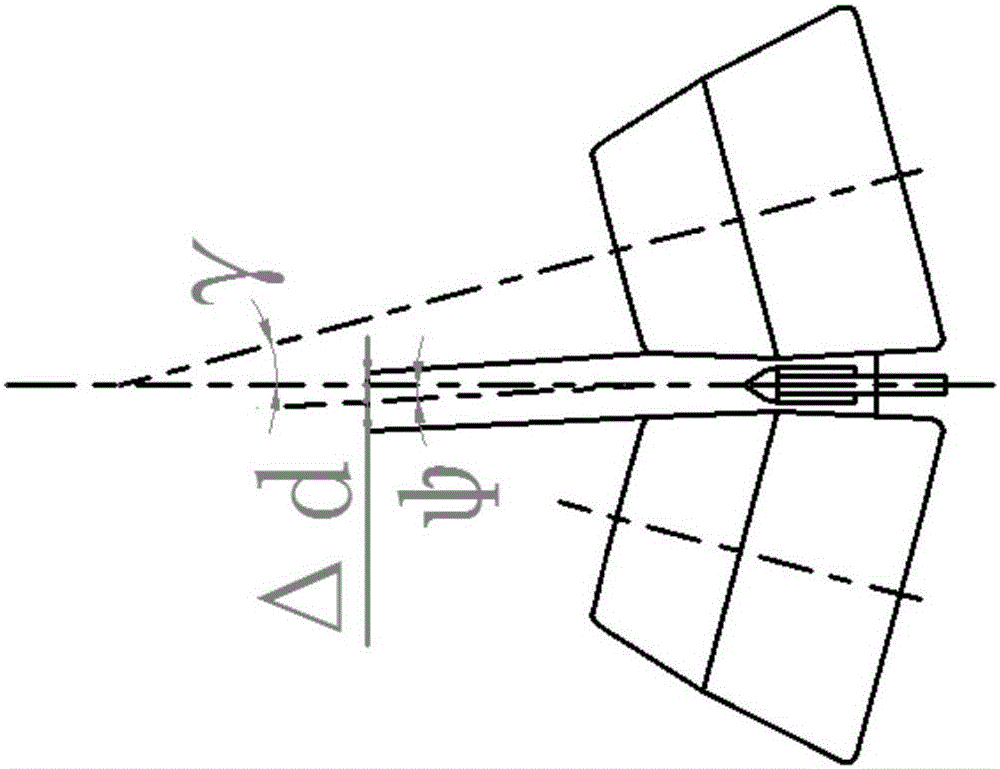

Method for controlling tail wiggling quantity of inclined rolling perforator

A technology of cross-rolling piercing and tail swing, applied in the direction of tail end control, rolling mill control device, metal rolling, etc., can solve the problems of excessive capillary ellipse, safety accidents, aggravating the deviation of the tube billet from the rolling line, etc. The effect of improving quality and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

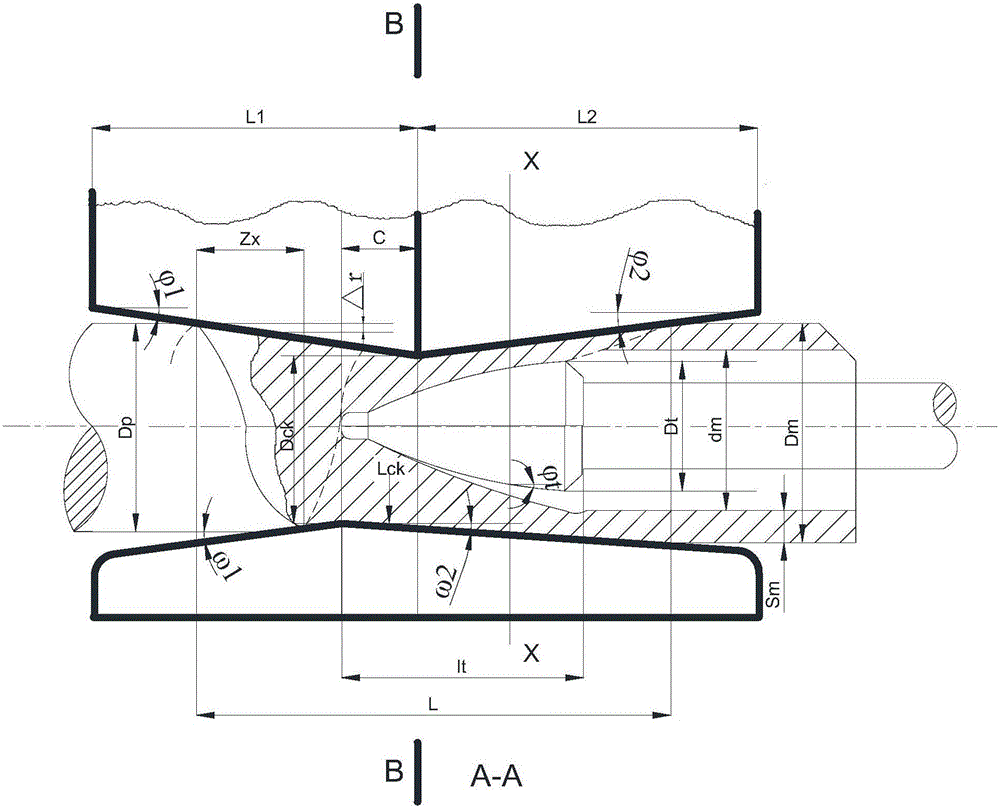

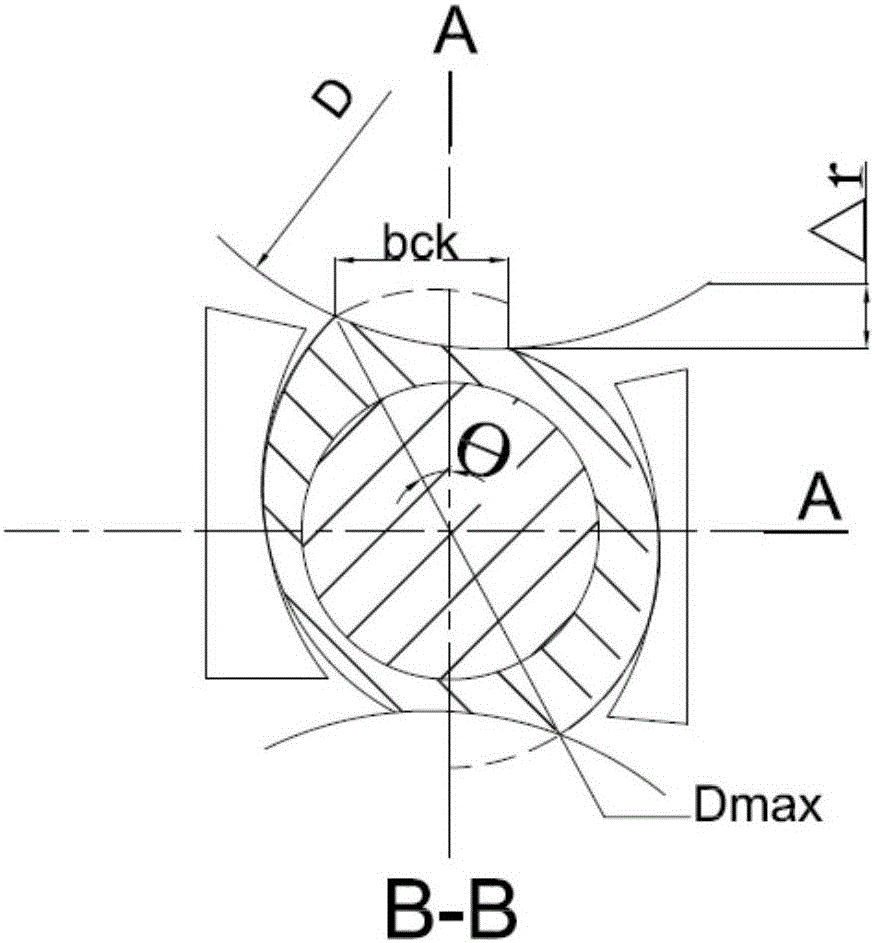

[0087] Taking a φ240mm two-roll skew rolling mill as an example, the billet is a φ50mm round steel, which is rolled into a φ50mm capillary tube.

[0088] Known: D 0 =240mm, L 1 =74.44mm, L 2 =62.00mm, β=15°, γ=15°, D ck0 =43.5mm, L ck0 =51.6mm, L ck1,2 =58.6mm, Z x =18mm, ω 1 = 2°, ω 2 =1.6°, l=2000mm.

[0089] Select five positions, with the center line of rolling as the origin, respectively L 1 =50.8mm, 28.6mm, 0, L 2 = 30mm, 50mm.

[0090] Measure the distance between the rolls D ck They are 47.94mm, 46.00mm, 43.5mm, 46.12mm, 47.87mm respectively.

[0091] Measure the guide plate distance L ck They are 55.19mm, 53.62mm, 51.6mm, 53.24mm, 54.33mm respectively.

[0092] The calculated ellipticity coefficients ξ are 1.15, 1.17, 1.19, 1.15, 1.13, respectively.

[0093] The ellipticity coefficient ξ≥1.12 of the billet at the entrance of the roll, so the billet is biased to one side of the roll, and the offset of the billet at a certain point during the rolling pr...

Embodiment 2

[0100] Taking the φ100mm barrel roll of a certain factory as an example, it is rolled into a φ80*7mm capillary tube;

[0101] Known: D 0 =550mm, D p = 100mm, D m =80mmL 1 = L 2 =81.7mm, β=8°, γ=0°, D ck0 =90mm, L ck0 =99mm, L ck1,2 =121mm, Z x =19mm, l 1 = l 2=180mm, ω 1 = ω 2 =3.5°, l=2000mm.

[0102] Select five positions, with the center line of rolling as the origin, respectively L 1 =70mm,44.3mm,0,L 2 = 30mm, 70mm.

[0103] Measure the distance between the rolls D ck They are 98.56mm, 95.42mm, 90mm, 93.67mm, 98.56mm respectively.

[0104] Measure the guide plate distance L ck They are 107.56mm, 104.42mm, 99mm, 102.67mm, 107.56mm respectively.

[0105] The calculated ellipticity coefficients ξ are 1.09, 1.09, 1.1, 1.1, 1.09 respectively.

[0106] The ellipticity coefficient ξ of the blank at the entrance of the roll is x ·tan ω 1 , the corrected tail wagging amount d x =k·Δd=k·l x ·tan ω 1 , at a distance l from the roll hole throat x Three sets o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com