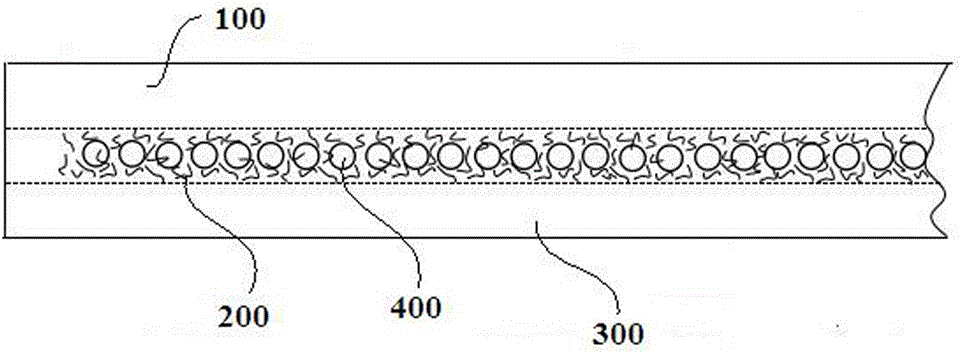

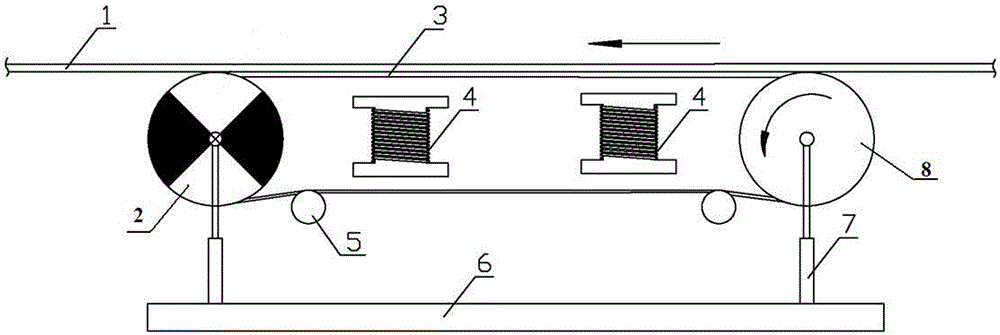

Magnetic conveying belt and magnetic linear driving device

A conveyor belt and magnetic technology, applied in the field of magnetic conveyor belts and magnetic linear drive devices, can solve the problems of sparse distribution, limited magnetic force, and limited number of wire ropes, and achieve the effects of improving stability, extending conveying distance, and reducing the number of transfers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of magnetic rubber with flex resistance, aging resistance and high magnetic requirements: 70 parts of natural rubber, 20 parts of neoprene rubber, 10 parts of nitrile rubber, 1 part of stearic acid, 5 parts of zinc oxide, 1 part of anti-aging agent 4010NA, 1 part of anti-aging agent ODA, 1 part of anti-aging agent RD, 1 part of anti-aging agent BLE, 45 parts of carbon black N234, 15 parts of white carbon black, 1.5 parts of chemical titanate coupling agent, 1.5 parts of silane coupling agent Si69, sulfen 1.5 parts of amide accelerator, 0.3 part of thiuram accelerator, 0.8 part of sulfur, 1.5 parts of cobalt boroacylate, 0.5 part of cobalt naphthenate, formaldehyde donor hexamethylenetetramine and resorcinol donor 3 Parts, 90 parts of rare earth cobalt magnetic powder, 30 parts of ferrite magnetic powder, 180 parts of metal copper-plated magnetic wire, all are parts by mass. The particle size of the magnetic powder is 0.3 μm, the diameter of the metal copper-...

Embodiment 2

[0050] Preparation of magnetic rubber with oil resistance and medium magnetic requirements: 10 parts of natural rubber, 20 parts of neoprene rubber, 70 parts of nitrile rubber, 1 part of stearic acid, 5 parts of zinc oxide, 1 part of anti-aging agent 4010NA, 1 part of anti-aging agent ODA 1 part of anti-aging agent RD, 1 part of anti-aging agent BLE, 50 parts of carbon black N234, 12 parts of white carbon black, 1 part of chemical titanate coupling agent, 2 parts of silane coupling agent Si69, sulfenamide accelerator 2 parts, 0.3 parts of thiuram accelerator, 0.6 parts of sulfur, 2 parts of cobalt boroacylate, 0.5 parts of cobalt naphthenate, 5 parts of formaldehyde donor hexamethylenetetramine and resorcinol donor, rare earths 30 parts of cobalt magnetic powder, 180 parts of ferrite magnetic powder, and 90 parts of metal copper-plated magnetic wire, all of which are parts by mass. The particle size of the magnetic powder is 1.5 μm, the diameter of the metal copper-coated magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com