Yarn retreating equipment and yarn retreating method using yarn retreating equipment

A yarn unwinding and equipment technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of high labor intensity and low production efficiency of staff, and achieve reduced labor intensity, high utilization rate, The effect of less residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

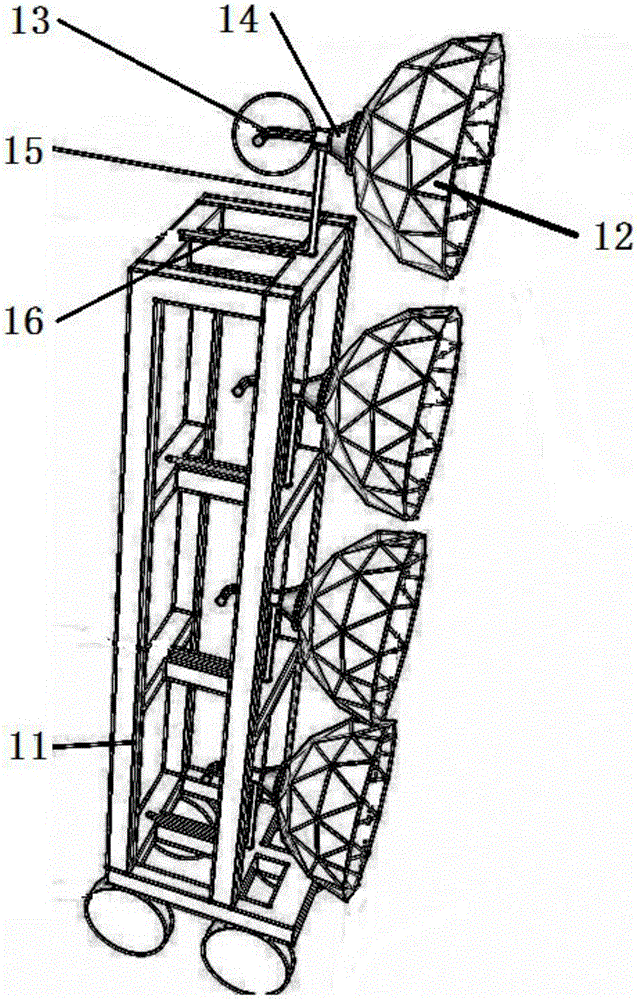

[0039] As mentioned in the background technology section, in the current yarn unwinding process, due to the structural limitations of the existing yarn transporting car, it is inconvenient for the operator to operate when taking and unloading the yarn, and it is time-consuming and laborious. Transferring the raw yarn cake to a special yarn withdrawal rack for yarn withdrawal is not only easy to damage the raw yarn cake, but also the efficiency of yarn withdrawal is low.

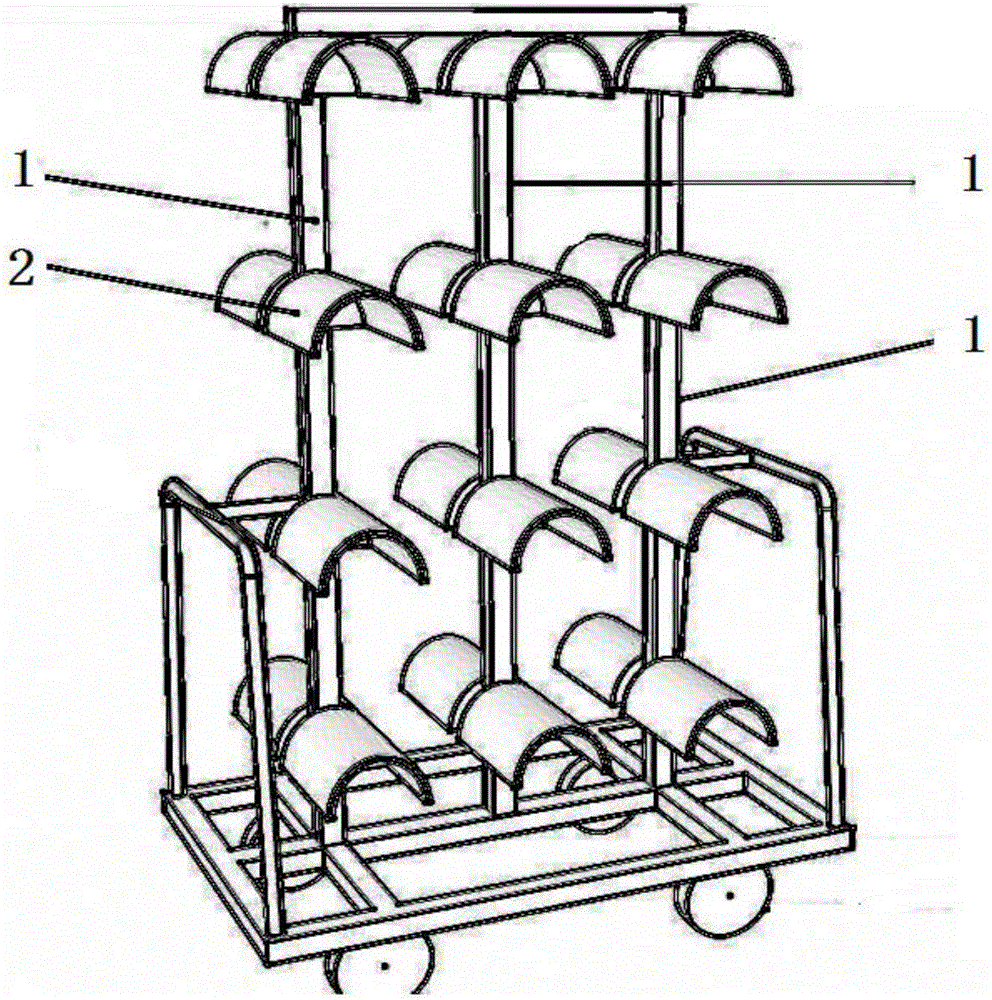

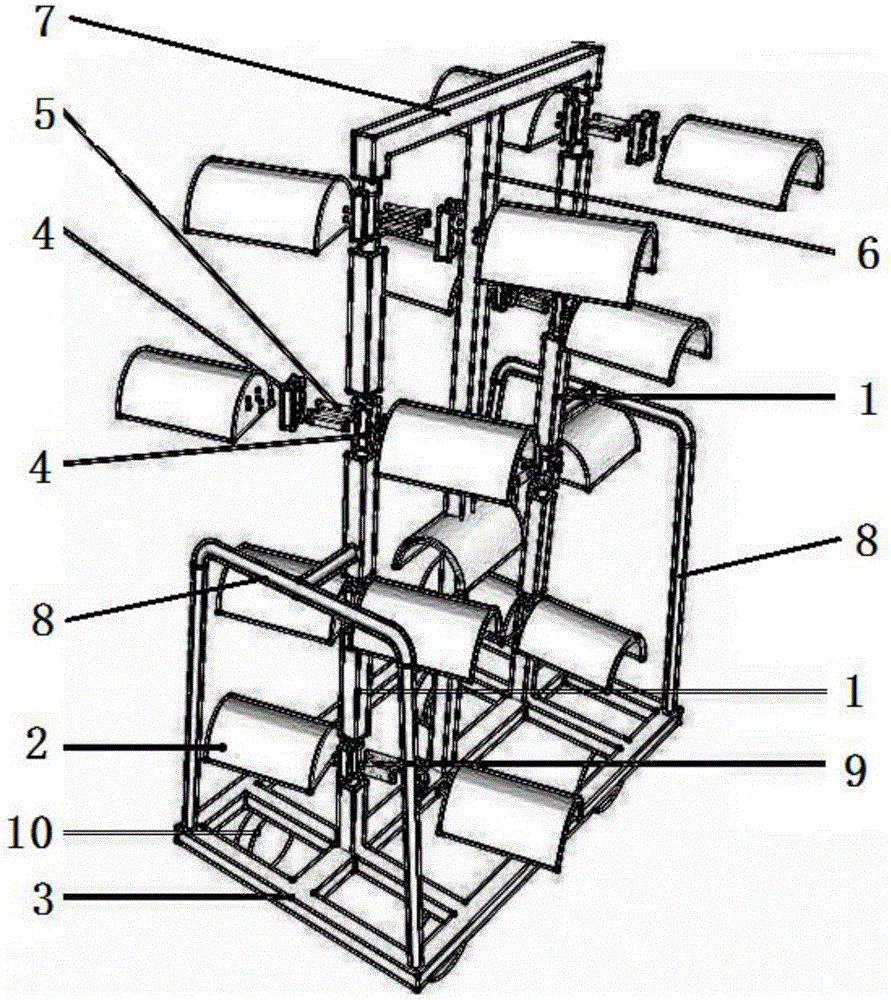

[0040]Based on the above research, the embodiment of the present invention provides a yarn unwinding device, which is transported to the yarn unwinding device by a yarn transporting vehicle equipped with a raw silk cake, so that the raw silk cake and the yarn guide cover on the yarn guide device correspond to each other , so after putting the raw silk cake on the gauze tile on the yarn transporting car, it is not necessary to transfer the raw silk cake to a special yarn unwinding rack for yarn removal, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com