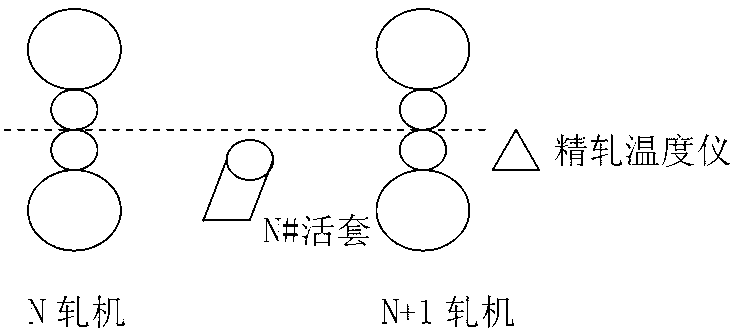

Hot continuous rolling stainless steel strip steel tail portion loop control method

A technology of a stainless steel strip and a control method, applied in the field of hot-rolled strip steel, can solve problems such as the instability of looper tail flick, and achieve the effects of reducing tail flick phenomenon and product quality problems, ensuring movement and reducing influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In this implementation example, the implementation process of the present invention is completely automatically implemented in a computer program.

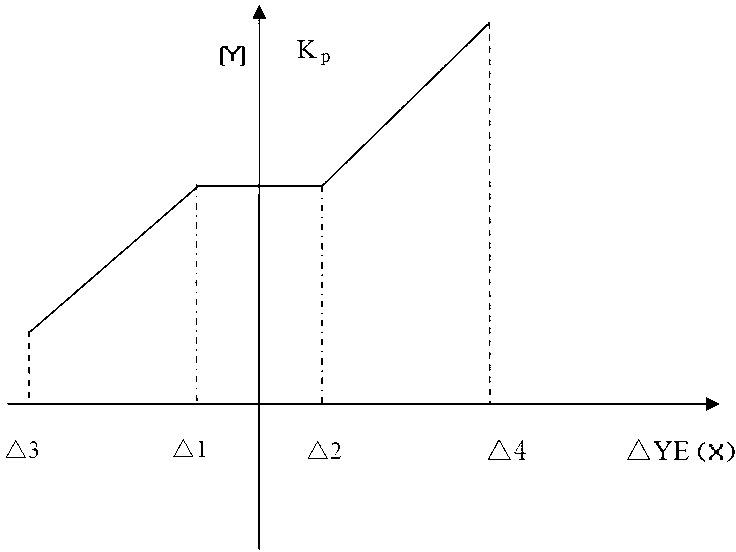

[0032] Step 1, design the broken line, take the torque deviation value of the looper at the end of the strip, that is, the given torque-actual moment, as the X axis, and use the looper torque control coefficient value as the Y axis, establish a plane Cartesian coordinate system, and the broken line is a three-segment linear Equation, the coordinates of the starting point of the first segment are (△3, 1*10 -6 ), the end point coordinates are (△1, 4*10 -6 ), the starting point coordinates of the second segment are (△1, 4*10 -6 ), the end point coordinates are (△2, 4*10 -6 ), the coordinates of the starting point of the third segment are (△2, 4*10 -6 ), the end point coordinates are (△4, 8*10 -6 ), according to the torque deviation value of the specific strip end looper, linearly insert the value in the broken line, and us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com