Device for influencing the temperature distribution over a width

A technology of width and cooling device, used in temperature control, length measuring device, workpiece cooling device, etc., can solve the problems of unstable strip size and abnormal section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

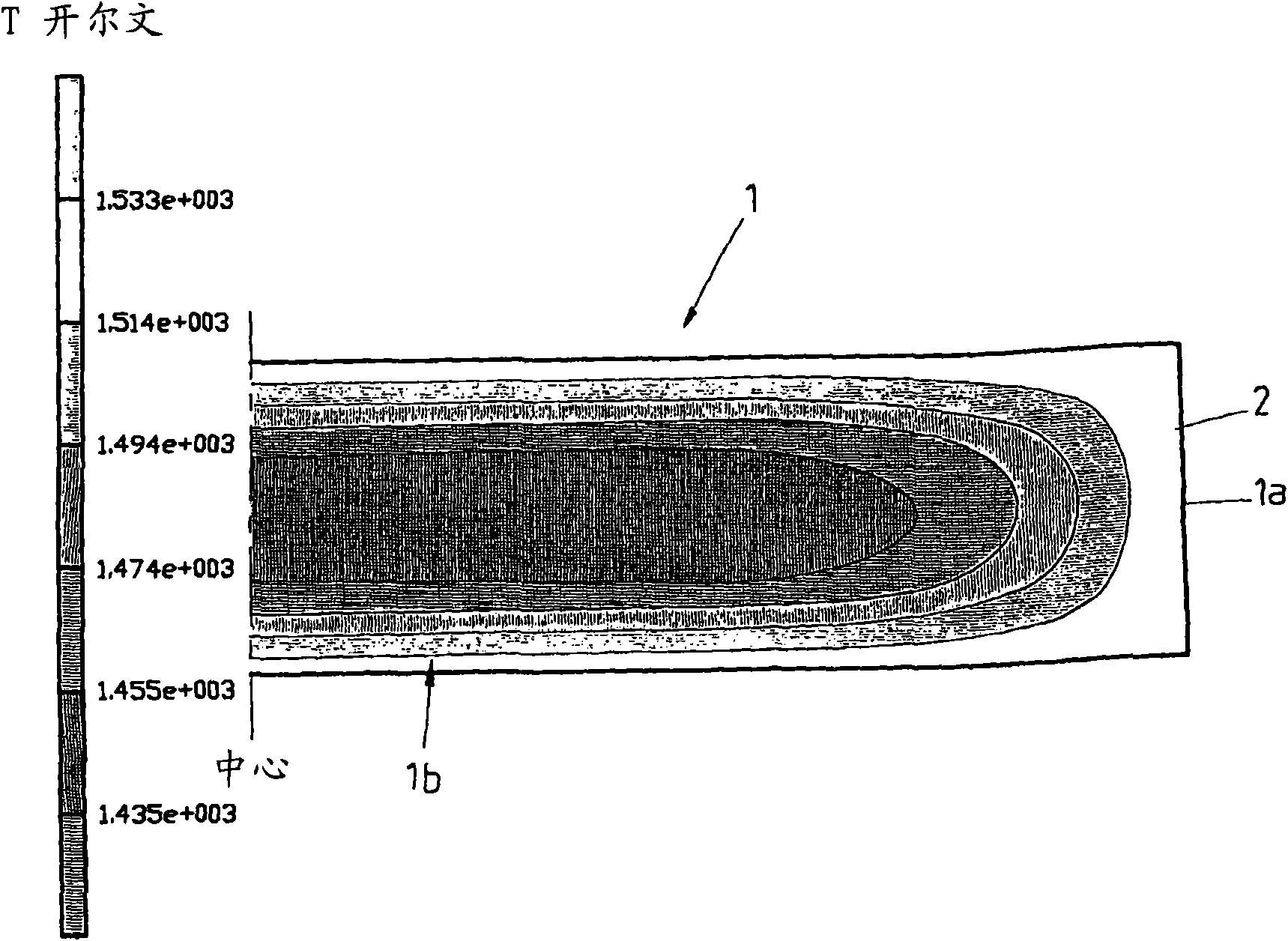

[0044] figure 1 A representation of one half of a slab 1 is shown, in which the temperature distribution is clearly indicated by means of color differences, the lighter the shade or gray gradient, the higher the temperature. The slab 1 has been heated unevenly when leaving the conventional furnace of the hot strip rolling plant, which can also be attributed to a too short residence time in the furnace, which may be the result of fully utilizing the furnace capacity. The slab 1 is hotter on the surface and on the edge 1a or on the slab edge 2 than in the core 1b, which is depicted darkly, for example. The slab 1 is therefore not heated optimally and uniformly.

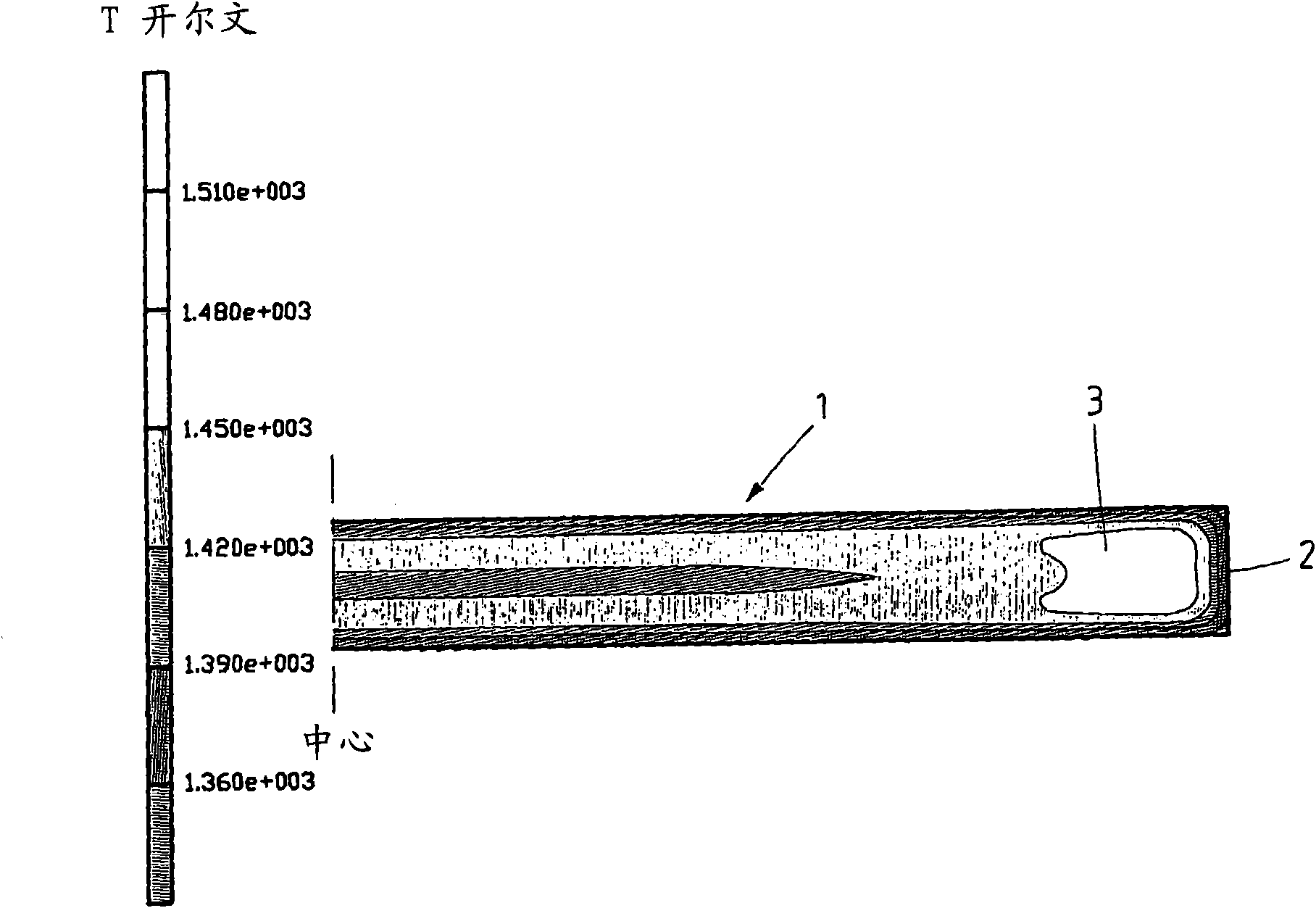

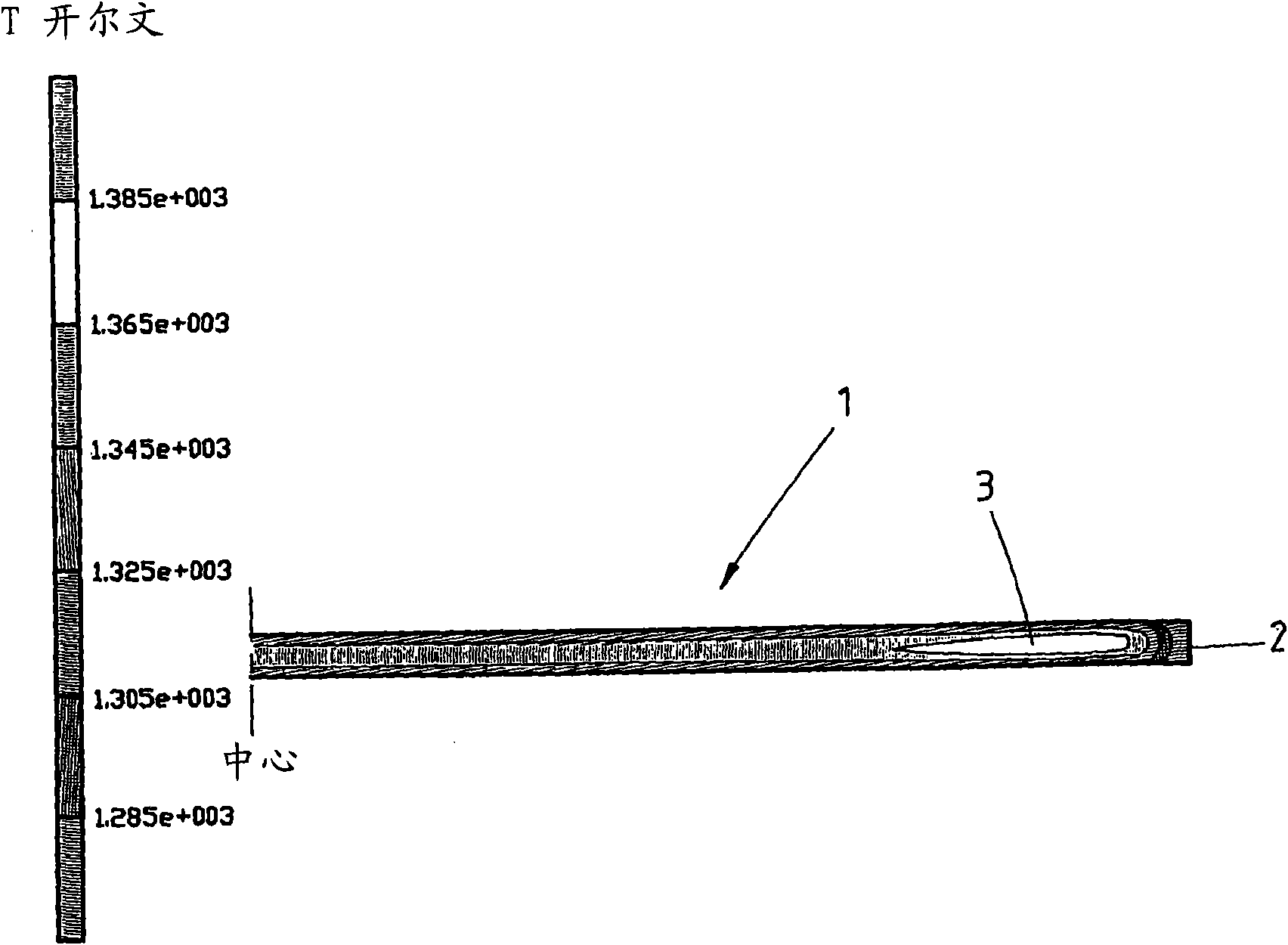

[0045] During rolling by means of a blooming mill, the cross-sectional temperature of the slab 1 changes, so that the rolled slab 1 obtains, for example, a cross-sectional temperature which is the same as at figure 2 and image 3 The cross-section temperature shown in . The strip edge 2 is further cooled by rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com