Steel strip tail deviation control method

A control method and strip steel technology, applied in the direction of tail end control, rolling force/roll gap control, etc., can solve the problems of short time passing through the rolling mill, delayed disposal time, fast steel throwing speed, etc., and achieve good control effect, Effect of accidental roll drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

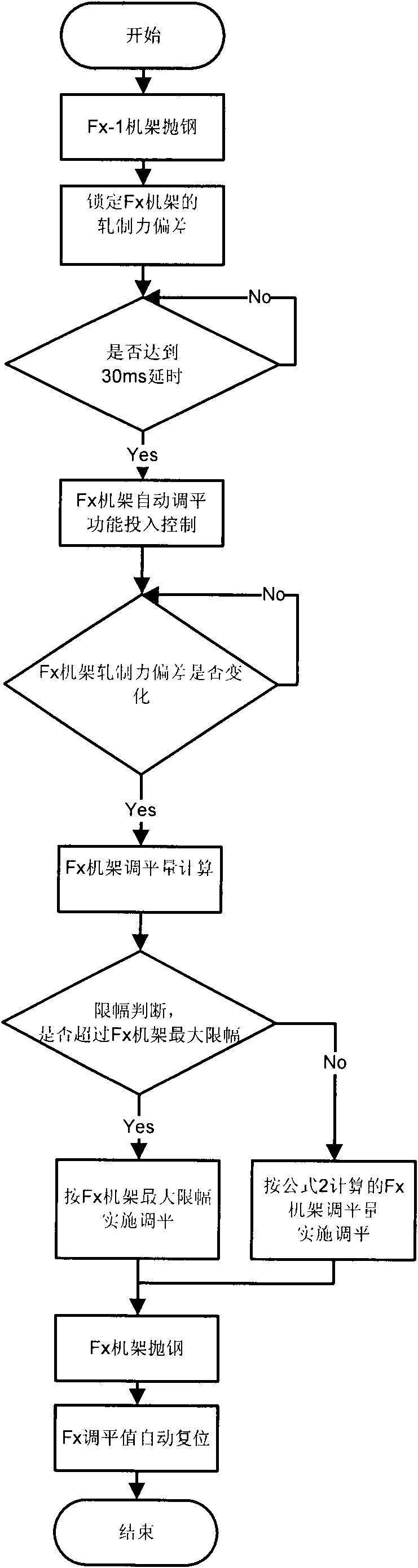

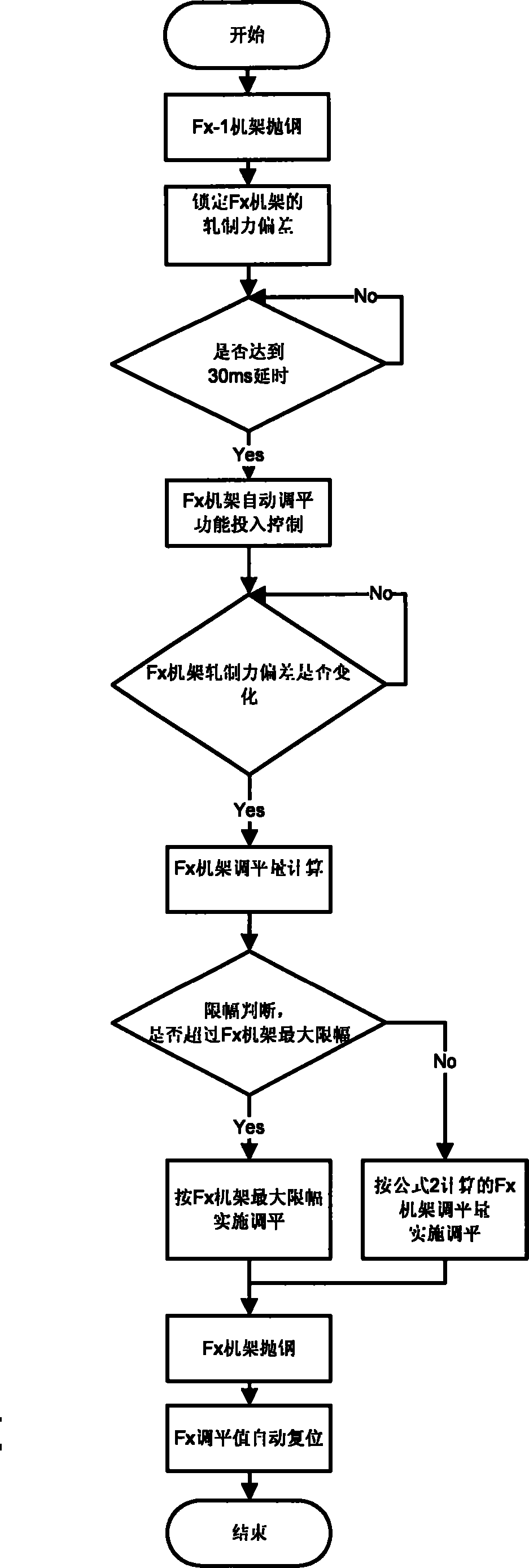

[0047] In this embodiment, taking the finishing mill of the 2050 hot rolling production line used by the inventor as an example, the target thickness of the finished product frame h=2.5mm, the target width of the finished frame w=1173mm, and the target final rolling temperature ft=860°C For strip steel, the rolling mill stiffness coefficient is 1.67um / t. as per figure 2 The flow shown for the F 7 Rack to adjust:

[0048] (1) start;

[0049] (2)F 6 The rolling mill throws steel, and the pressure sensor measures F at this time 7 The rolling force deviation on both sides of the work roll of the rolling mill is 0t, so it is locked as ΔF (DS-OS)LockOn ;

[0050] (3) Judging whether the delay time reaches 30ms, after the delay time reaches the set 30ms, F 7 Rolling mill automatic leveling system put into control;

[0051] (4) According to the F measured in real time by the pressure sensor 7 The rolling force value on both sides of the work roll of the rolling mill, we know...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com