Method for controlling rough rolling squat in continuous hot rolling strip

A technology for hot continuous rolling and strip steel, applied in the field of steel rolling control, can solve the problems of wasting time and unfavorable continuous production, and achieve the effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

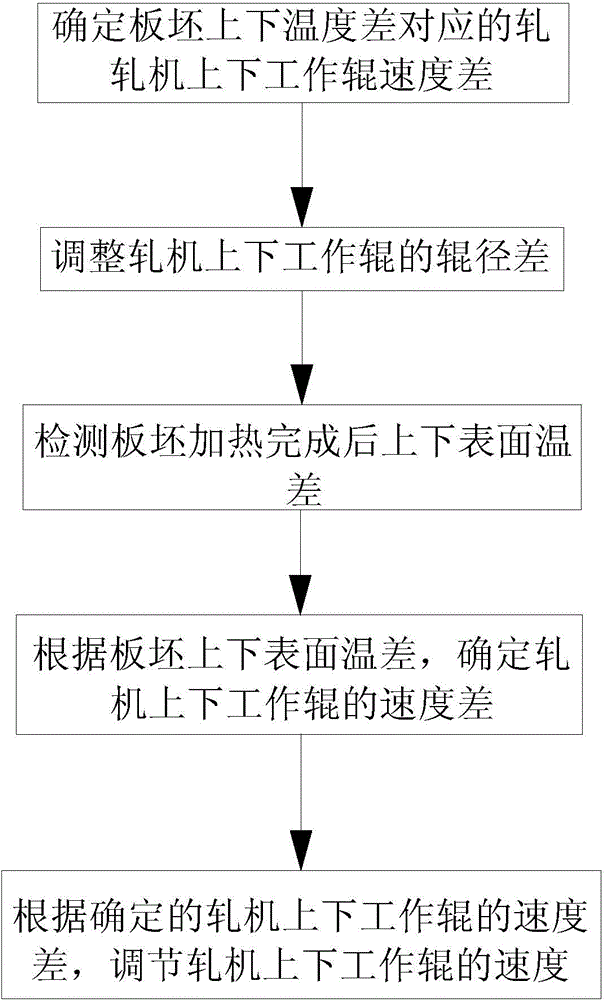

Method used

Image

Examples

Embodiment approach

[0032] A certain steel plant processes according to the outline logic design by adopting the present invention, and the implementation mode is as follows:

[0033] 1. Determine the relationship between △T and the speed difference △V of the upper and lower work rolls of the roughing mill through industrial experiments, and establish an expert database as shown in Table 1.

[0034] 1.1 The temperature difference between the upper and lower surfaces of the furnace slab predicted by the mathematical model of the heating furnace is △T.

[0035] △T=T1-T2 In the formula: △T—the temperature difference between the upper and lower surfaces of the baked slab, in ℃; T1—the temperature of the lower surface of the baked slab predicted by the heating mathematical model, in ℃; T2—the upper surface of the baked slab predicted by the heating mathematical model Surface temperature, in °C.

[0036] △V=V1-V2; where: △V—the speed difference between the upper and lower work rolls of the rolling mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com