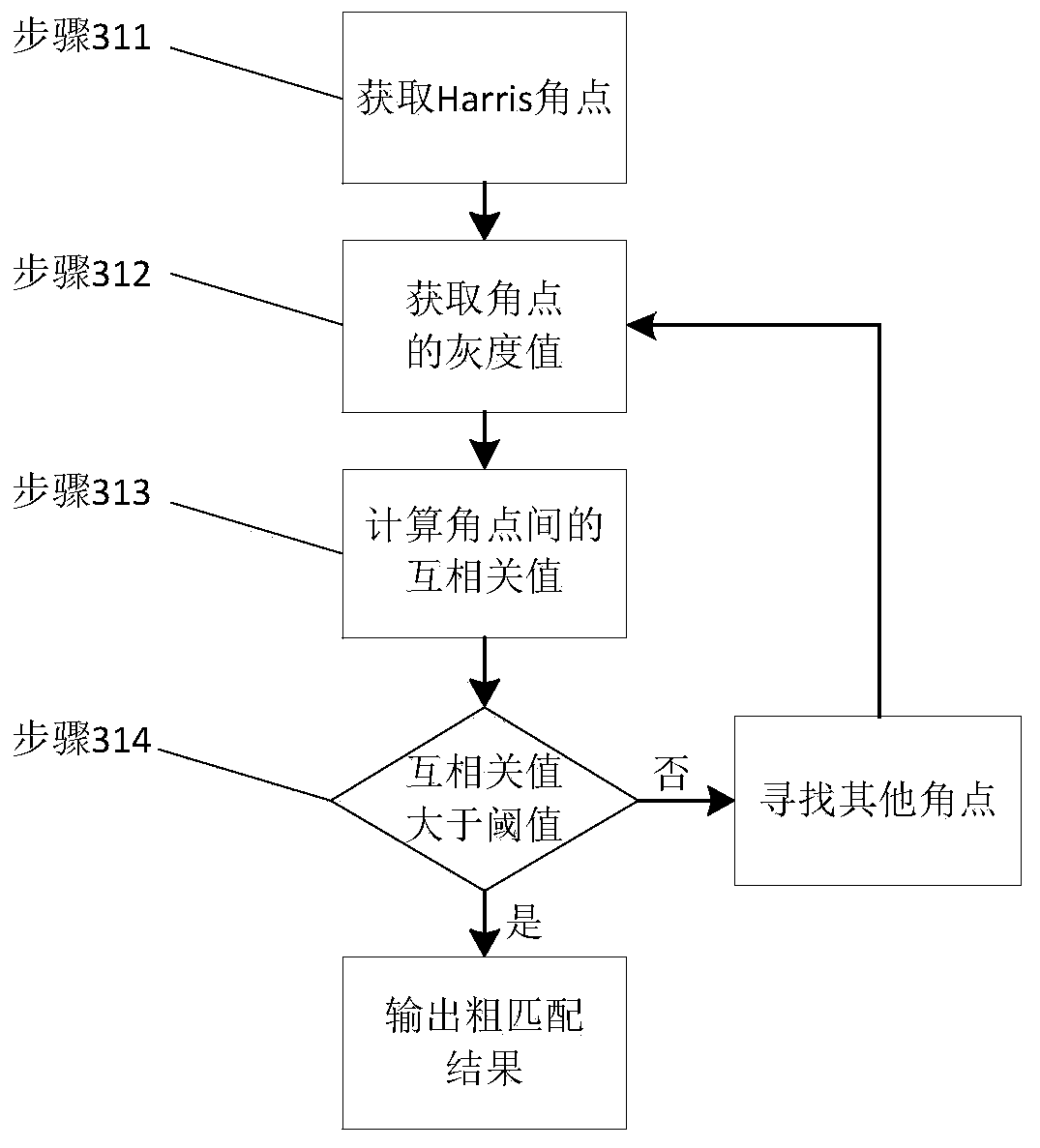

The invention relates to a building volume measurement method based on a UAV picture. The building volume measurement method based on the UAV picture comprises the steps of: performing surround picture information acquisition on a building by utilizing a UAV, and obtaining multiple picture sequences of the building; after the picture sequences are processed by bilateral filtering, obtaining cornerpoints of the picture sequences by adopting a Harris corner point detection algorithm; performing rough corner point matching by adopting a zero mean cross-correlation method, and establishing a one-to-many corresponding relationship; then, processing roughly matched corner points by adopting a relaxation iterative method, so that one-to-one precisely matched corner point pairs are obtained; circularly calculating space coordinates of matched points by utilizing a recovering structure algorithm from motion, and optimizing the space coordinates by utilizing a beam adjustment method, so that the three-dimensional point cloud of the building is obtained; performing Delaunay triangularization on the three-dimensional point cloud by utilizing a point-by-point insertion method; and finally, calculating the volume of the building on a constructed Delaunay triangular net model by utilizing an integral method.

Owner:NANJING UNIV OF POSTS & TELECOMM

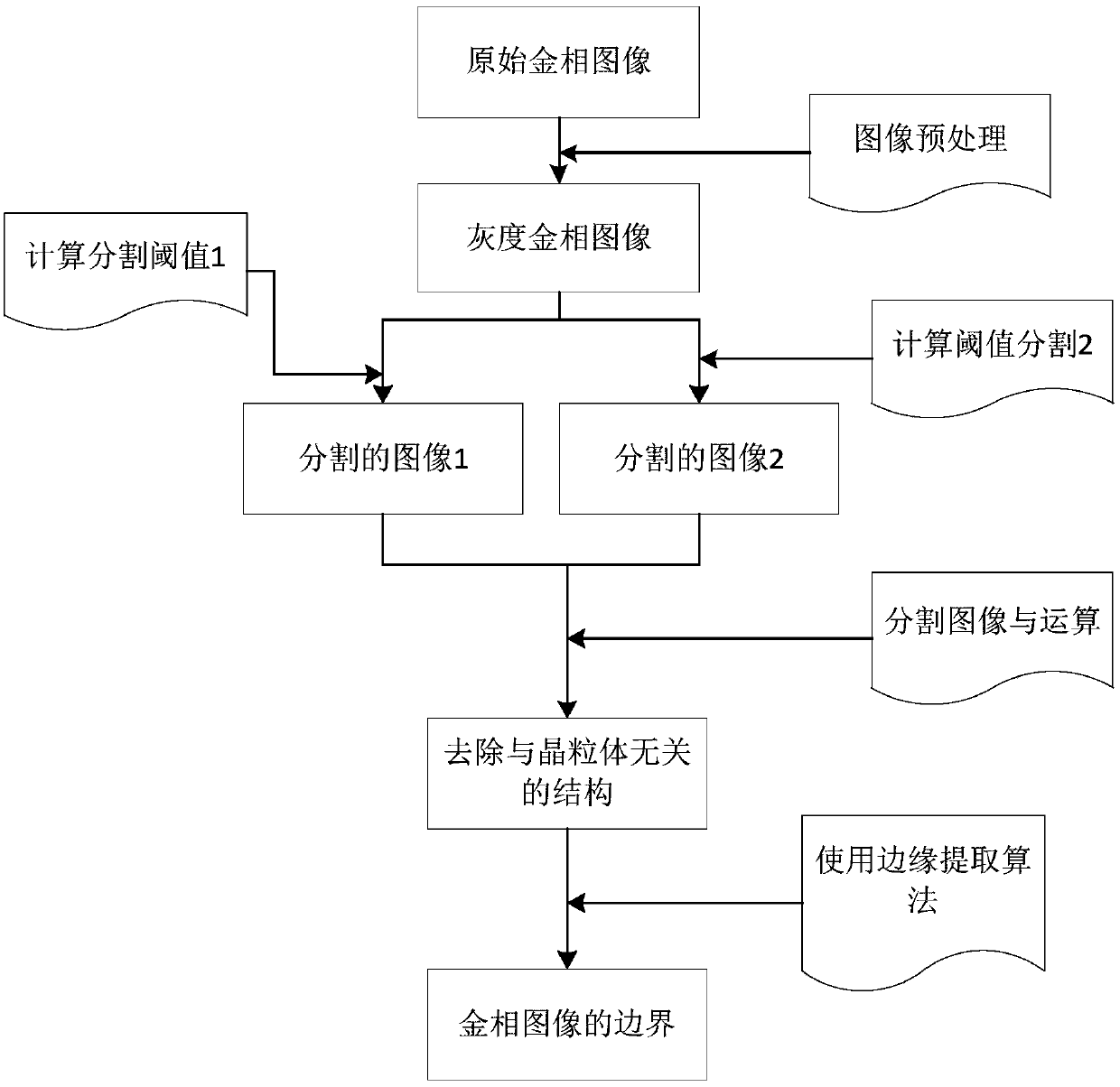

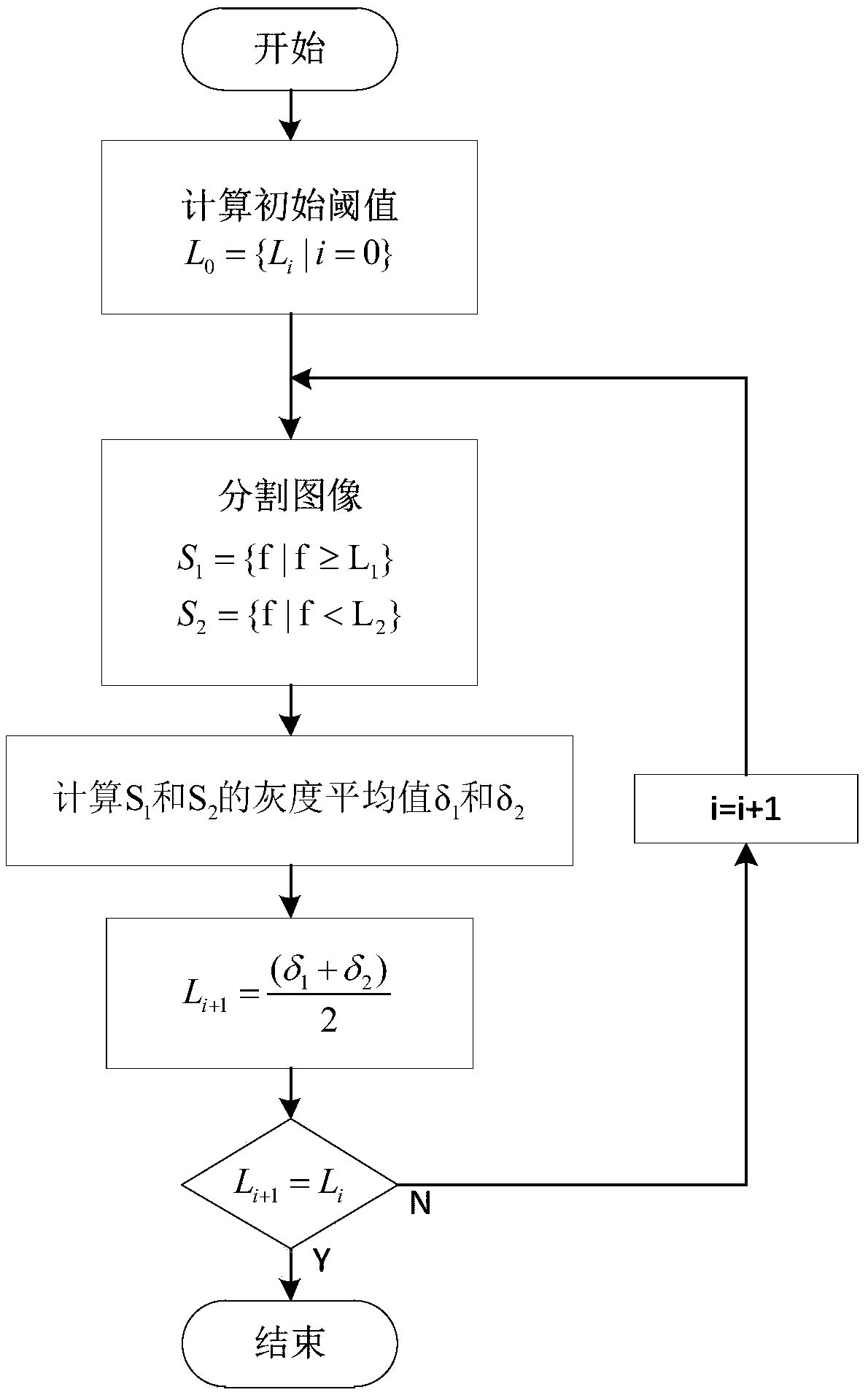

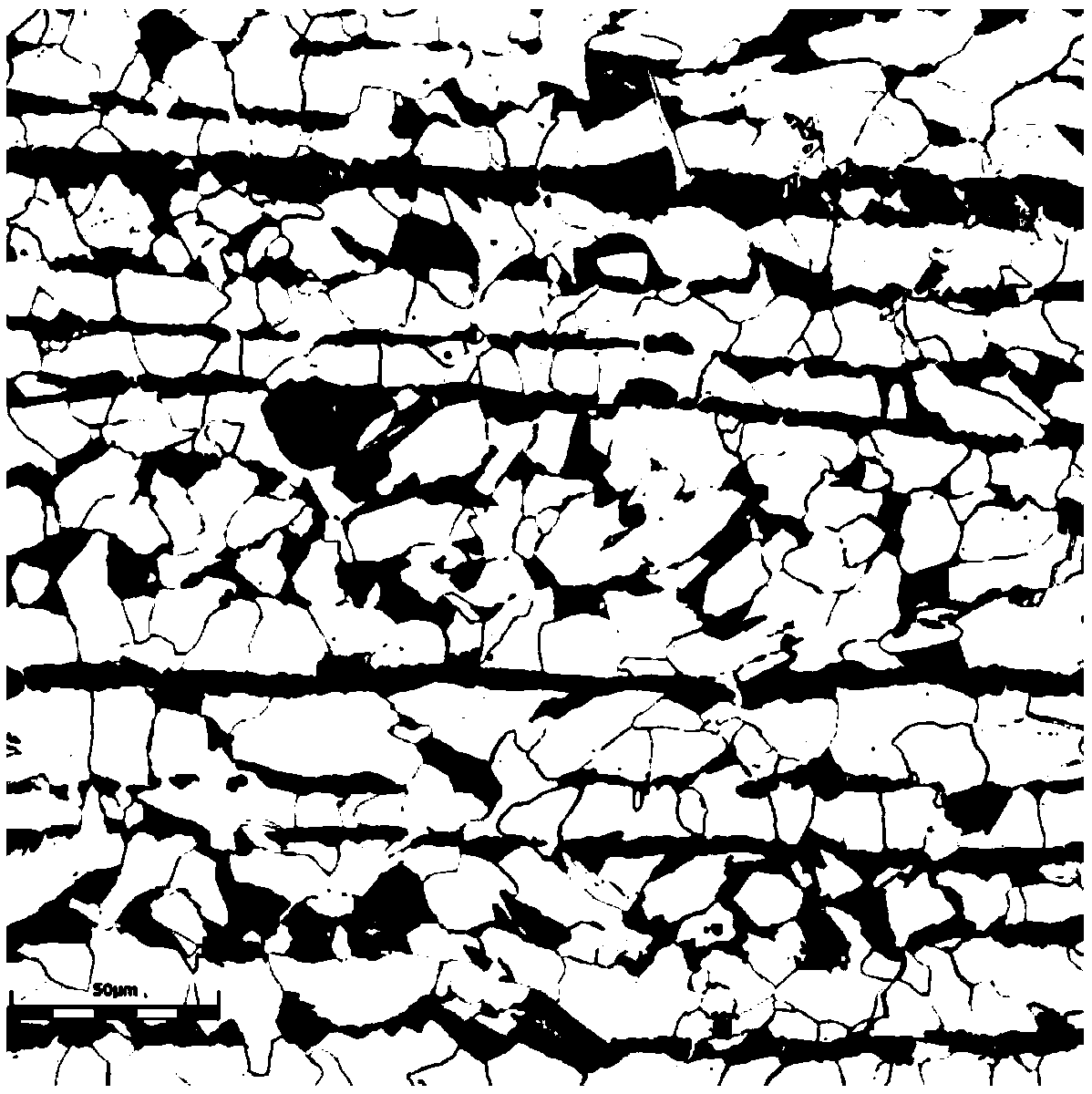

A metallographic image edge detection method based on mathematical morphology

PendingCN109544571AHEPAPrecise positioningImage enhancementImage analysisImage detectionImproved algorithm

The invention discloses a metallographic image edge detection method based on mathematical morphology. Firstly, the metallographic image is converted into a contrast-equalized gray-scale image to reduce noise and enhance edge information. Then the histogram of the image is computed, the histogram is normalized, the integrals of the histogram are computed, and the integrals of the histogram are used as a look-up table for image transformation. Secondly, two thresholds of segmented images are generated by a self-defined improved algorithm based on iterative method. The foreground image and background image of the image are segmented by the two thresholds respectively. NAND operation is performed on the two images to remove the grains-independent structures from the images. Finally, the edgeimage of the grain is obtained by the self-defined multi-scale and multi-structure algorithm. The invention reduces the boundaries of missed detection, multiple detection and false detection, the extracted edges have better continuity and smoothness, and the positioning of the boundaries is more accurate, and the characteristics of the metallographic images are fully considered, so that the pertinence is stronger.

Owner:NANJING UNIV OF SCI & TECH

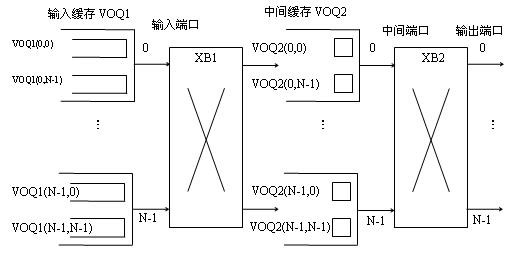

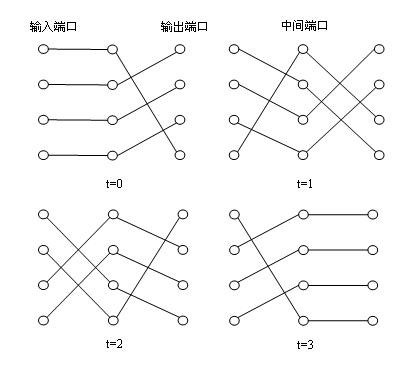

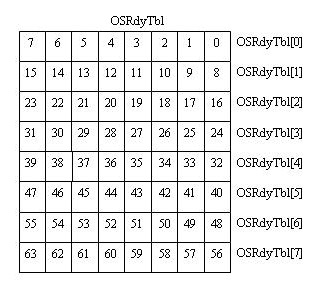

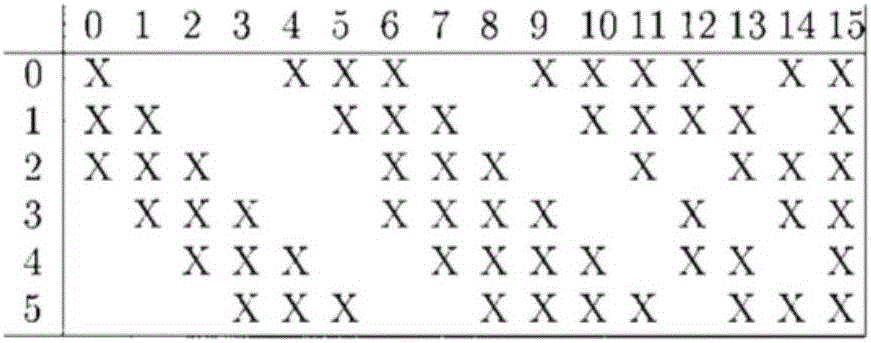

Dispatching algorithm suitable for feedback two-stage exchange structure

InactiveCN101945054AReduce complexityImprove high-speed switching capabilitiesData switching networksQueue numberRound complexity

The invention discloses dispatching algorithm suitable for feedback two-stage exchange structure, which is suitable for an optional input port i in a fiber-to-the-service-area (FTSA) structure to select a queue head cell of a non-nullVOQ1 (i,r) meeting the condition that a virtual output queue (VOQ)2 (j,r) is null according to the rules of the algorithm and sends the queue head cell to an intermediate port j connected with the input port i in a next time slot, wherein the first non-null VOQ1 (i, r) which meets the condition that VOQ2 (j,r) is null is searched according to a sequence of r= i-2, i-3,..., 0, N-1, N-2,..., i, i-1 and the queue head cell of the VOQ2 (j,r) is forwarded to the optional input port. The dispatching algorithm comprises the following steps of: establishing mapping; filtering information; dispatching priority bitmap algorithm; and finally, reversely mapping a dispatching result into sub-sequence number. The dispatching algorithm ensures that the algorithm complexity of the FTSA structure is reduced from O (N) to O (1) and improves the high-rate exchange capability and expandability of the FTSA.

Owner:SOUTHWEST JIAOTONG UNIV

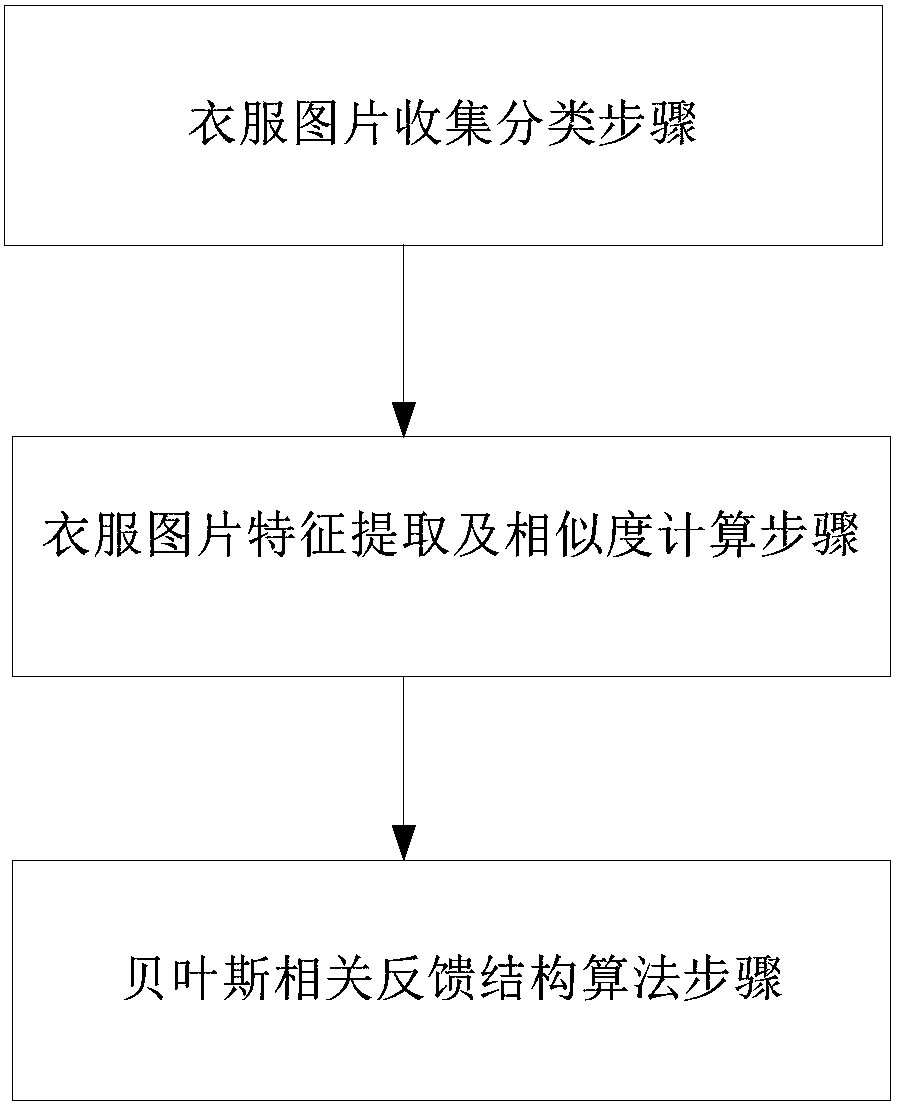

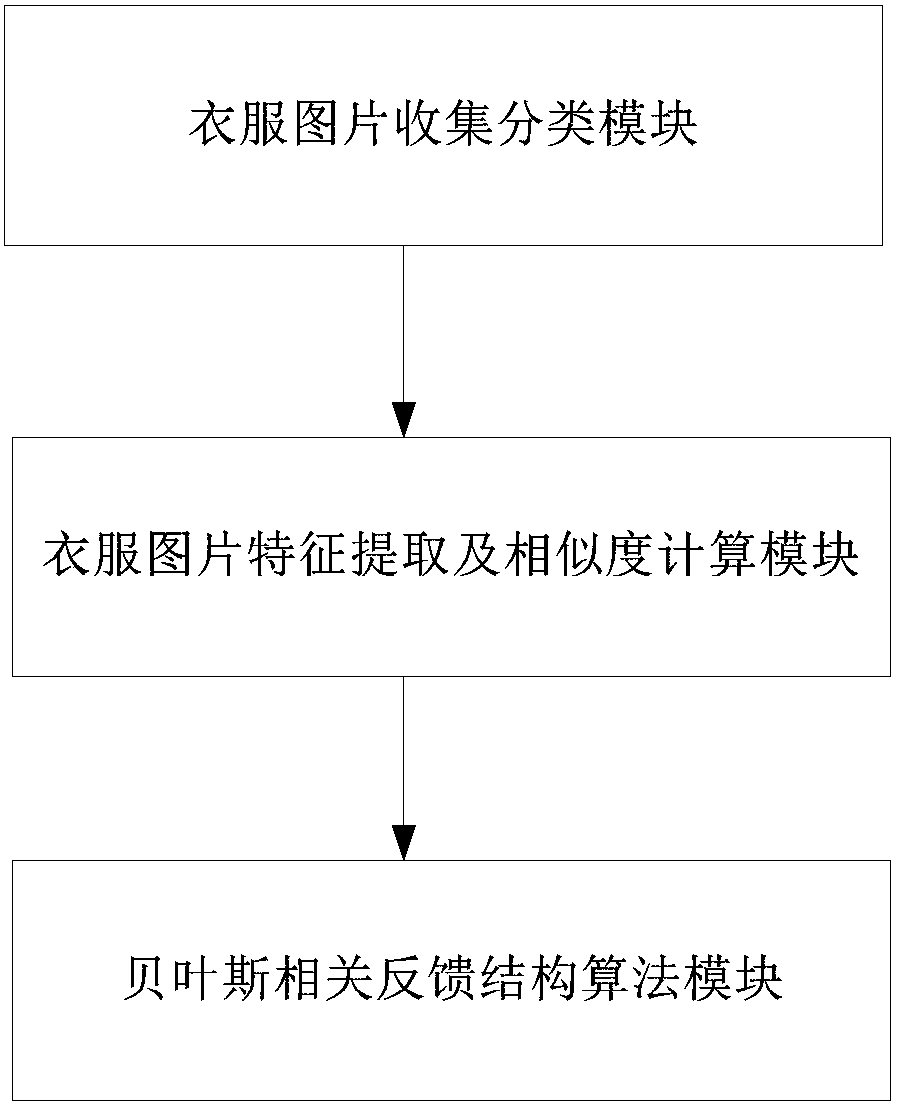

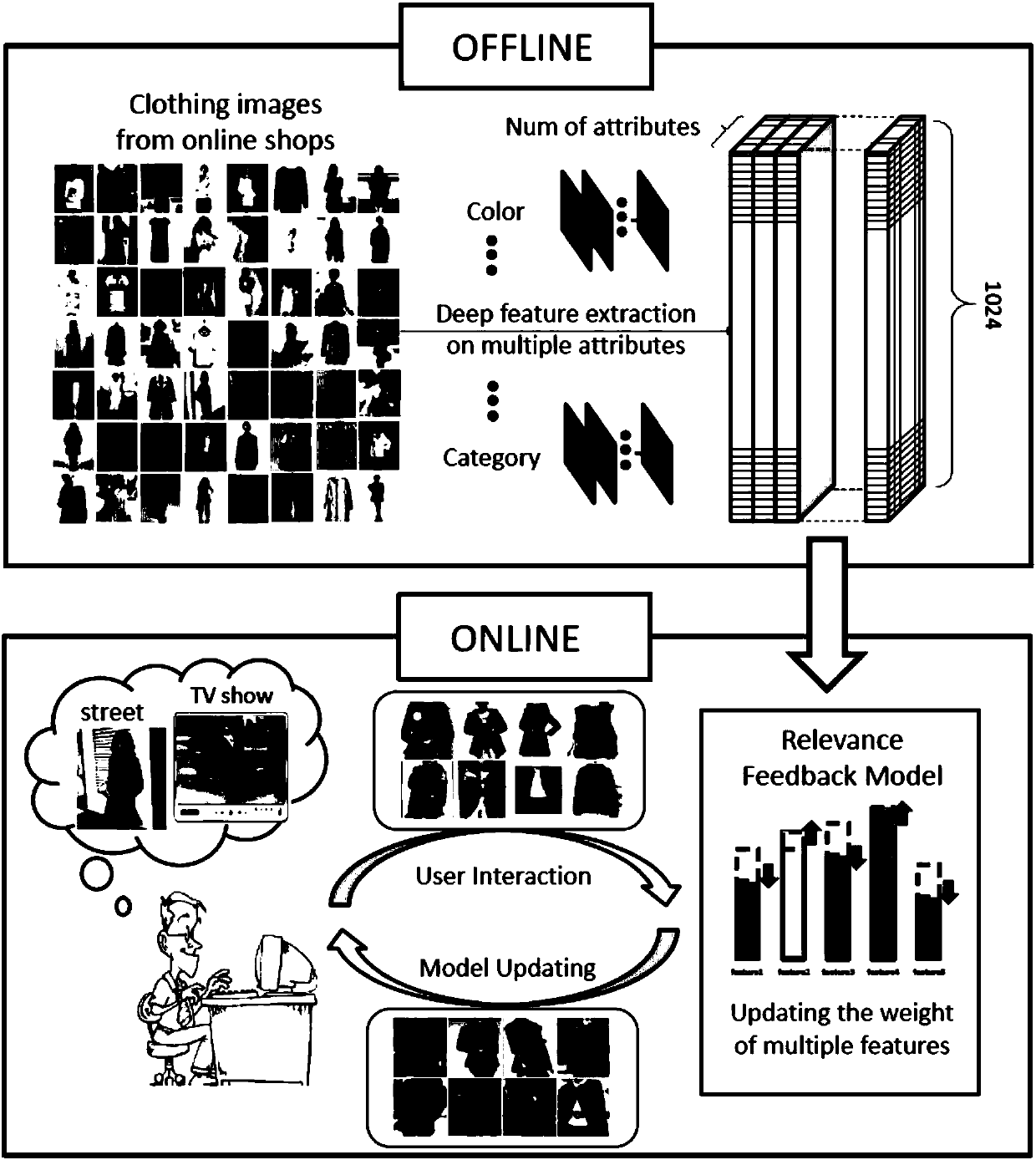

Garment image retrieval system and method through indirect relevance feedback without checking source

The present invention provides a garment image retrieval system and method through indirect relevance feedback without a checking source. The method comprises: obtaining a large number of garment pictures and clustering the garment pictures according to the types and colors; for each picture collected by a garment picture collection module, according to multiple features selected in the type, extracting a vector with a fixed length by using a deep neural network, and according to each feature, calculating the similarity between the pictures; and according to the similarity between pictures obtained in the garment picture feature extraction and similarity calculation step, through the Bayesian feedback structure algorithm, after the user clicks a picture most similar to a target picture ateach time, adjusting the weight of the selected features, then returning the weight to the user recommended garment picture, and finding out the target picture of the user through iteration. The system and method provided by the present invention solve the problem that a user cannot find out a target garment picture under the condition that there is no checking source of the garment pictures and only basic types and colors can be given out.

Owner:上海媒智科技有限公司

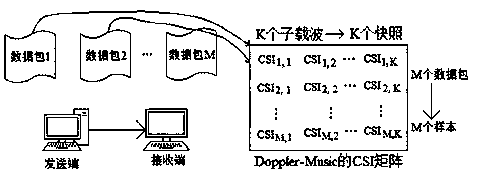

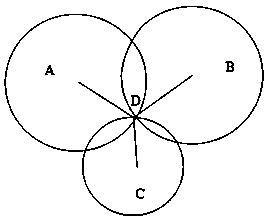

Personnel trajectory tracking method based on CSI (Channel State Information)

ActiveCN108882171AReduce kinetic energy fluctuationsParticular environment based servicesLocation information based serviceChannel state informationDoppler velocity

The invention provides a personnel trajectory tracking method based on CSI (Channel State Information). CSI signal values are extracted. A position of the maximum value of a spectrum function represents the highest point of an image. Element carrier frequency and propagation velocity of signals are known, so Doppler velocity can be obtained. Redundant point removal is carried out on obtained active points through adoption of a smoothing algorithm. Positions of the active points are determined through utilization of an improved trilateral positioning algorithm based on the least square method.Whether a structure algorithm is in a reference range or not is judged. If the structure algorithm is in the reference range, the obtained points in an active range are processed. Enough points are collected for simulation of trajectories of personnel in a room. According to the trajectory tracking method, all active points of the indoor personnel are drawn into a trajectory image and are visuallydisplayed, and the relatively accurate tracking and positioning of the indoor personnel is realized.

Owner:NORTHWEST NORMAL UNIVERSITY

Online interactive visualization method for precision assurance of global geospatial data

InactiveCN109255004ATroubleshoot performance issues with processingFix performance issuesGeographical information databasesImage resolutionRelational database

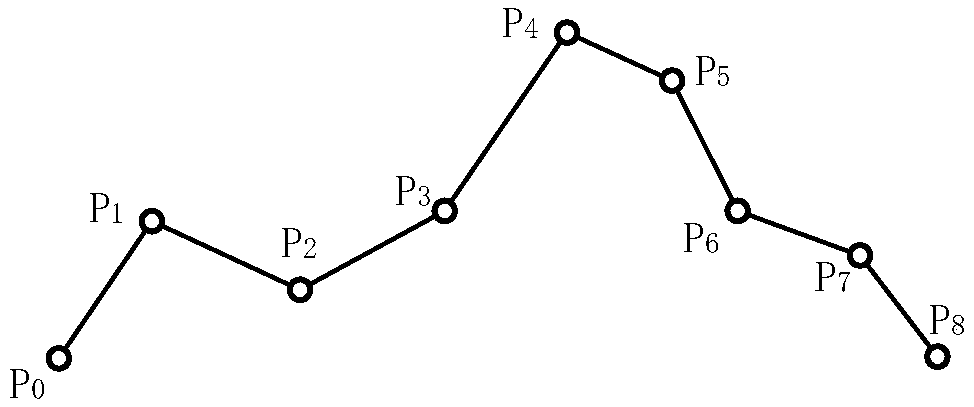

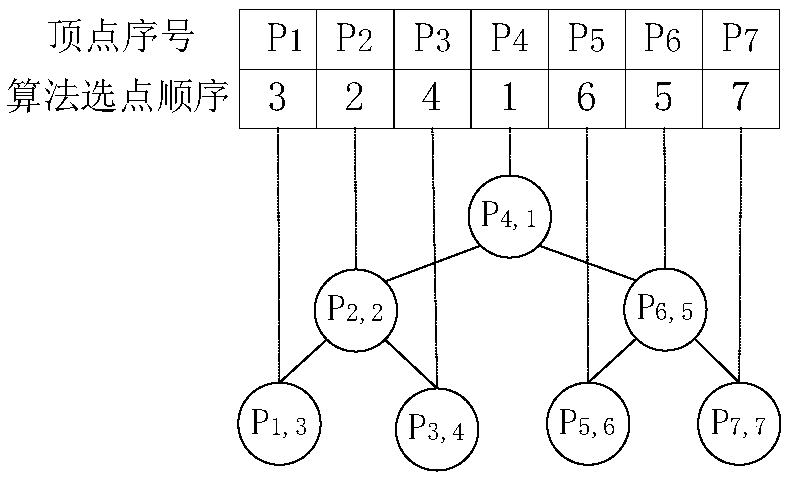

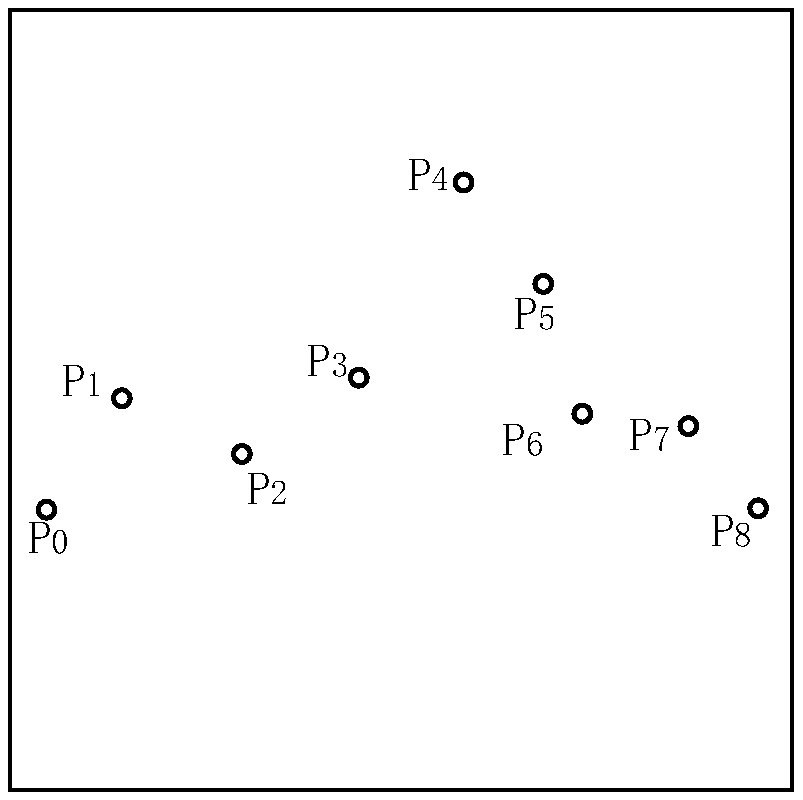

An online interactive visualization method for precision assurance of global geospatial data comprises the following steps: a multi-resolution hierarchical structure algorithm construction step of geographic elements, a vertex spatial index structure construction step, a spatial approximate query processing step based on a relational database and a query result visualization step. The invention provides an approximate calculation idea to solve the performance problem of geospatial big data processing, and on the basis of multi-resolution expression of geospatial elements and according to queryconditions, an approximate element capable of representing the original element with controllable error is generated. Geographical elements are expressed by spatial approximate query results, that is, elements are generated by vertex sampling in real time and approximate errors are reported to achieve flexible control of query precision and time.

Owner:CHINESE ACAD OF SURVEYING & MAPPING

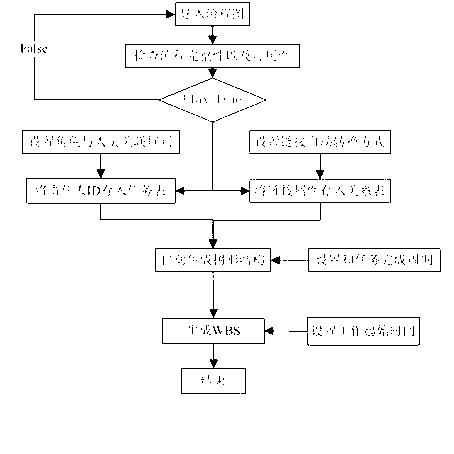

Work breakdown structure (WBS) automatic generation method based on flow diagram

InactiveCN103136246AReduce redundancyGuaranteed accuracySpecial data processing applicationsWork periodAutomatic Generation Control

The invention relates to a work breakdown structure (WBS) automatic generation method based on a flow diagram. The method comprises a first step of automatically generating a tree structure and a set membership between activity instances by leading the flow diagram in and setting an interlinkage automatic conversion method, a second step of setting a task execution cycle, a third step of setting procedure start time, a fourth step of automatically calculating working time according to the procedure start time and the task execution cycle, a fifth step of enabling workflow and a task tree to share a basic information table, and data bank redundancy is reduced. Value field range can be reduced by setting of the interlinkage conversion method, the tree structure algorithm is automatically generated, the problem of a constrained relationship among tasks is well solved, and efficiency is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

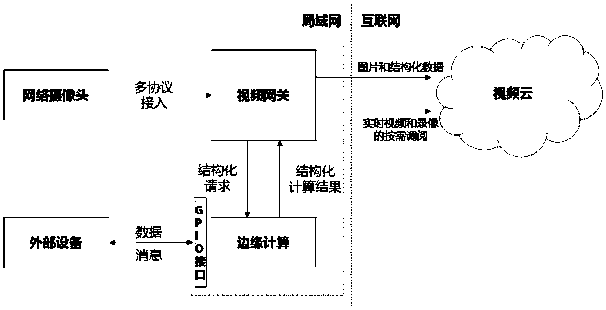

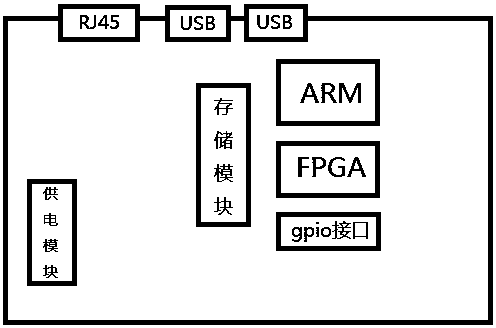

Device integrating Internet video access gateway and edge computing

InactiveCN108111821ALow costEasy maintenanceTelevision system detailsColor television detailsEdge computingMonitor equipment

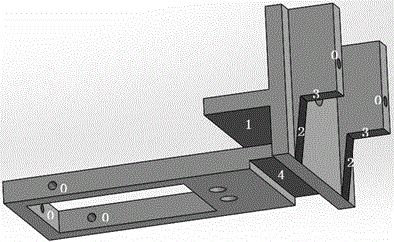

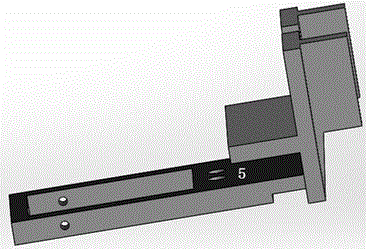

The invention provides a device integrating an Internet video access gateway and edge computing. The device comprises a shell (1) for packaging internal components, an ARM+FPGA motherboard (2) with agpio interface, a power supply device (3), a video structured algorithm (4), an Internet video access gateway solution (5), a plurality of auxiliary components and parts and driving programs of related devices. The ARM+FPGA motherboard (2) with the gpio interface is used as a computing platform and is provided with the Internet video access gateway solution (5) and the video structured algorithm (4) therein, the invention provides an overall management solution in which the device is accessed to a local area network where a traditional monitoring device is located, the monitoring device information and video streams are automatically grabbed through "onvif, GB / T28181", as well as proprietary protocol scanning of a mainstream camera device in the market, and structuralization and intelligent push are implemented. Compared with the traditional structured computing platform using X86+ GPU as the hardware foundation, the device has the advantages of low cost and easy maintenance. Meanwhile, as the functions of the Internet video access gateway are integrated, the traditional monitoring devices that have been massively applied access the video cloud on the Internet more cheaply and securely, and the advantages of edge computing and low cost maintenance brought by the invention can also be enjoyed.

Owner:深圳羚羊极速科技有限公司

False information early detection method based on text structure algorithm

ActiveCN112699662AIncrease authenticityLoss minimizationSemantic analysisNeural architecturesPattern recognitionDocument representation

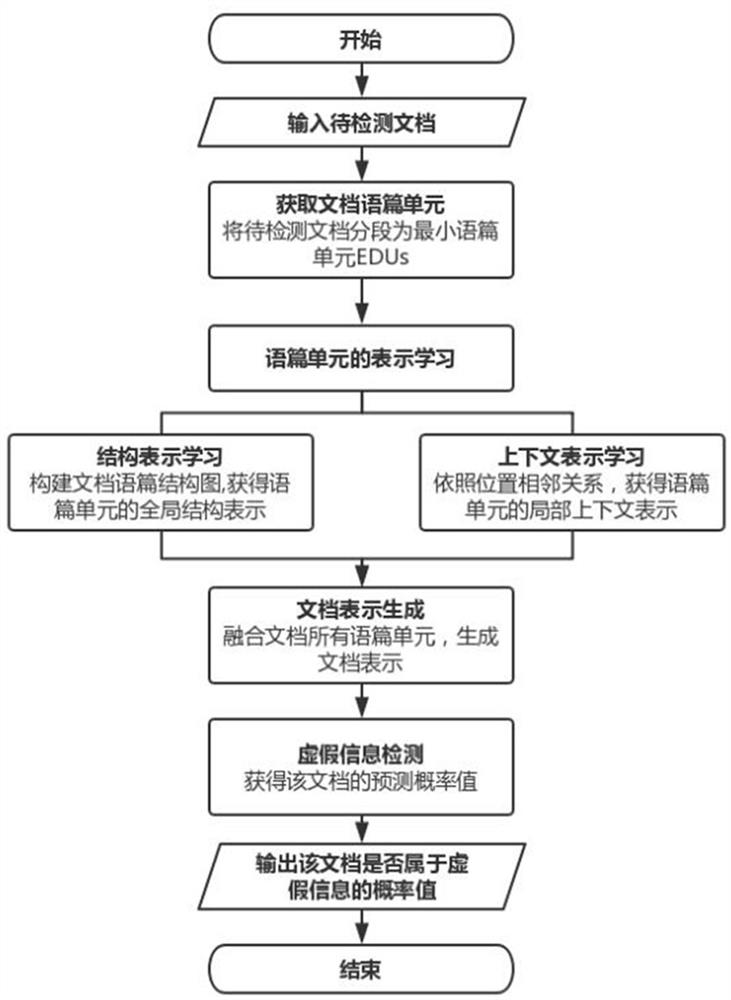

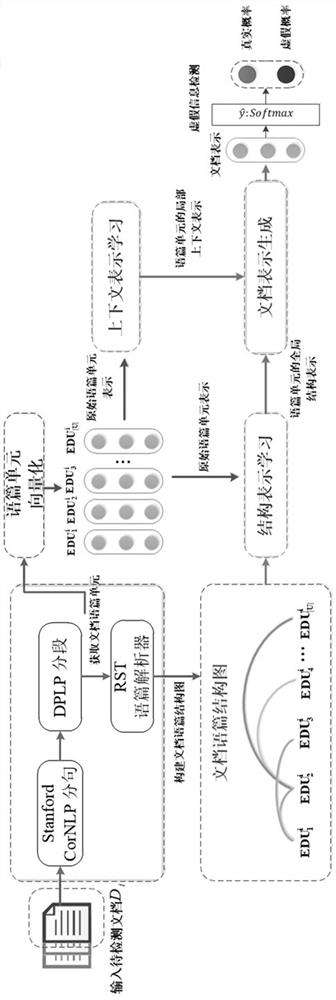

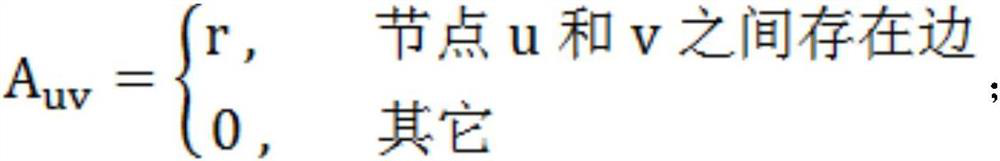

The invention discloses a false information early detection method based on a text structure algorithm, and belongs to the technical field of false information detection based on the text structure algorithm. The technical problem to be solved is to provide an improvement of a false information early detection method based on a text structure algorithm. According to the technical scheme, the method comprises the steps of document discourse unit obtaining, discourse unit representation learning and structure representation learning, a document discourse structure chart is constructed on the basis of a rhetortic structure theory, and global structure representation of discourse units is obtained through a multi-relational graph neural network; in context representation learning, the position adjacent relation of discourse units in a document serves as a calculation object, local context representations of the discourse units are obtained, all the discourse units of the document are fused to form document representations based on a gating recursion unit fused with a global attention mechanism, the generated document representations are used for false information detection, and a probability value of whether the input document belongs to false information or not is obtained. The method is applied to false information detection.

Owner:TAIYUAN UNIV OF TECH

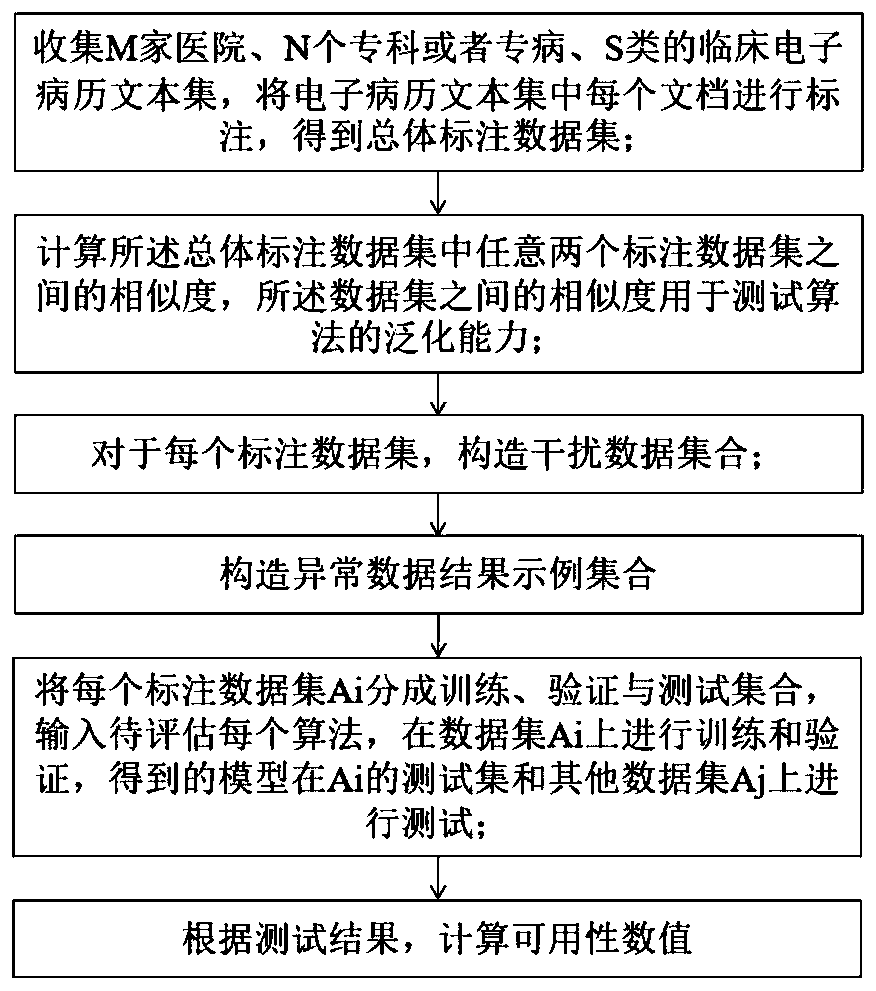

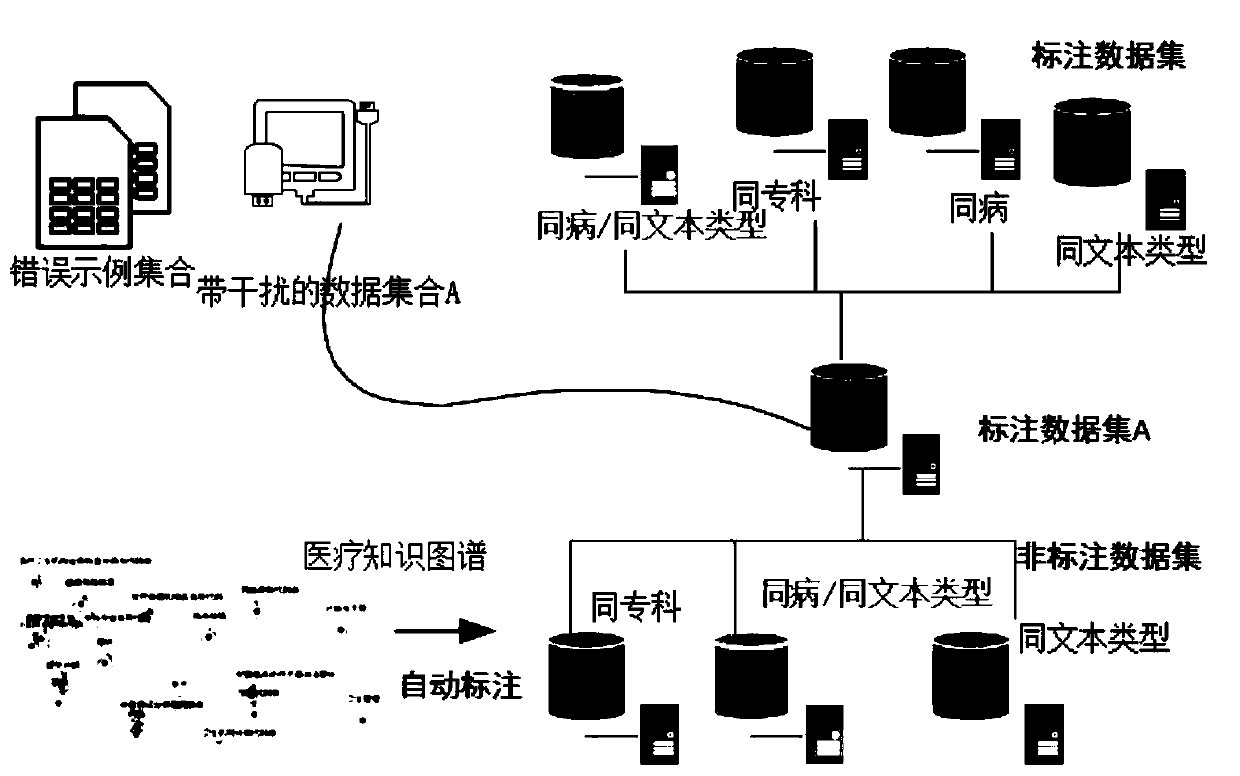

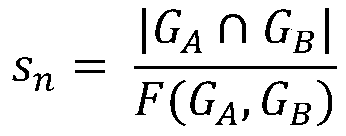

Availability evaluation method for medical text structuring algorithm

The invention provides a novel availability evaluation method for a medical text structuring algorithm. For any medical text structuralization algorithm, the availability is used for evaluating the medical text structuralization algorithm, and the numerical value proves that the algorithm is suitable for practical application scenes to a large extent and comprises three dimensions: generalizationability on corpora of different hospitals and different departments; the anti-interference capability of the algorithm is improved; and the tolerance of algorithm errors is improved. Based on the definition of availability, a specific available evaluation method is constructed in combination with the similarity relationship between medical texts, the type of algorithm errors, the type of data interference and the like. Indexes and methods investigate whether medical text-oriented machine learning algorithm theoretical research is suitable for practical application scenarios or not, and can also be used in other fields.

Owner:EAST CHINA UNIV OF SCI & TECH

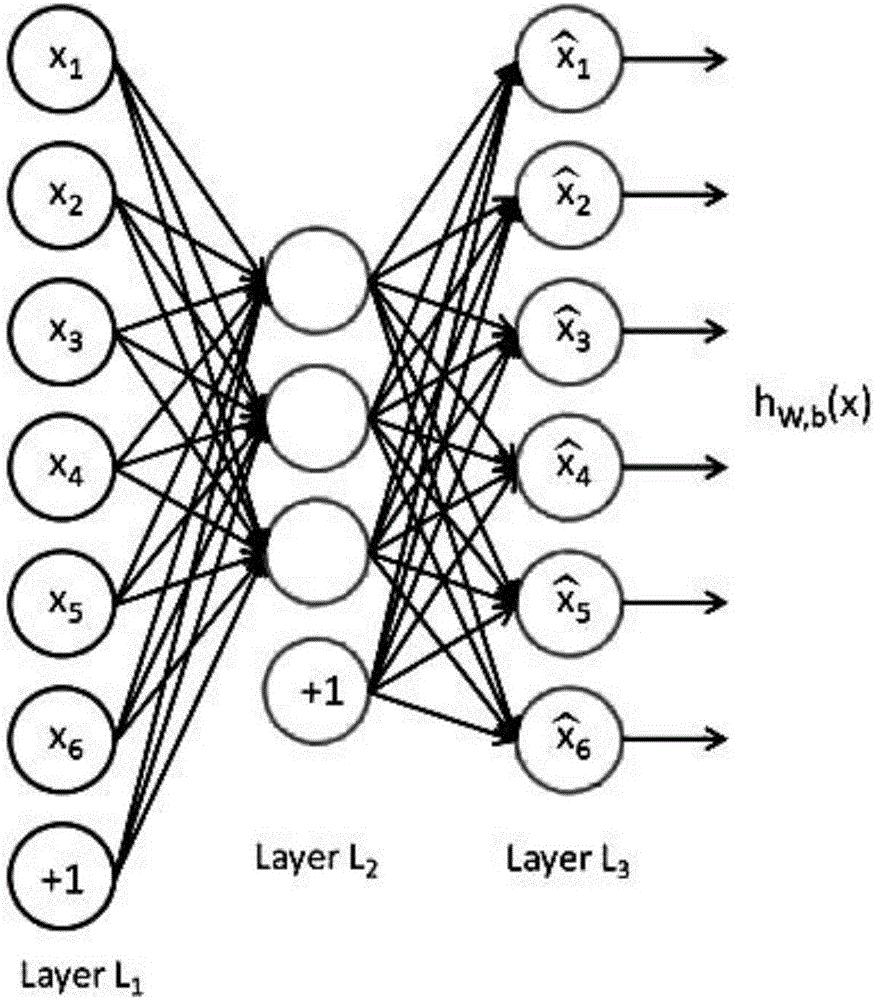

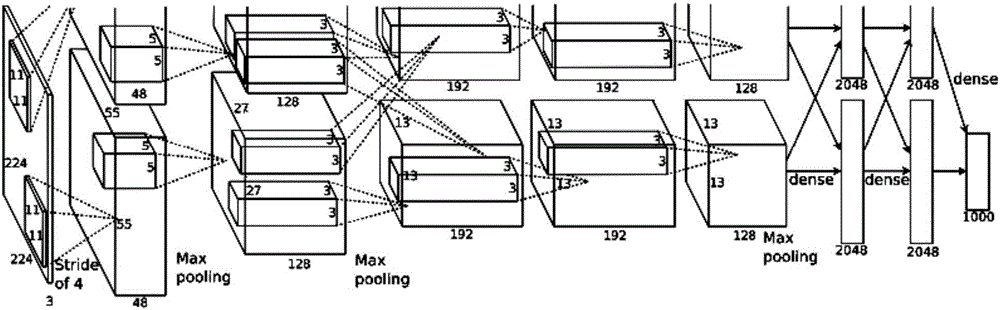

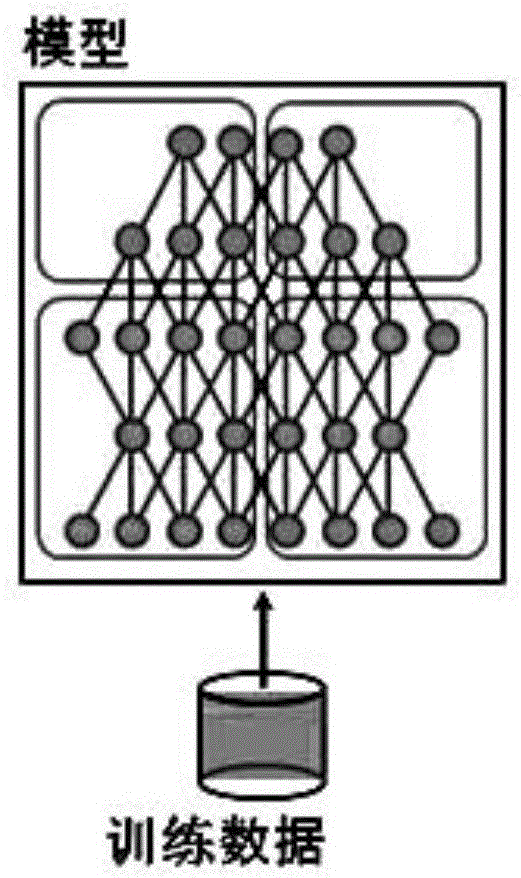

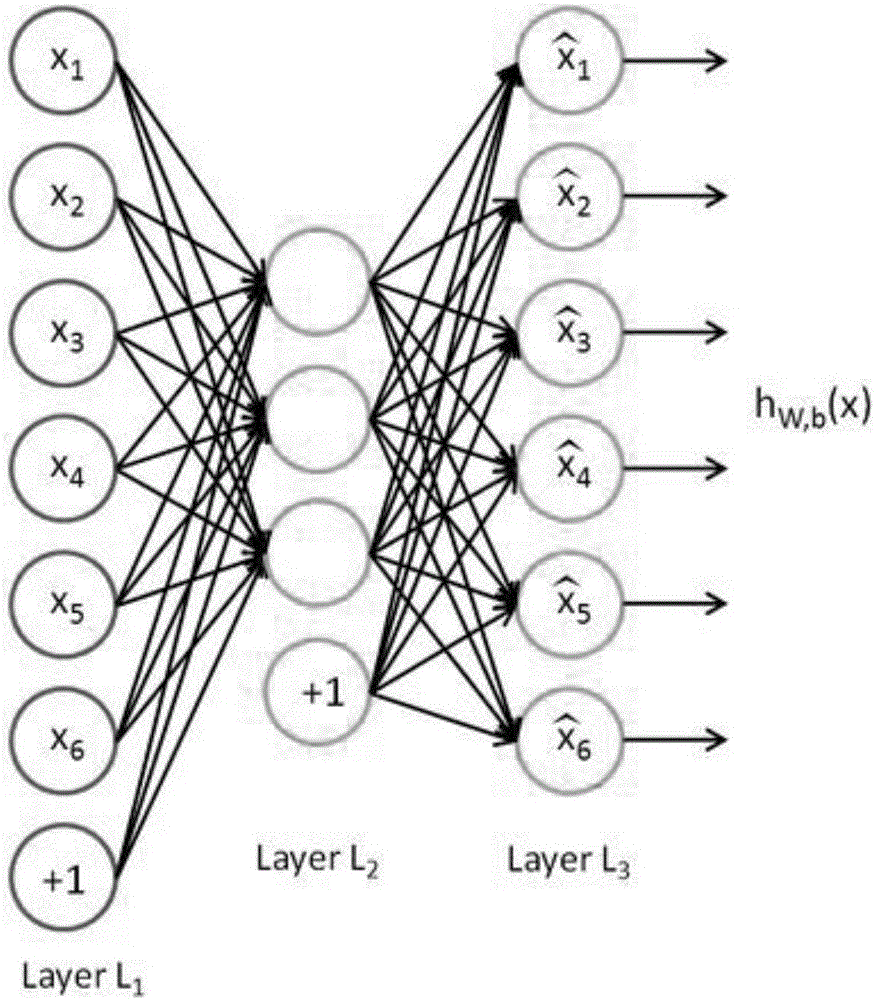

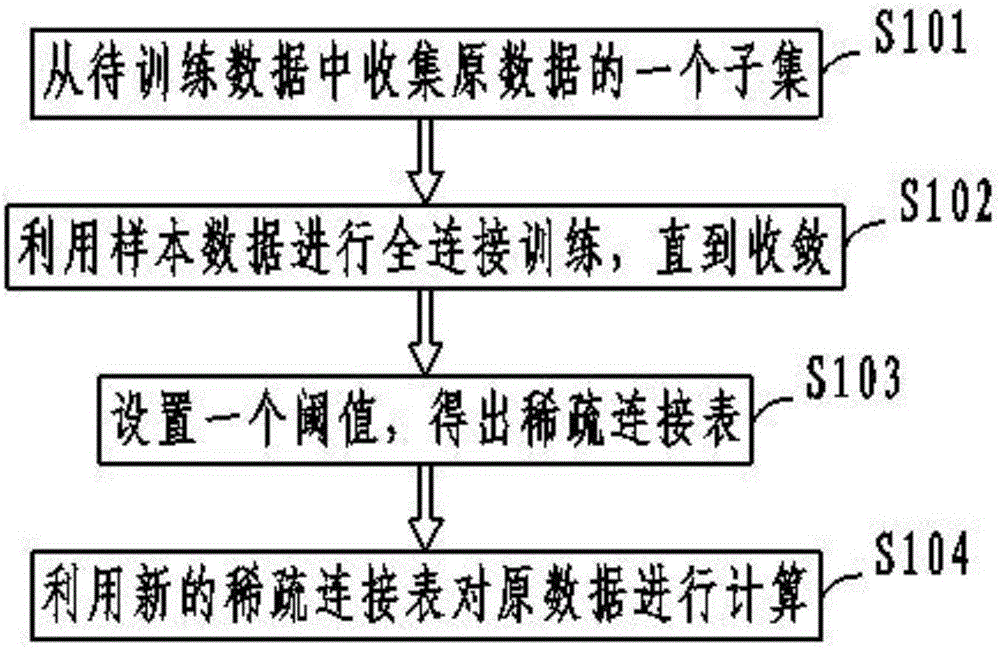

Local connection communication based deep learning network structure algorithm

InactiveCN106845637AImprove scalabilitySmall amount of calculationNeural learning methodsComputational problemNetwork connection

The invention relates to the technical field of deep learning network structure algorithms, in particular to a deep learning network structure algorithm based on local connection communication; The deep learning network structure algorithm is based on the deep learning network structure algorithm; the adopted technical solution is: comprising the following steps: S101, determining a network connection model between each network layer according to a computing problem; S102, allocating each network layer to each computing node according to a parallel processing method S103, determine the communication relationship between each computing node; S104, keep the communication between adjacent nodes, for the communication across nodes, delete directly; S105, generate new model according to the connection relationship after the deletion operation in step S104; S106, using the new model to perform parallel computing; the present invention is applicable to the field of deep learning algorithms.

Owner:DAWNING INFORMATION IND BEIJING

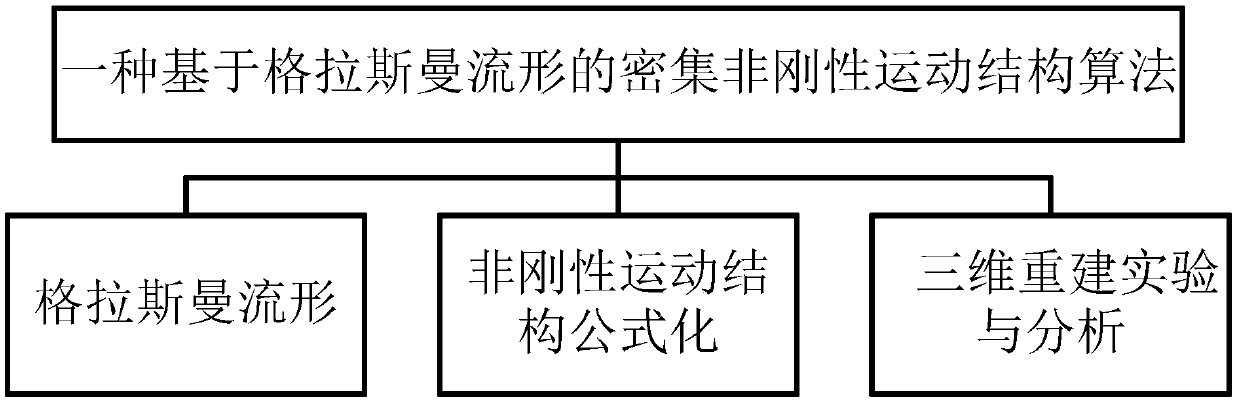

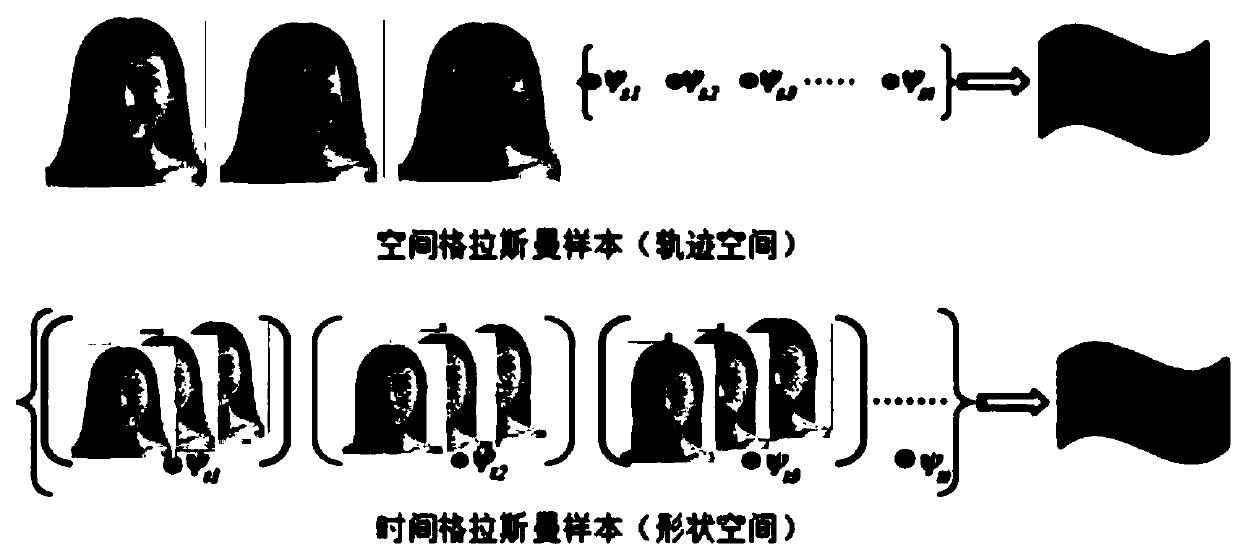

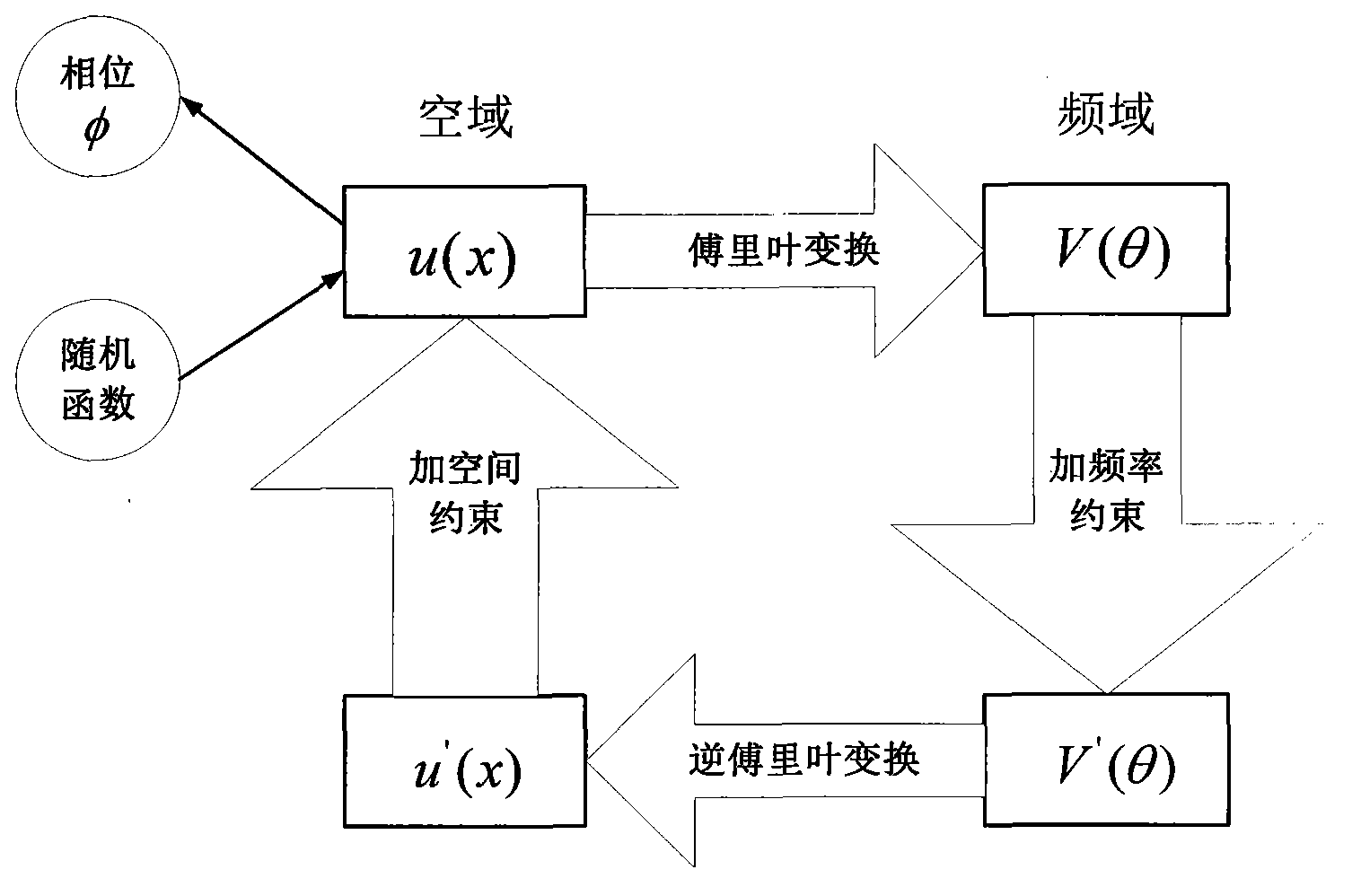

Dense non-rigid motion structure algorithm based on Grassmann manifold

InactiveCN108805974ANon-convex problem solvingSpecial data processing applications3D modellingData setNonlinear deformation

The invention provides a dense non-rigid motion structure algorithm based on a Grassmann manifold. The main content of the algorithm comprises Grassmann manifold construction, non-rigid motion structure formulation and three-dimensional reconstruction experiment and analysis. According to the process of the algorithm, first, Grassmann formulation representation is performed on a track space; second, Grassmann formulation representation is performed on a shape space; third, spatial-temporal formulation is performed, and bilinear optimization is performed; and last, a three-dimensional reconstruction experiment is performed, and control variable analysis and runtime analysis are performed. According to the algorithm, when a non-rigid motion structure is processed based on the Grassmann manifold, no prior template is needed, non-linear deformation with noise can be processed, and a final result based on a basic dataset can be provided; and the algorithm has better data extensibility and higher reconstruction precision, and comprehensive performance is optimal.

Owner:SHENZHEN WEITESHI TECH

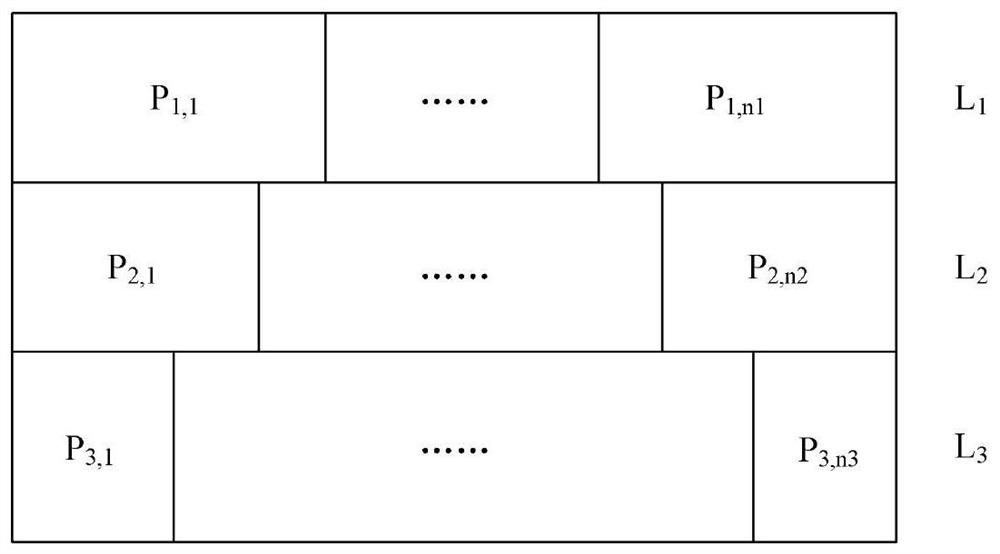

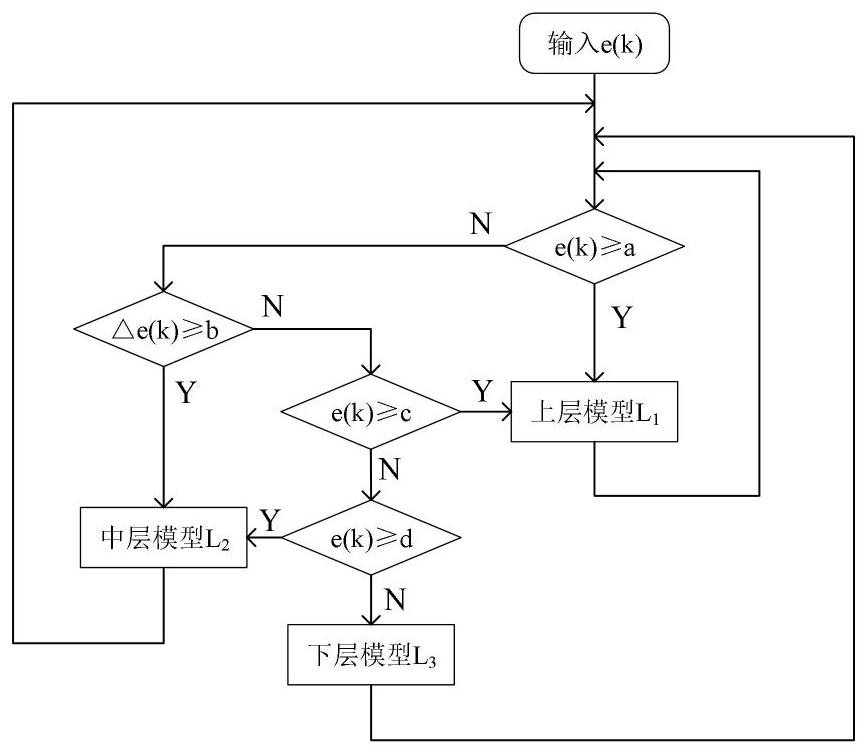

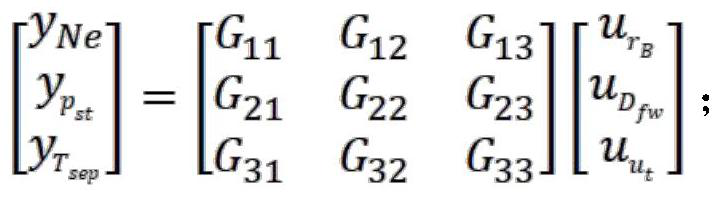

Supercritical unit coordination control method based on hierarchical model predictive control algorithm

PendingCN112526882AAdapt to different control objectivesGuaranteed Coordinated Control PerformanceAdaptive controlSteam pressureLayered model

The invention discloses a supercritical unit coordination control method based on a hierarchical model predictive control algorithm. The method comprises the following steps: regarging a controlled object of a supercritical unit as a three-input three-output multivariable system, the input quantity of the system being a water supply flow, a steam turbine control valve opening and an actual coal asfired quantity, and the output quantity being the actual power of the unit, the machine side main steam pressure and the separator outlet temperature; expressing sub-models of different working conditions of the controlled object of the supercritical unit according to a CARIMA model, solving a model prediction value based on a diophantine equation, and finally solving a current optimal control quantity by taking the minimum performance index function as an optimization target; establishing a three-layer sub-model set by adopting a hierarchical structure algorithm; and according to the unit operation load range, the control deviation and the deviation change rate, combining different levels and different numbers of sub-model sets so as to adapt to different control targets during unit operation. The control effect of the supercritical unit can be effectively guaranteed, and the actual engineering requirement is met.

Owner:CPI NORTHEAST POWER +2

Method for solving CFD through structural/non-structural coupling

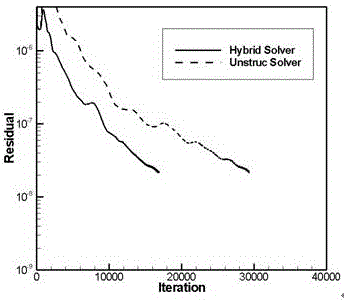

InactiveCN106096190AOvercoming the problem of losing the advantages of structural algorithmsUse flexibilityDesign optimisation/simulationSpecial data processing applicationsStructure algorithmStructural coupling

The invention discloses a method for solving CFD through structural / non-structural coupling. The method for solving CFD through structural / non-structural coupling includes the following steps that S1, a structural / non-structural hybrid grid is generated; S2, the hybrid grid is partitioned according to the efficiency of a structural resolver and a non-structural resolver; S3, the structural resolver and the non-structural resolver are called for CFD calculation. According to the method, when CFD is solved based on the hybrid grid, the problem that structural algorithm advantages can be lost in an existing method is solved, the flexibility of a non-structural grid can be exerted, and the advantages of high efficiency and high precision of a structural grid can be fully exerted.

Owner:赫新

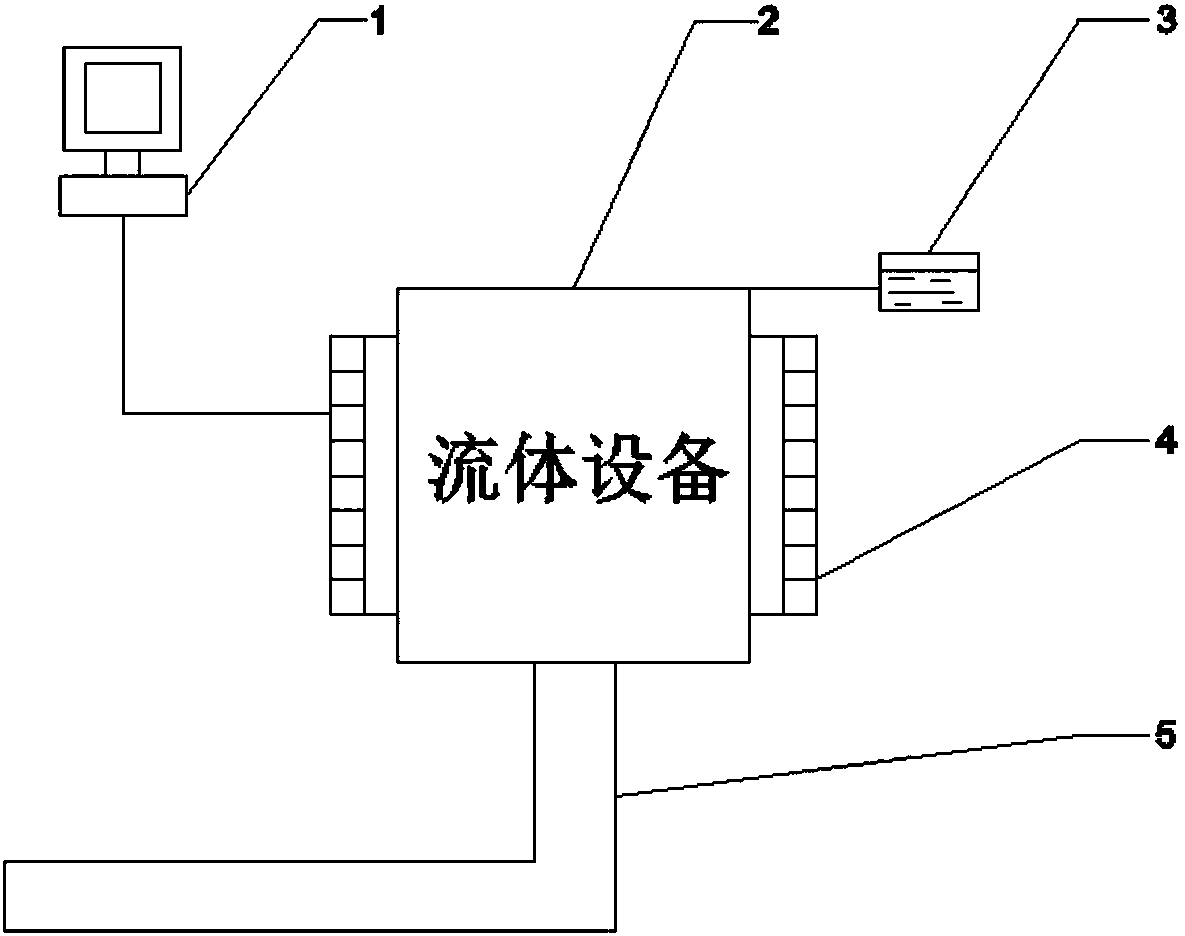

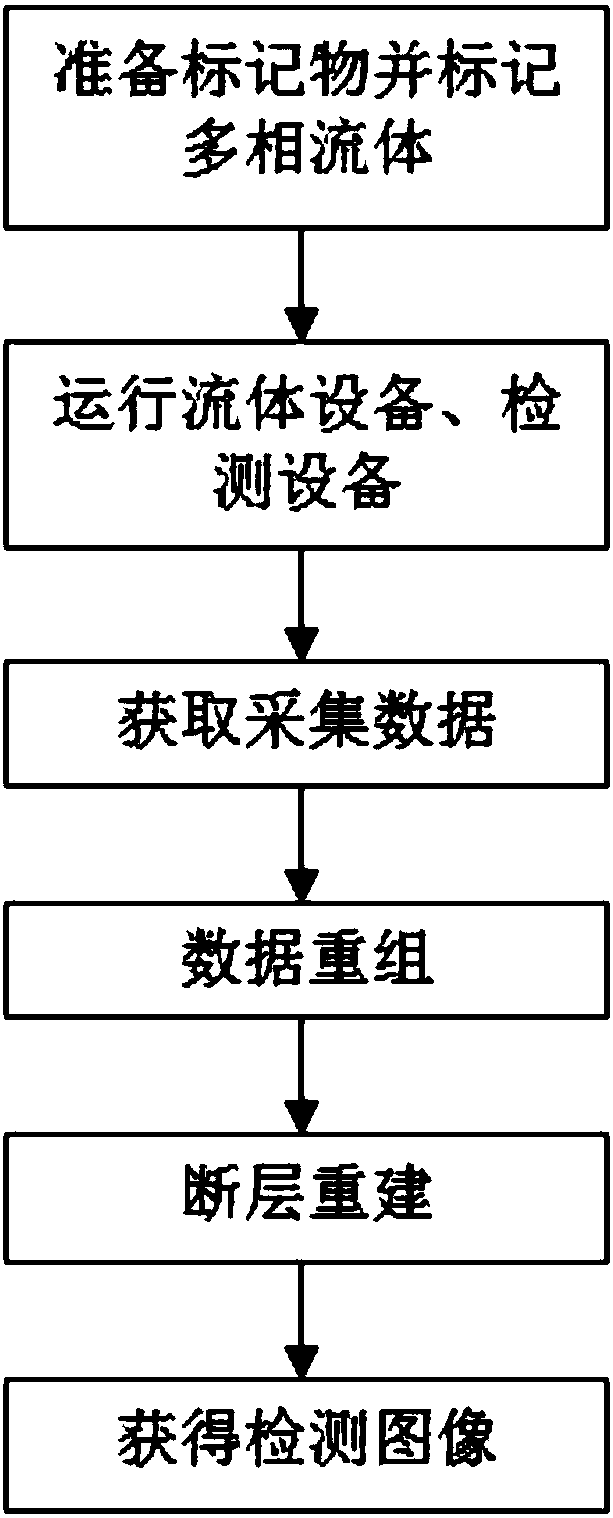

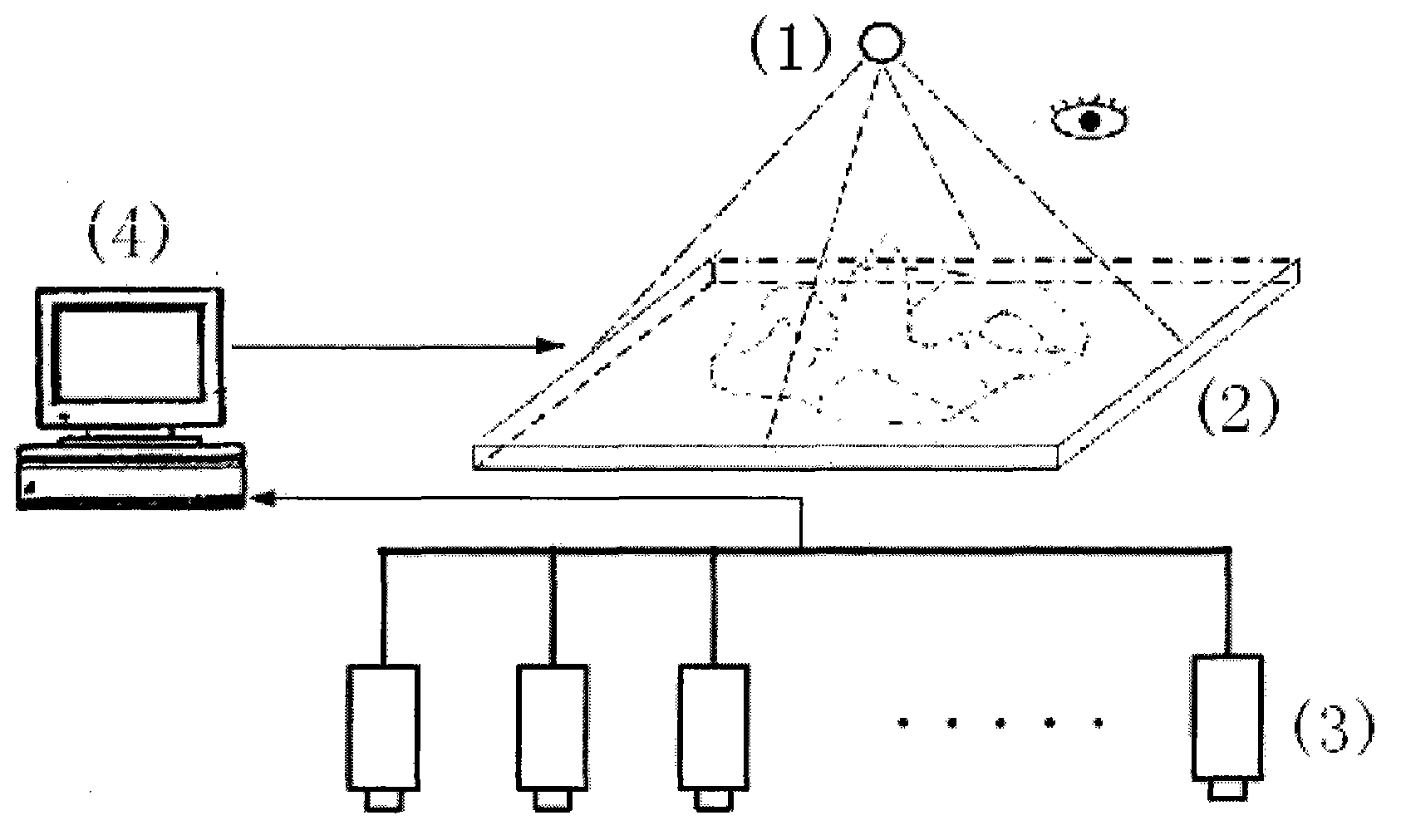

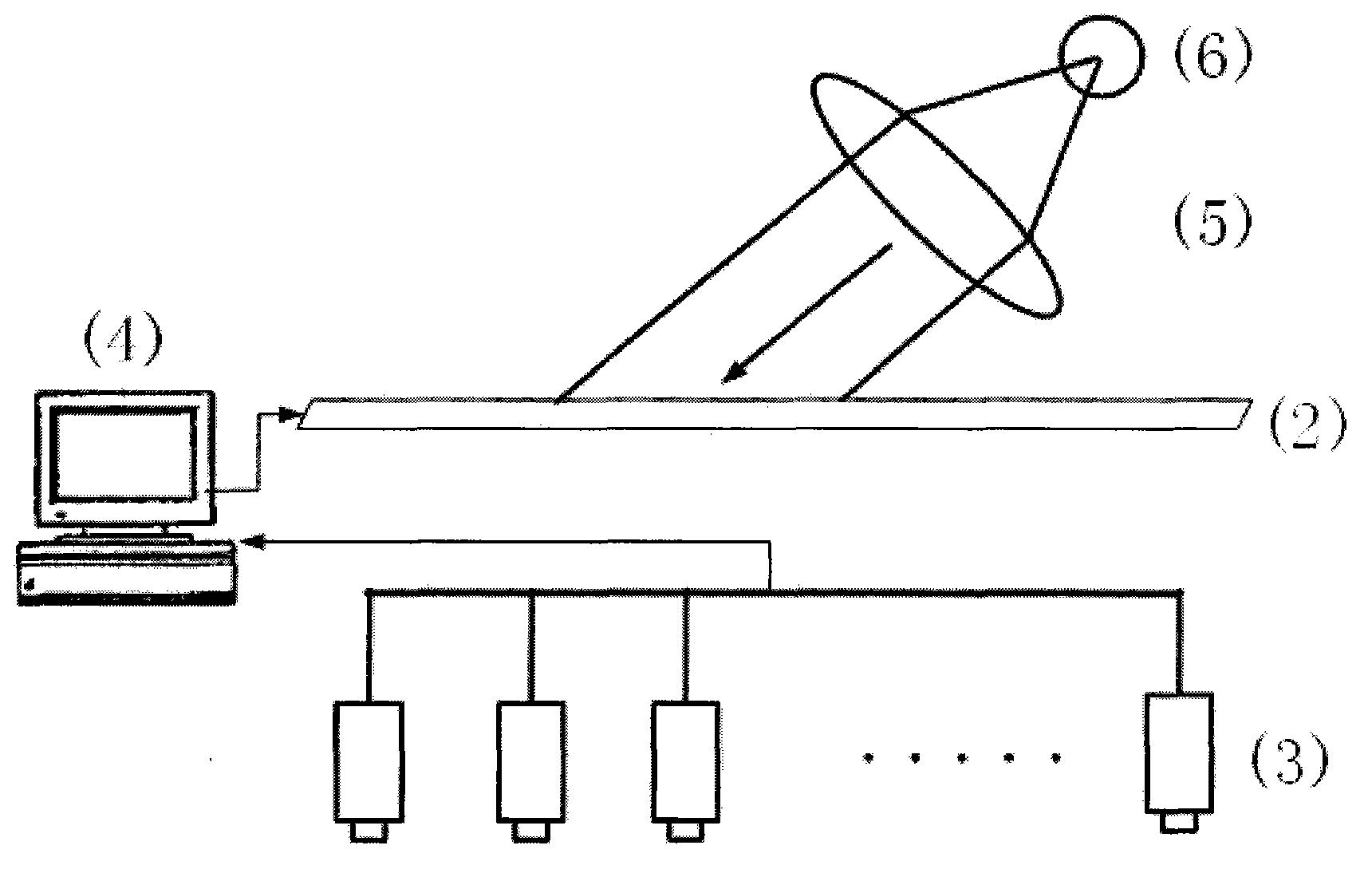

Multiphase flow imaging method based on gamma photon computer tomography imaging technology

InactiveCN107260193AAccurate measurementNot affected by multiphase flow stateReconstruction from projectionRadiation diagnostic image/data processingGamma photonDevice material

The invention relates to a multiphase flow imaging method based on a gamma photon computer tomography imaging technology and belongs to the field of multiphase flow measurement. The multiphase flow imaging method comprises the following steps that 1, a marker is prepared, and a multiphase flow material is marked; 2, a fluid device and a detecting device run; 3, acquisition data is obtained, and a computer is utilized to perform data recombination and reconstruction; 4, a detection image is obtained. The method is not limited by fluid device materials and fluid properties and has higher flexibility, and different imaging structures algorithms can be flexibly adopted according to shapes of devices to be detected.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

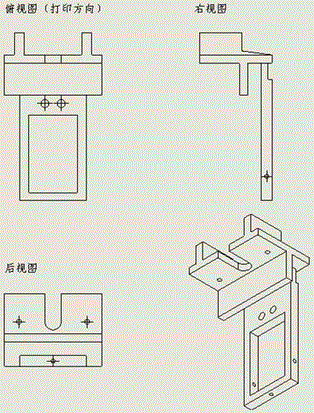

Implementation method based on selective sintering suppression technology for 3D model supporting structure algorithm

ActiveCN105965887AReduce consumptionReduce printing costsAdditive manufacturing apparatusCeramic shaping apparatusSupport pointComputer science

The invention discloses an implementation method based on a selective sintering suppression technology for a 3D model supporting structure algorithm. The implementation method comprises the following steps: a, obtaining a digital file of the model and converting the digital file into a file with a standard STL format; b, numbering the obtained file with the STL format; c, carrying out support and calculation from a triangular plate where a Z-value maximum point lies; d, repeating work of c1 to c4 for a slice plane of Z(j+1) so as to obtain closed curves C(j+1, 1), C(j+1,2) and so on; e, repeating steps c and d until the slice plane reaches the bottom of the mould; and f, for each supporting point, connecting from a starting layer of the corresponding supporting point to an ending layer of the corresponding supporting point to form a line segment in the Z direction, and generating a needed supporting pillar by taking the segment as an axis and taking a radius r as a center. According to the implementation method, a supporting area is completely suppressed during sintering, so that characteristics of loose powder are guaranteed; and due to the action of a suppressant, stripping damages of an area in contact with a component can be as small as possible, so that post-processing needs are reduced.

Owner:GUANGDONG SPRINTRAY 3D PRINTING TECH CO LTD

Deep learning network structure algorithm

InactiveCN106599996AHigh precisionSmall amount of calculationNeural learning methodsOriginal dataAlgorithm

The invention discloses a deep learning network structure algorithm. The deep learning network structure algorithm includes the following steps when determining a connection relation among network layers: S101. collecting a subset of original data from data to be trained; S102. utilizing sample data to perform full-connection training; S103. setting a threshold value, and obtaining a sparse connection table; and S104. utilizing a new sparse connection table to calculate the original data. The deep learning network structure algorithm is suitable for the field of 3D printers, and is suitable for the field of deep learning algorithms. The deep learning network structure algorithm which can improve calculation efficiency and can also ensure calculation precision can be provided.

Owner:DAWNING INFORMATION IND BEIJING

Three-dimensional digital holography photon map

The invention belongs to the field of three-dimensional geographic information display and particularly relates to a holography photon map for displaying a three-dimensional terrain. The holography photon map is composed of a reproducing light source and a hologram recording medium. Specifically, three-dimensional terrain information is obtained through a terrain data collecting system, and three-dimensional data of the terrain is reconstructed by adopting a motion recovery structure algorithm SfM. A three-dimensional terrain hologram is calculated on the basis of a reverse diffraction calculation holographic technology and a diffraction unit lookup table algorithm. The hologram is written into the recording medium, and the photon map is formed. The three-dimensional photon map can display spatial three-dimensional characteristics of the terrain, three-dimensional map display effects of all view angles, multiple angles and high precision are achieved, and the photon map has a data plotting indication function simultaneously and overcomes the shortcoming that an existing map cannot accurately and visually display three-dimensional terrain information.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com