Automatic head and tail residue monitoring method of hot rolling strip steel

An automatic monitoring and hot-rolled strip technology, applied in the direction of tail-end control, etc., can solve the problems of inadvertent observation, unclear observation, missed detection or misjudgment, etc., to reduce the risk of scrap steel and accident expansion , Improve production stability, avoid missed detection and misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The method for automatic monitoring of the hot-rolled strip head and tail of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

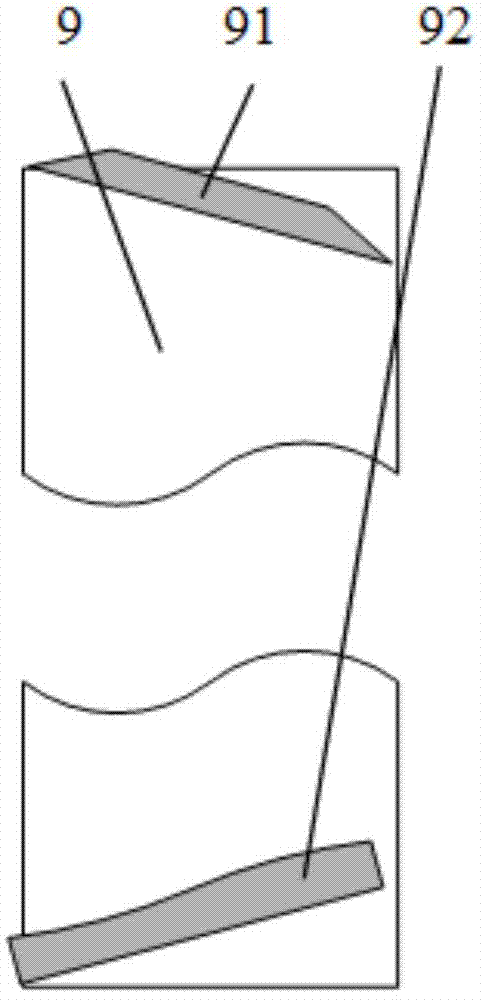

[0044] image 3 A schematic diagram of the leading and tailing phenomena. After the head of strip steel 9 is cut by flying shears 4, tongue 91 is not completely separated from strip steel 9, but rides on strip steel 9, enters descaling box 5 with the form of folding. Similarly, after the tail of the strip steel 9 is cut by the flying shears 4, the fish tail 92 is not completely separated from the strip steel 9, and enters the descaling box 5 in a folded form.

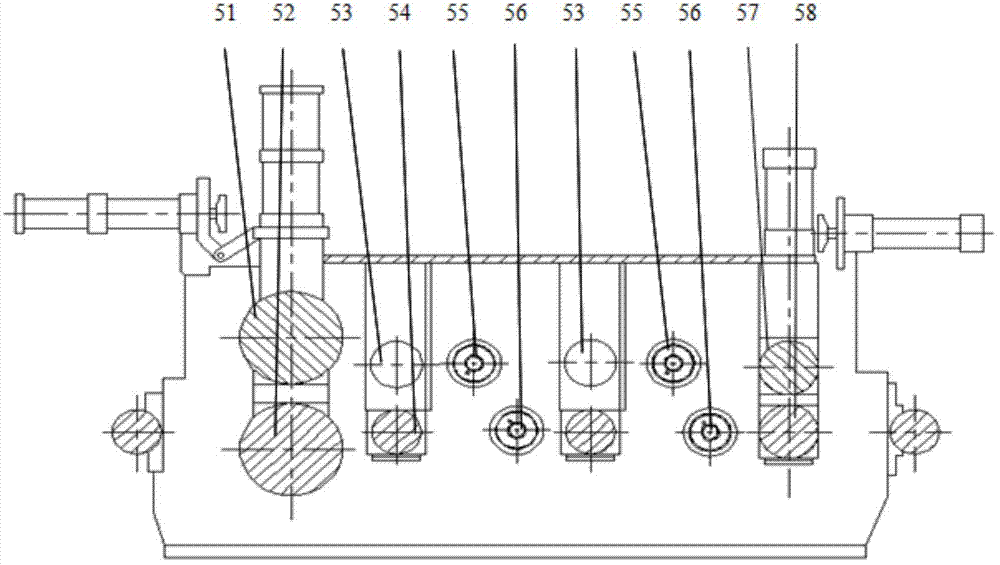

[0045] figure 2 It is a structural schematic diagram of phosphorus removal box 5. The phosphorus removal box 5 includes an upper pinch roller 51 at the entrance, a lower pinch roller 52 at the entrance, a water collector 53, a roller table 54 for the phosphorus removal box, an upper water header 55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com