A metallographic image edge detection method based on mathematical morphology

A mathematical morphology and image edge technology, applied in image analysis, image enhancement, image data processing, etc., can solve the problems of enhancing high-frequency components, long operation time, and large amount of calculation, to achieve accurate positioning, edge continuity and Smooth, targeted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

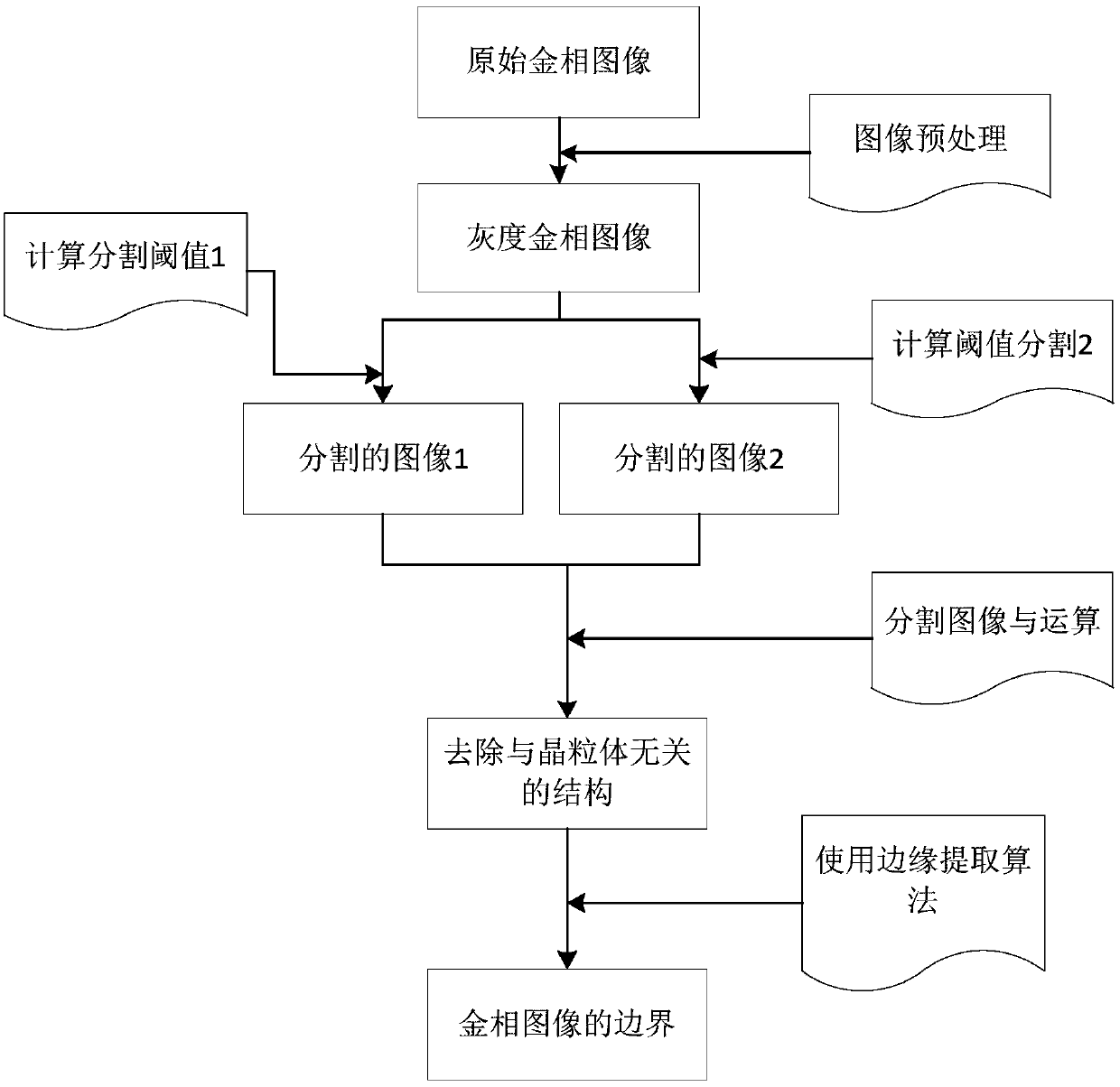

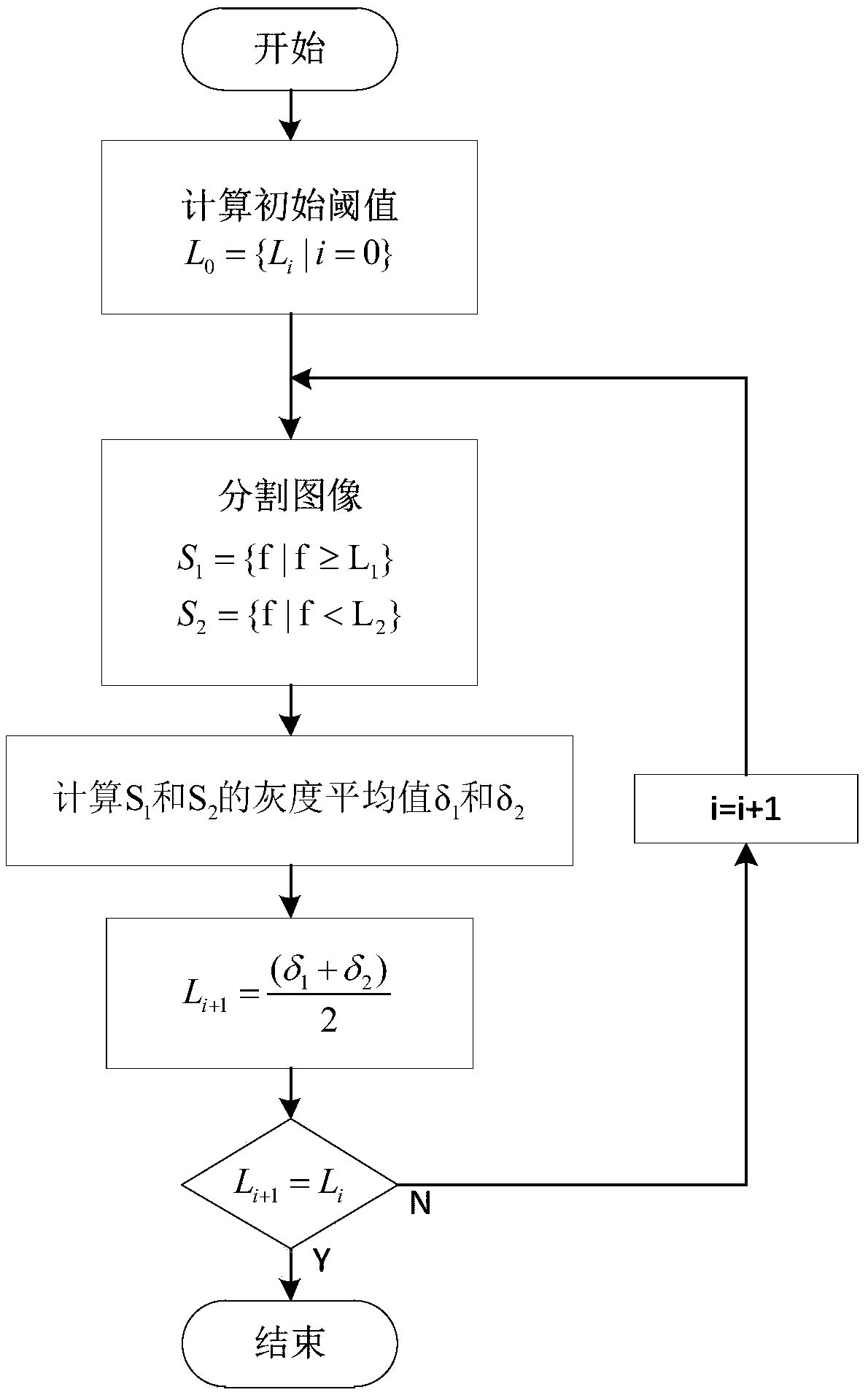

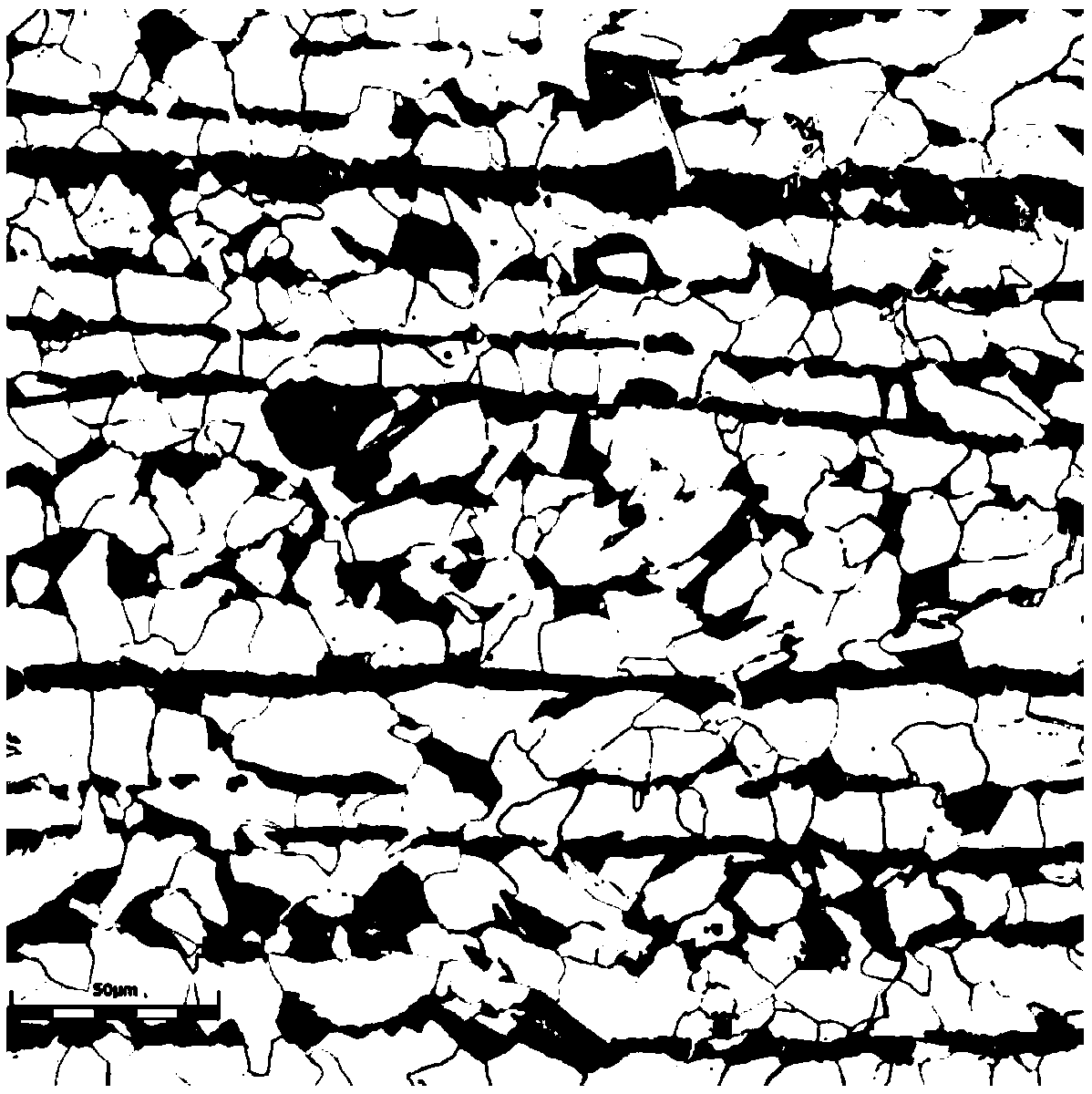

[0053] combine Figure 1~2 , the present invention is based on the metallographic image edge detection method of mathematical morphology, comprises the following steps:

[0054] Step 1, metallographic image acquisition and preprocessing: convert the metallographic image into a contrast-balanced grayscale image, and filter and sharpen the grayscale image to reduce noise and enhance edge information;

[0055] Step 1.1, image acquisition: first collect the metallographic image through an optical microscope and a digital camera, and then input the metallographic image into the computer;

[0056] Step 1.2, image preprocessing: first convert the image into a color space, convert the color image into a single-channel gray image, and then use the mean filtering method to perform mean filtering and sharpening on the obtained metallographic grayscale im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com