Three-phase voltage type rectifier and control method thereof

A three-phase voltage and rectifier technology, which is applied in the direction of electrical components, AC power input conversion to DC power output, and output power conversion devices. Problems such as difficulties in rectifier debugging and implementation, to achieve high utilization, reduce overshoot and steady-state error, and respond to changes in current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The specific embodiments described here are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

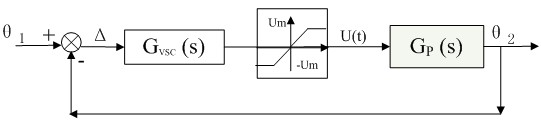

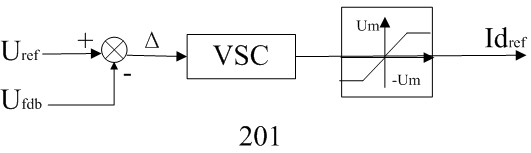

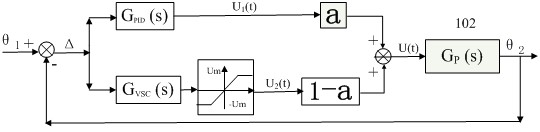

[0036] combined reference Figure 2 to Figure 6 , compared to figure 1 Shown prior art, the three-phase voltage type rectifier of the present invention adopts Figure 4 The first sliding mode variable structure regulator 201 shown replaces the figure 1 The voltage outer loop regulator ② in the prior art shown adopts Figure 6 The weighted combination regulator shown in the alternative is as figure 1 The current inner loop regulator in the prior art shown ③. Specifically, the present invention includes: a sampling module connected to a power supply grid ( figure 2 not shown in ), specifically, the sampling module has a DC side voltage (Uref) sampling module connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com