Variable resistor Crowbar structures for low-voltage ride-through of wind power generation and method for realizing variable resistor Crowbar structures

A low-voltage ride-through and variable resistance technology, applied in wind power generation, control of generators, electrical components, etc., can solve problems such as increasing equipment costs, and achieve the effect of avoiding cost increases and realizing simplicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

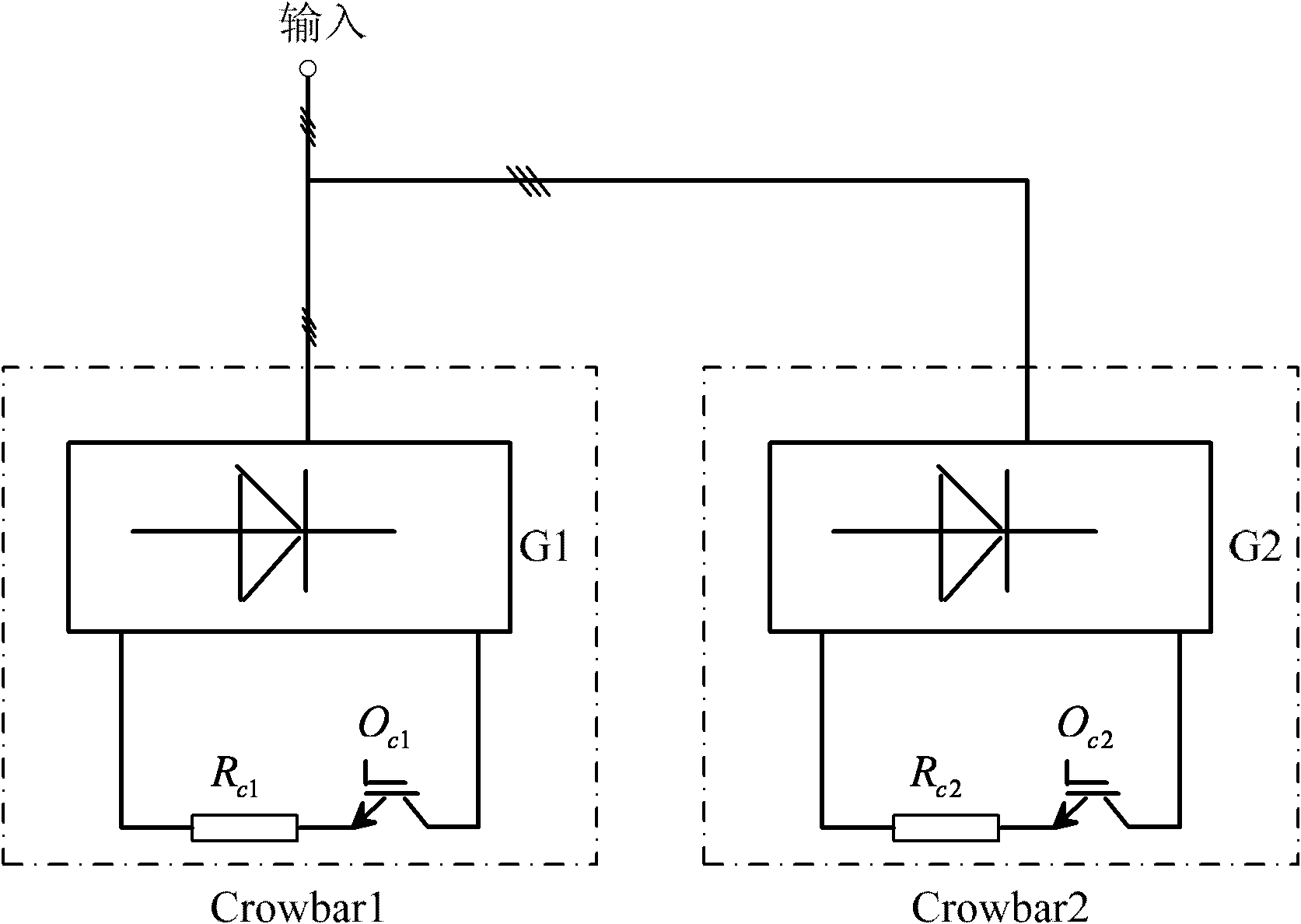

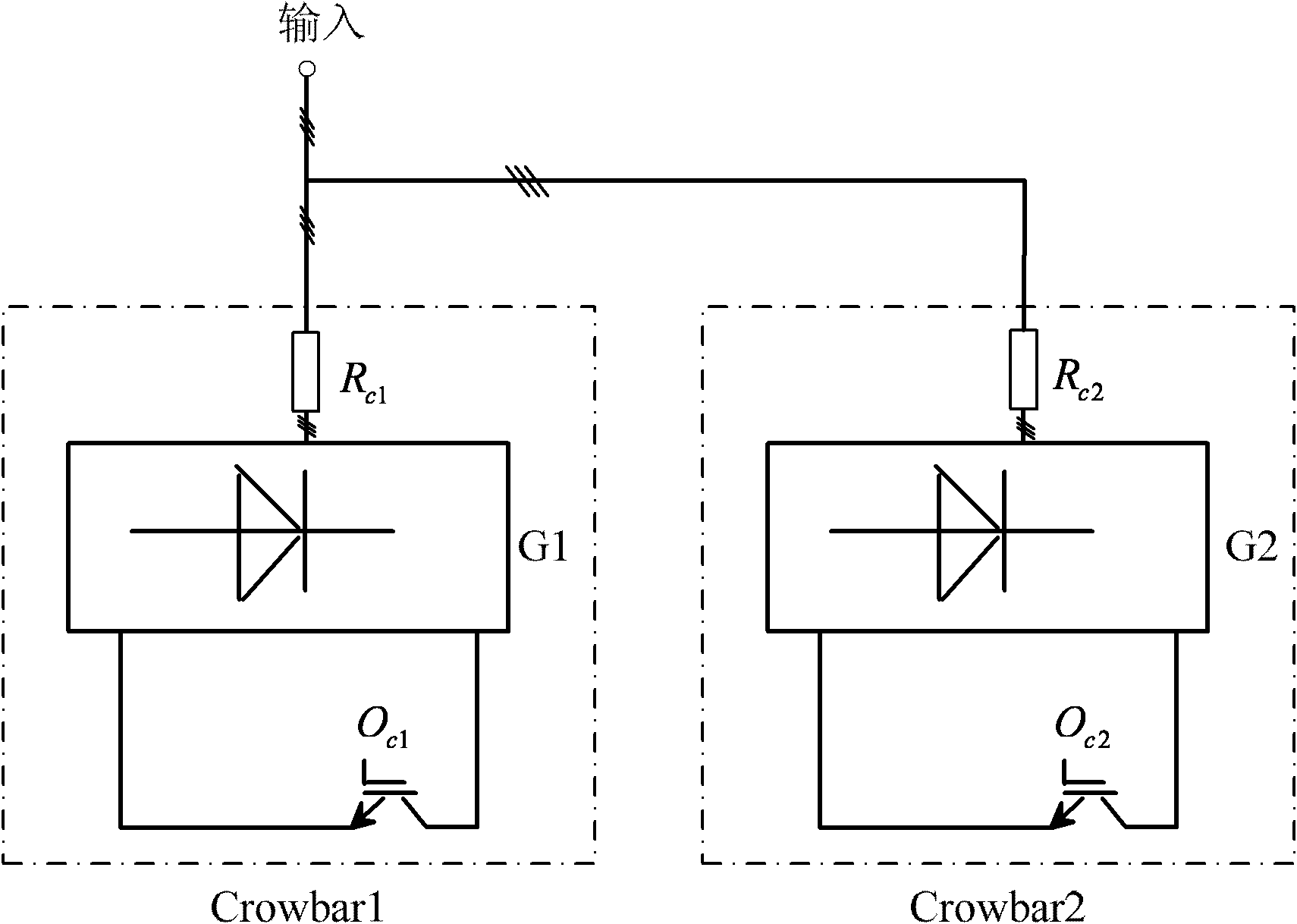

[0046] Embodiment 1 Taking the parallel connection of two crowbars as an example, it expounds the parallel crowbar structure using the typical structure of variable resistance crowbar and the parallel crowbar structure algorithm of the matching typical structure of variable resistance crowbar. And the process of reducing the steady-state current when the motor runs asynchronously after a large slip series Crowbar resistor is as described in the above steps. The reason why it can realize the purpose of the invention is that the variable resistance input of the Crowbar can be realized through the above-mentioned control algorithm. In the specific implementation process of the parallel crowbar structure algorithm of the typical variable resistor crowbar structure, when it is judged that there is a grid voltage drop, the parallel crowbar control is started. When it is judged that there is an overvoltage of the busbar voltage or an overcurrent of the rotor current, control Crowbar1...

Embodiment 2

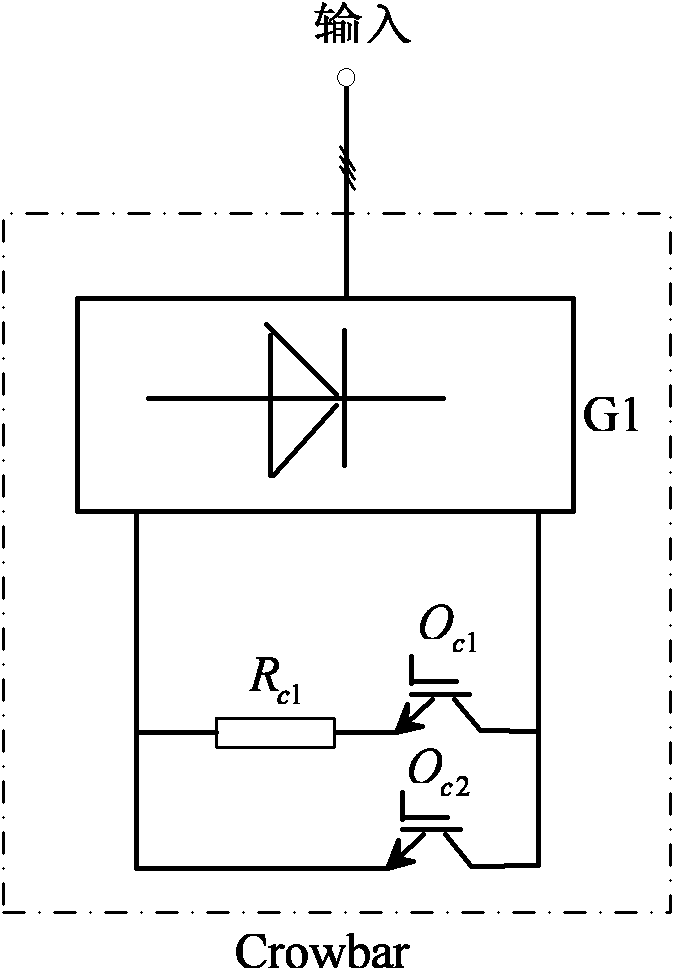

[0060] Embodiment 2 Taking the chopping crowbar structure composed of two controllable devices as an example, the chopping crowbar structure using the typical structure of the variable resistance crowbar and the control algorithm of the chopping crowbar structure with the typical structure of the variable resistance crowbar are explained. In , when it is judged that there is a grid voltage drop, the parallel Crowbar control is started. When it is judged that there is bus voltage overvoltage or rotor current overcurrent, control O c1 closed, the Crowbar bleeds resistor R c1 into the rotor circuit in series, and at the same time at O c1 During the closing period, send a high-frequency pulse signal with a set duty cycle to control the device O c2 , to make closing or opening, when the controllable device O c2 When closed, the controllable device O c1 and bleeder resistor R c1 loops in series or be short-circuited (see image 3 ) or with the controllable device O c2 and ble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com