Supercritical unit coordination control method based on hierarchical model predictive control algorithm

A predictive control algorithm, a technology for supercritical units, applied in control/regulation systems, adaptive control, general control systems, etc., can solve the problem that the network-related functions do not meet the requirements of the power grid, the control variable jumps, and the coordination system is not suitable for being controlled. objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

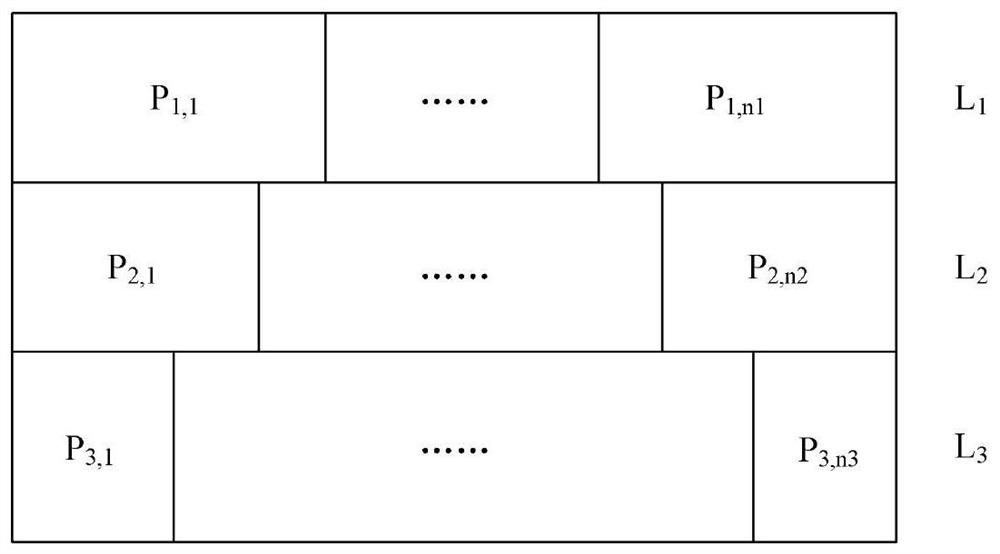

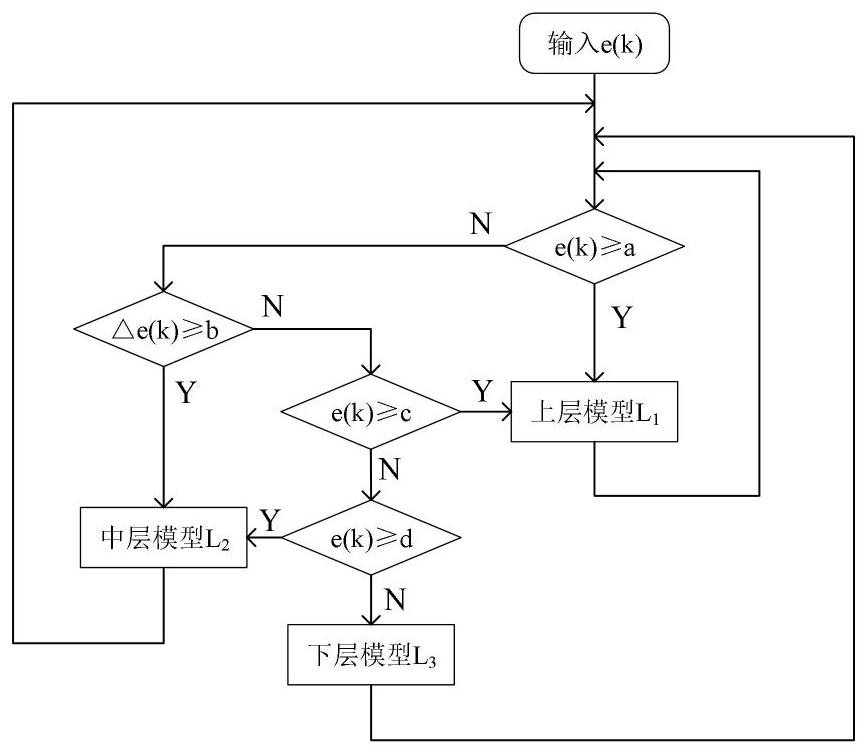

[0062] Taking the 350MW supercritical unit as an example, and in conjunction with the accompanying drawings, the technical solution of the present invention will be described in detail.

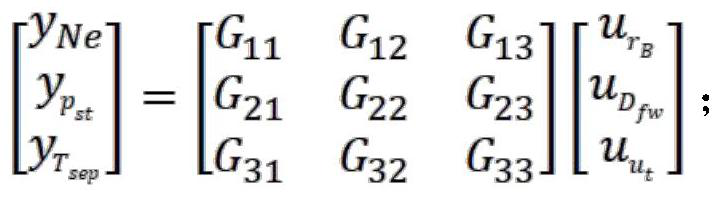

[0063] The controlled object of the 350MW supercritical unit is regarded as a three-input and three-output multivariable system, in which the input quantity of the system is the feedwater flow D fw (t / h), steam turbine door opening u t (%) and the actual amount of coal into the furnace r B (t / h), the output is the real power of the unit N e (MW), machine side main steam pressure p st (MPa) and separator outlet temperature T sep (℃). The mathematical model of 30%-100% Pe for 350MW supercritical unit is identified by using the field step response test data.

[0064] The experimental method is to put the unit into the BASE operation mode under the target working condition, and at the same time put the subsystems into automatic mode. Operators in front of the panel give forward and reverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com