Method for controlling strip steel head and tail widths through coil box production process

A technology of width control and production process, applied in the direction of tail end control, metal rolling stand, metal rolling mill stand, etc., can solve the problems of economic loss and low control precision of product width and size, and achieve the improvement of control precision and the improvement of physical objects. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

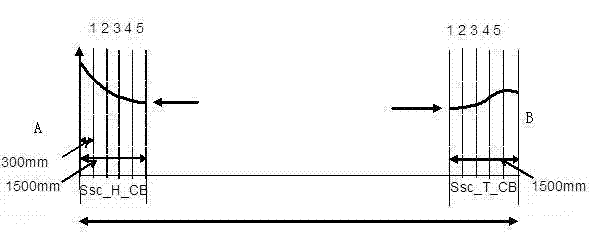

[0013] 1. According to the coiling method of the hot coil box, improve the head and tail short stroke width control (SSC) algorithm, S REF = S SU + S SS, , where S SU is the setting value of vertical roll opening, S SS is the adjustment amount (the head and tail of the strip are each 1.5m long and every 300mm is an adjustment point, a total of 5 points to achieve the ideal product head and tail width control accuracy), S REF Control parameter for short stroke width.

[0014] a) Check whether the current rolled strip steel adopts the hot coil box coiling process;

[0015] b) If the hot coil box is used for coiling, the S in the head and tail short stroke control algorithm SS Take the width control parameter (Ssc_H_CB) at the head of the strip and take the width control parameter (Ssc_T_CB) at the tail of the strip respectively

[0016] Such as figure 1 As shown, the strip head and tail short stroke control is to adjust the opening of the vertical roll every 300mm for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com