Control method for stopping reversible cold-rolling mill

A technology of rolling mill control and control method, applied in the direction of rolling mill control device, metal rolling, tail end control, etc., can solve the problems of high parking positioning accuracy, low accuracy of coil length, affecting normal rolling, etc. The effect of improving position accuracy and increasing product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

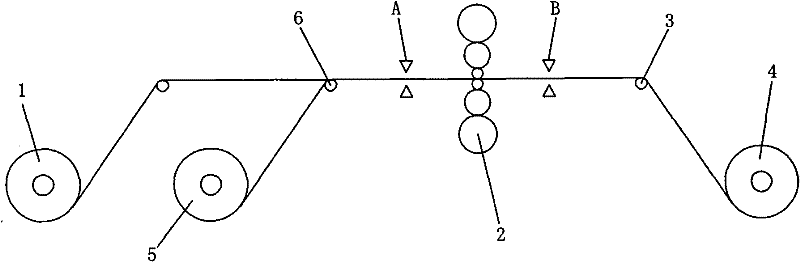

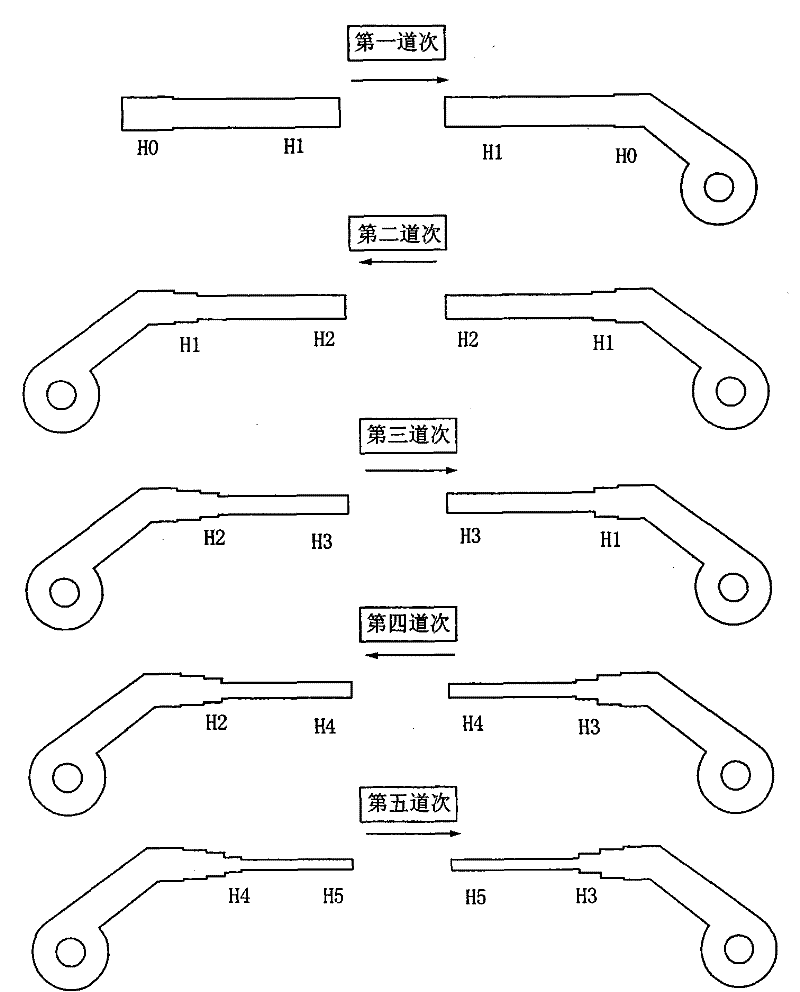

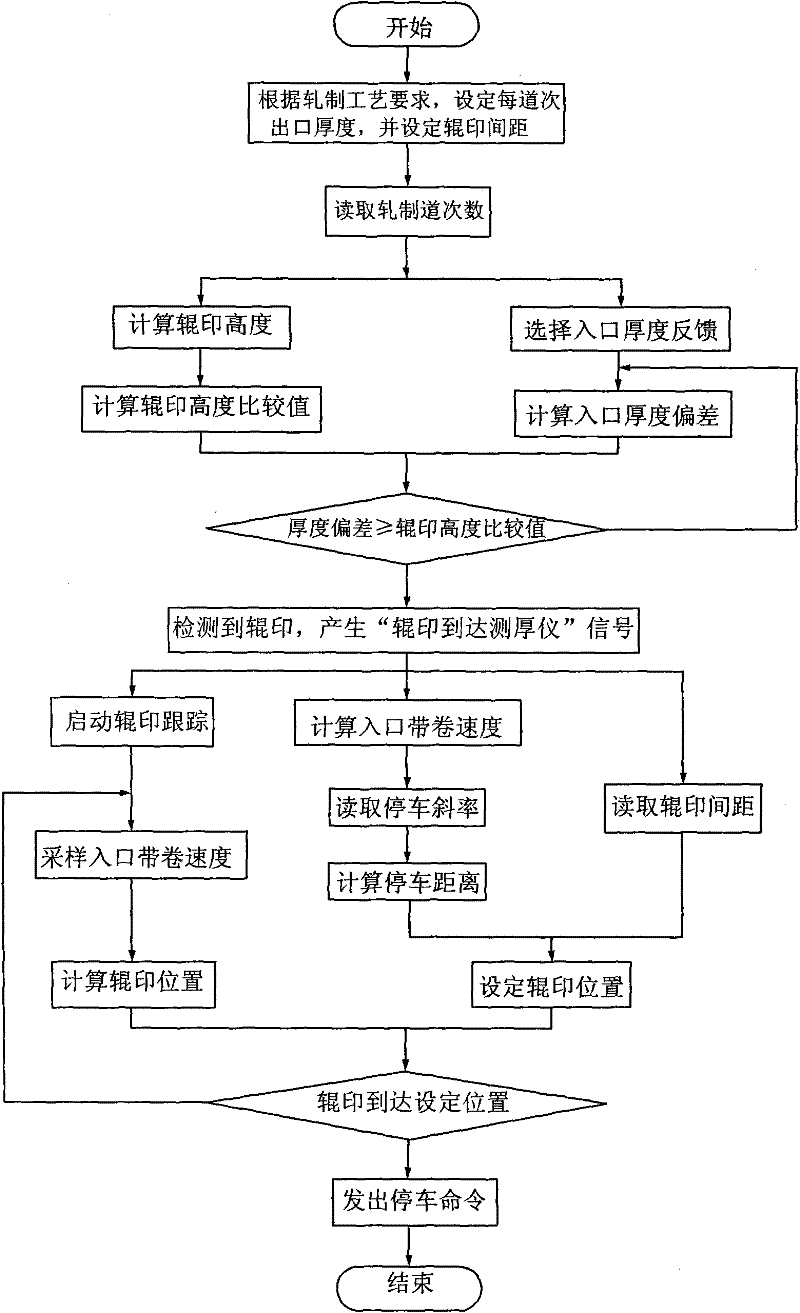

[0032] The parking control method of the reversing cold rolling mill in this embodiment is illustrated by taking the existing single-stand reversing cold rolling mill as an example, and its process layout structure is as follows figure 1As shown, one uncoiler 1, one six-high reversing rolling mill 2, two coilers 4 and 5, and two thickness gauges A and B are arranged at the front and rear rolling entrances of the rolling mill 2 respectively. Firstly, mainly based on the initial information of the steel coil and the rolling target value, calculate the passes required for rolling, as well as the rolling speed, reduction ratio, front and rear tension, and roll bending force of each pass, and then send it to the actual There is a rolling mill control system. In this embodiment, it is determined to carry out five-pass rolling, and the thickness H of the incoming material of the coil is 0 : 3.5mm, finished coil thickness (rolling target value) H 5 : 1.0mm, strip threading speed 0.5...

Embodiment 2

[0050] The reversible cold rolling mill parking control method of this embodiment is an improvement on the basis of Embodiment 1, as Figure 4 As shown, except that the same steps as in Embodiment 1 are different:

[0051] 1. In step 4), when the existing rolling mill control system generates the signal of "the roll print reaches the position of the thickness gauge", the existing rolling mill control system starts the stop timing of each pass;

[0052] 2. In step 5), the existing rolling mill control system calculates the stop delay of each pass according to the coil speed and the rolling mill stop slope of each pass, or the existing rolling mill control system directly reads the The test sets the stop delay for each pass. Still taking the second pass as an example to calculate the parking delay as follows:

[0053] When the signal of "the roll mark reaches the position of the thickness gauge" is generated, it means that the roll mark is 2.5m away from the rolling mill, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com