Method for preventing slab from sliding at inlet of fixed width machine

A technology of sizing machine and entrance, which is applied in rolling mill control device, metal rolling, manufacturing tools, etc., can solve the problem of kowtow slab slippage, etc., and achieve the effect of preventing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

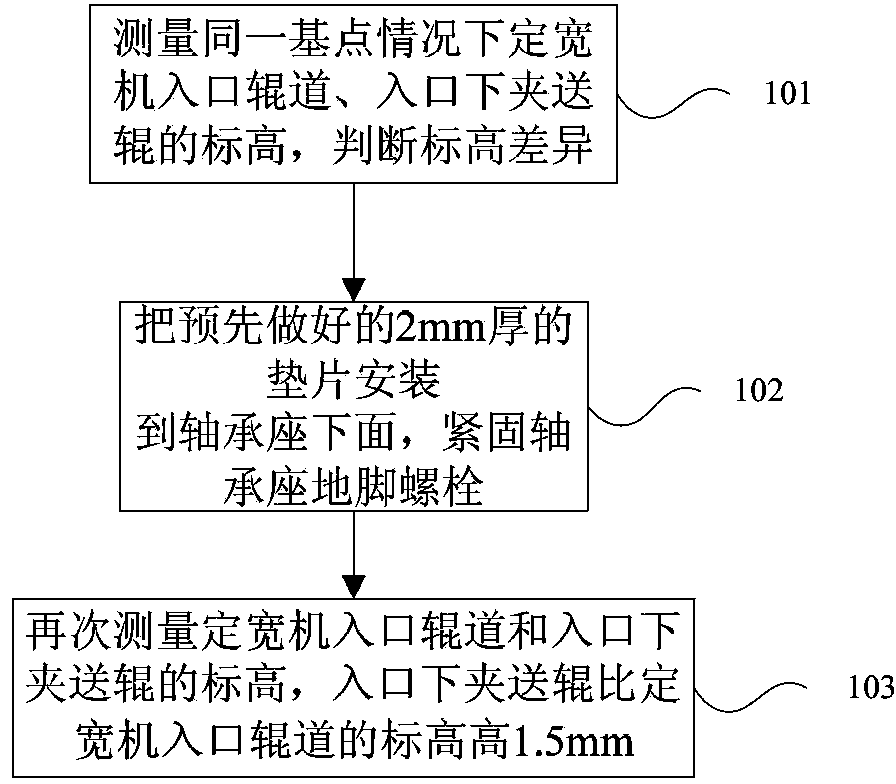

[0009] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

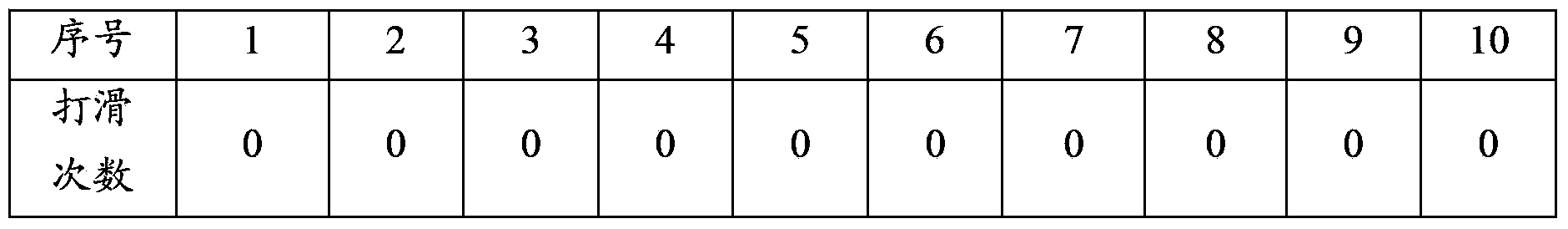

[0010] In the embodiment of the present invention, by analyzing the reason why the knurling slab slips at the entrance of the width-fixing machine, the elevation of the entrance roller table and the pinch roller under the entrance of the width-fixing machine is measured, and the elevation of the pinch roller under the entrance is increased, so that the kowtow slab enters the width-fixing machine After the lower pinch roller at the entrance of the fixed-width machine, even if the kowtow is placed on the lower guide roller at the entrance of the width-fixing machine and the slab is arched, the lower pinch roller and the slab at the entrance of the width-fixing machine will still keep in contact, and there will be no false contact problem, so that it can effectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com