Rolling process of hot rolled steel sheet

A technology of hot-rolled steel plate and operation method, applied in the direction of metal rolling, metal rolling, rolling mill control device, etc., which can solve the unbalanced extension of steel on both sides of the strip, many accidents of piled steel, time lag of leveling control, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following specific examples are given to illustrate the present invention. The embodiments are only used to further illustrate the present invention, and do not represent the protection scope of the present invention. The non-essential modifications and adjustments made by others according to the present invention still belong to the protection scope of the present invention.

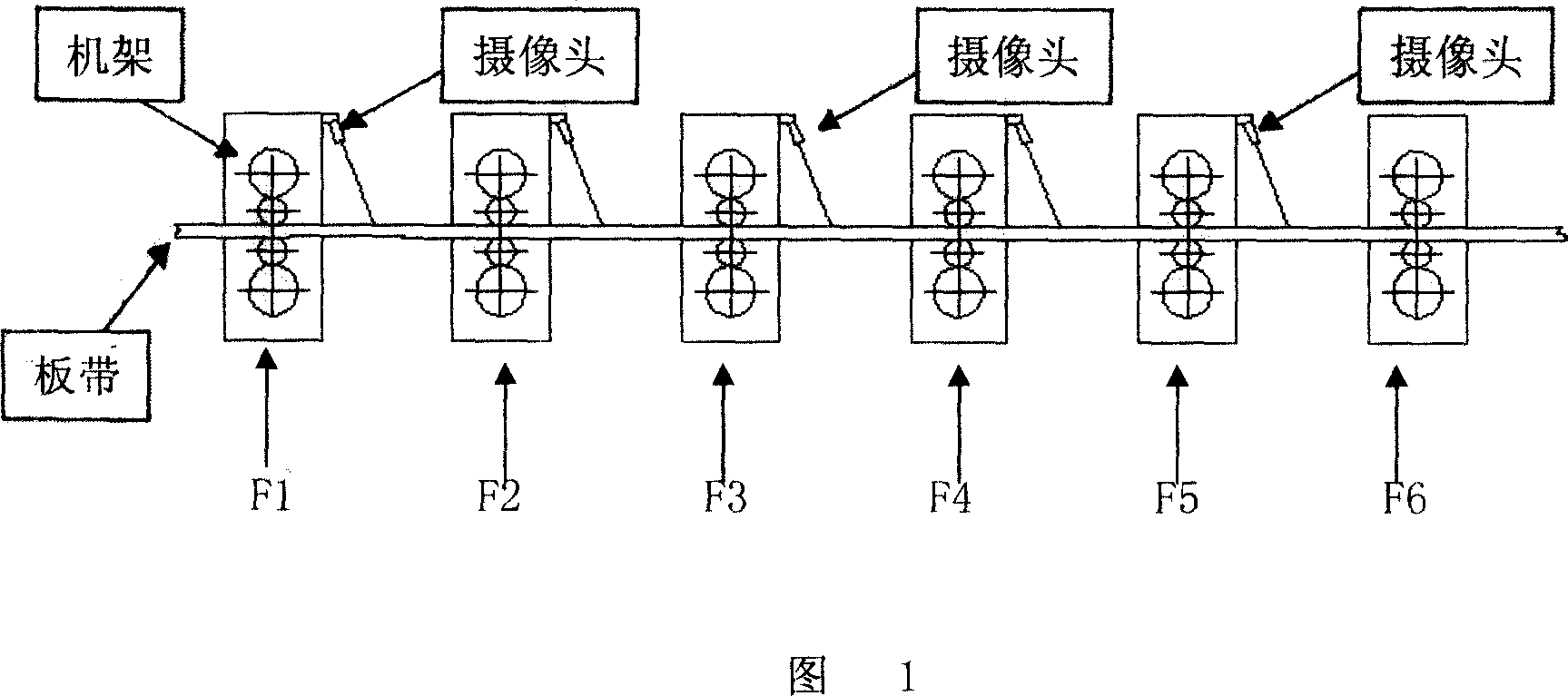

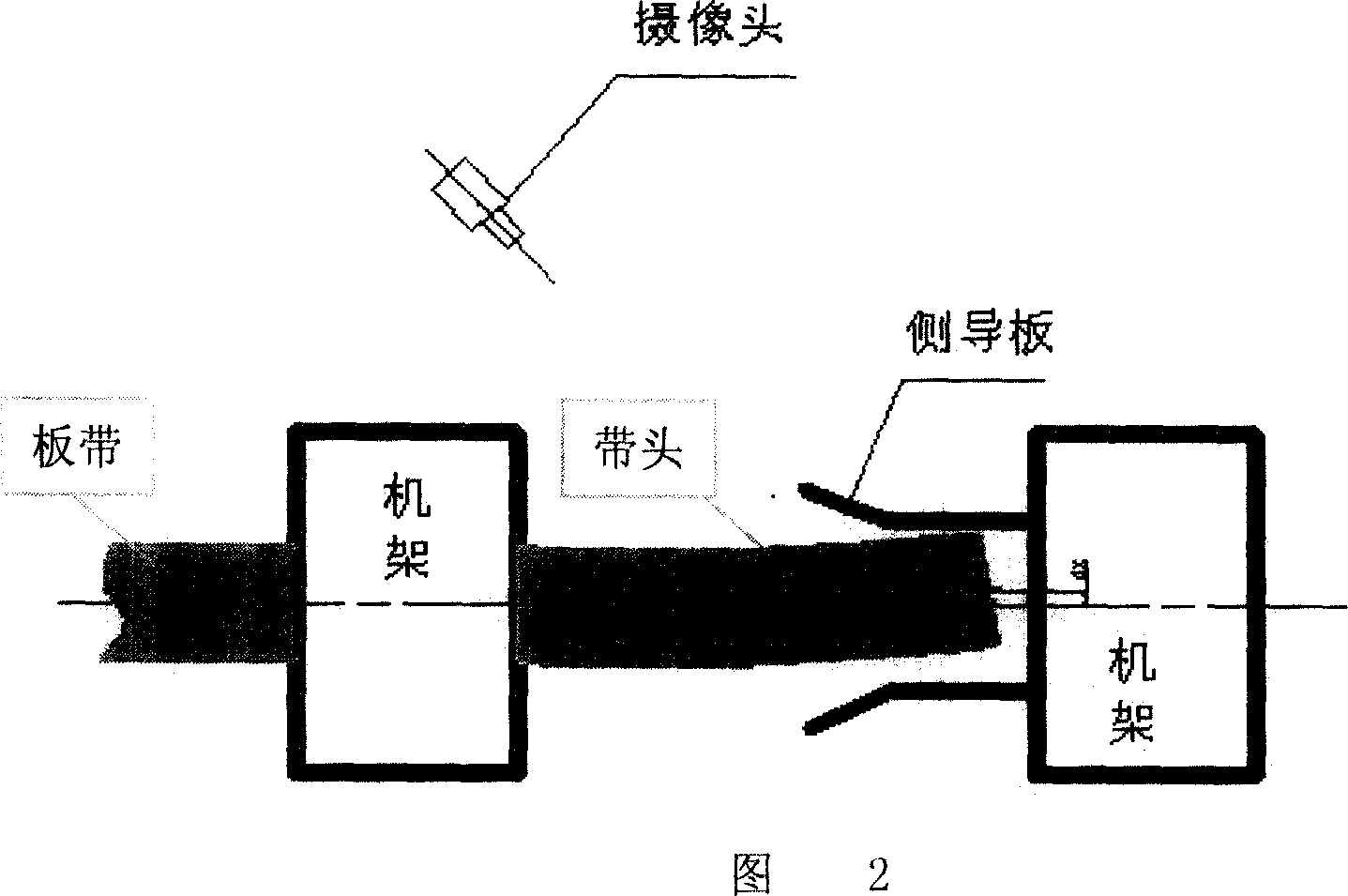

[0021] Install the camera device directly above the frame F1-F6 of the continuous rolling mill. The camera layout is shown in Figure 1, and the terminal display of the camera device is installed on the console. The operator observes the deviation of the strip through the camera: as shown in Figure 2, the camera looks down and observes that the strip head deviates to one side. By observing the deviation trend of the strip, the unbalanced deformation of the strip was discovered in the early stage, and the following three schemes were used to adjust the strip in time to return to the centerline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com