Continuous rolling mill entrance region tight rolls system and control method thereof

A control method and technology of the entry section, which are applied in the rolling mill control device, metal rolling, tail end control, etc., can solve the problems of great influence on the quality and yield, achieve the protection of the surface of the tension roll, avoid the sliding phenomenon, improve the The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

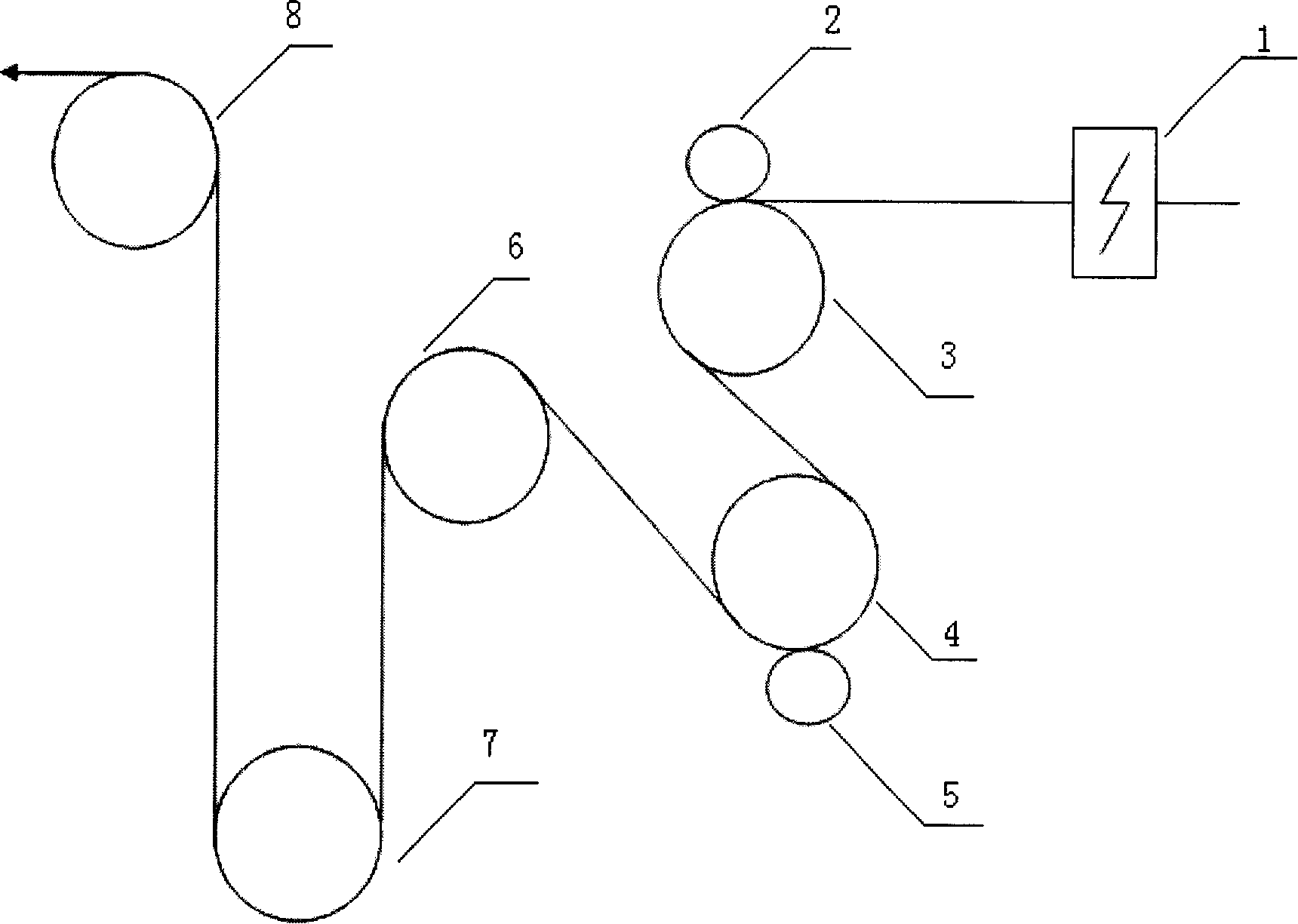

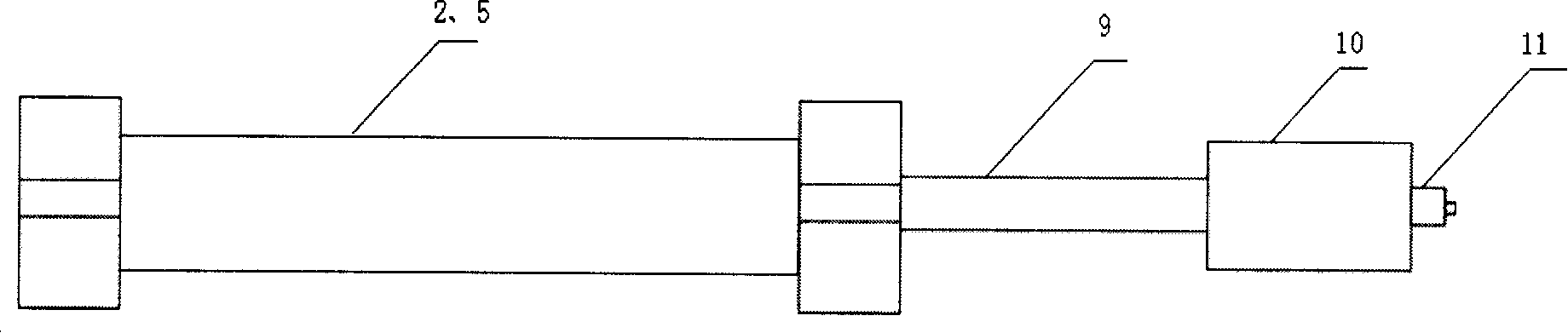

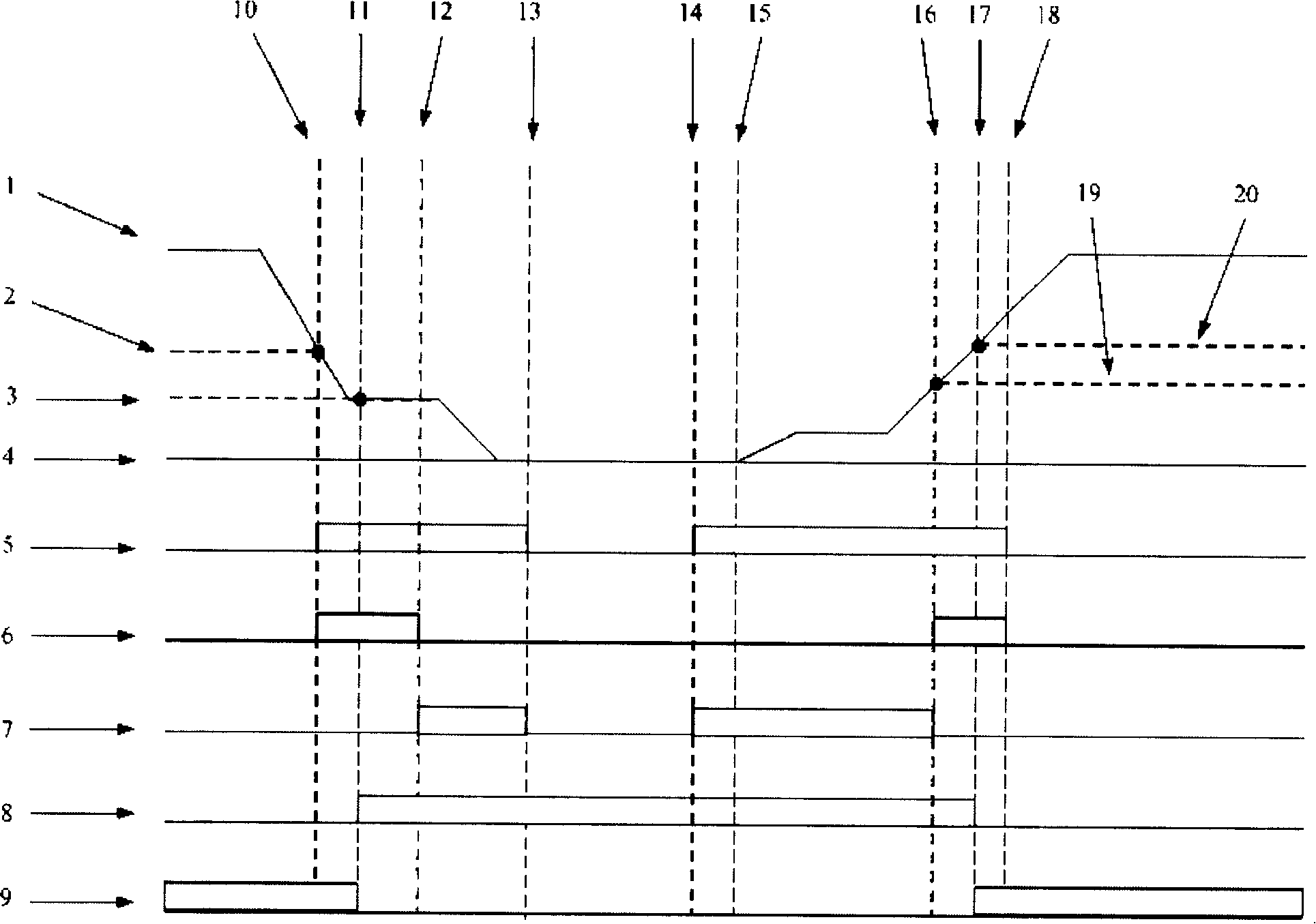

[0028] Depend on figure 1 and figure 2 It can be seen that the tension roller group system of the present invention includes: welding machine 1, 1# pressure roller 2, 1# tension roller 3, 2# tension roller 4, 2# pressure roller 5, 3# tension roller 6, 4# Tension Roller 7, 1# Control Roller 8, Electric Motor 10, Connecting Rod 9, Encoder 11.

[0029] The electric motor 10 is connected to the pressure roller 2 and the pressure roller 5 through the connecting rod 9 to provide torque for the pressure roller 2 and the pressure roller 5, and the electric motor 10 is also connected to an encoder 11 . The present invention uses an electric motor as the power device, and of course other power devices can also be used, and the power device is connected to the control system through the PROFIBUS DP network to control the torque and speed of the pressure roller power device. Adjust the speed and torque of the pressure roller according to the speed, tension of the looper, and the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com