Method for improving yield of reciprocating rolled plate

A technology of yield and plate, applied in the field of cold rolling of plates, can solve the problems of low yield and excessive thickness of strip head and tail, and achieve the effects of increasing yield, improving yield and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

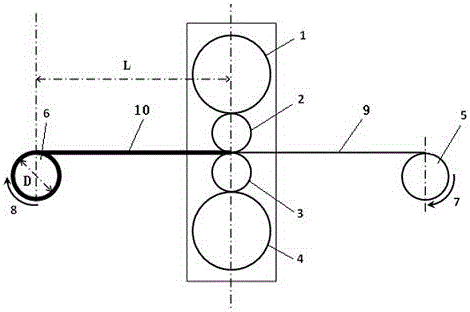

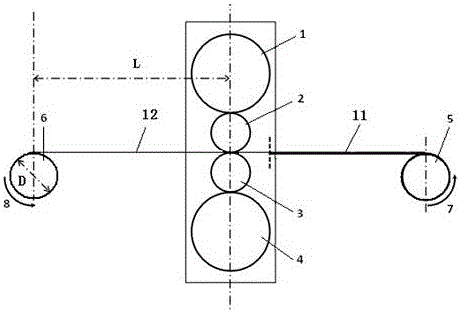

[0023] The invention solves the problem that the strip head and the strip tail cannot be rolled and the thickness exceeds the standard and the yield is low when the reciprocating rolling mill works by welding the strip leader at the strip head and the strip tail.

[0024] The method of the present invention adopts the following steps:

[0025] a. Uncoiler for pickling strip to be rolled;

[0026] b. On-line welding of the strip head leader, the length of the strip head leader is greater than the sum of the distance from the centerline of the work roll of the rolling mill to the centerline of the coiler mandrel and the length wound on the mandrel of the coiler;

[0027] c. Before the first rolling pass, wind the strip head leader on the mandrel of the coiler of the coiler on the other side for three turns to establish the tension required for rolling;

[0028] d. After the tension required for rolling is established, the first rolling pass is carried out;

[0029] e. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com