Method and device for increasing bulk density of coal charged into top-charging coke oven

A bulk density and dense device technology, applied in the field of increasing the bulk density of top-loaded coke ovens, can solve the problems of poor coke quality at the top, low coal bulk density, and incompactness, etc., to achieve simple structure, increase coke output and Quality, increase the effect of coal loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

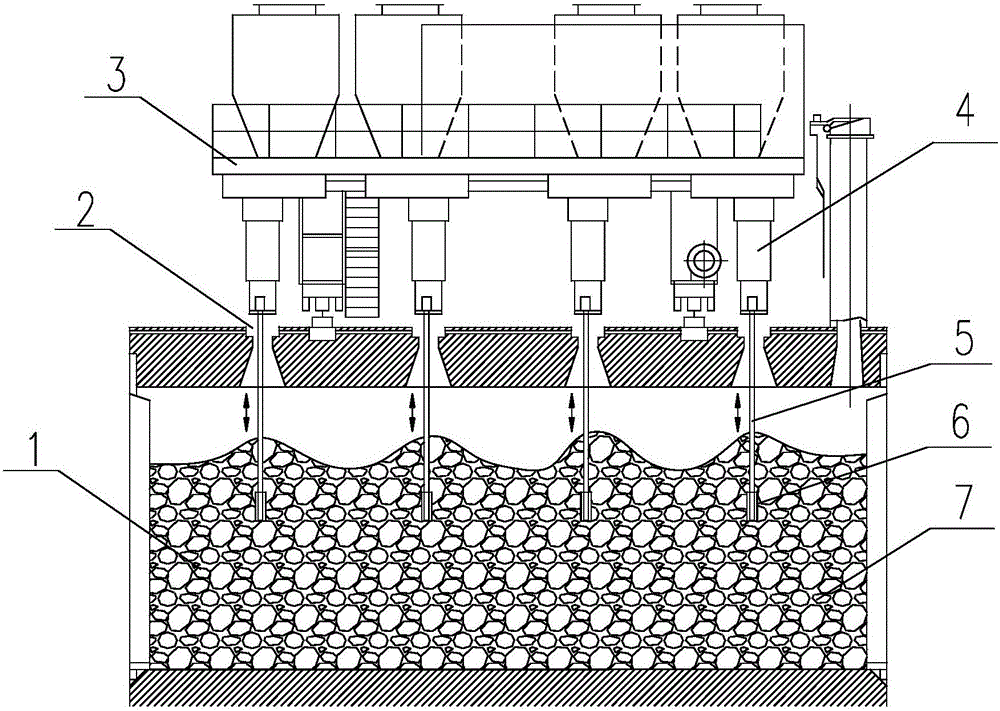

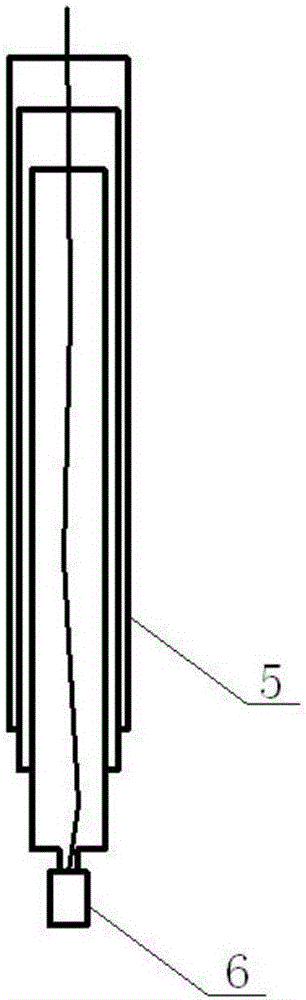

[0016] like figure 1 As shown, a method for improving the coal charging bulk density of a top-loading coke oven according to the present invention, a plurality of coal charging ports 2 are arranged on the top of the top-charging coke oven, and coal charging is simultaneously carried out at a plurality of coal charging ports 2 by a coal charging car 3; The coal unloading device 4 of the coal loading car is provided with a telescopic vibrating compacting device. When charging coal, the vibrating head 6 at the bottom of the telescopic vibrating compacting device extends into 1 / 3-2 of the coal charging height of the coke oven carbonization chamber 1. At the / 3 position, the surrounding coal material 7 is compacted through high-frequency vibration; while coal is being loaded, the vibrating head 6 is lifted synchronously with the rise of the coal loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com