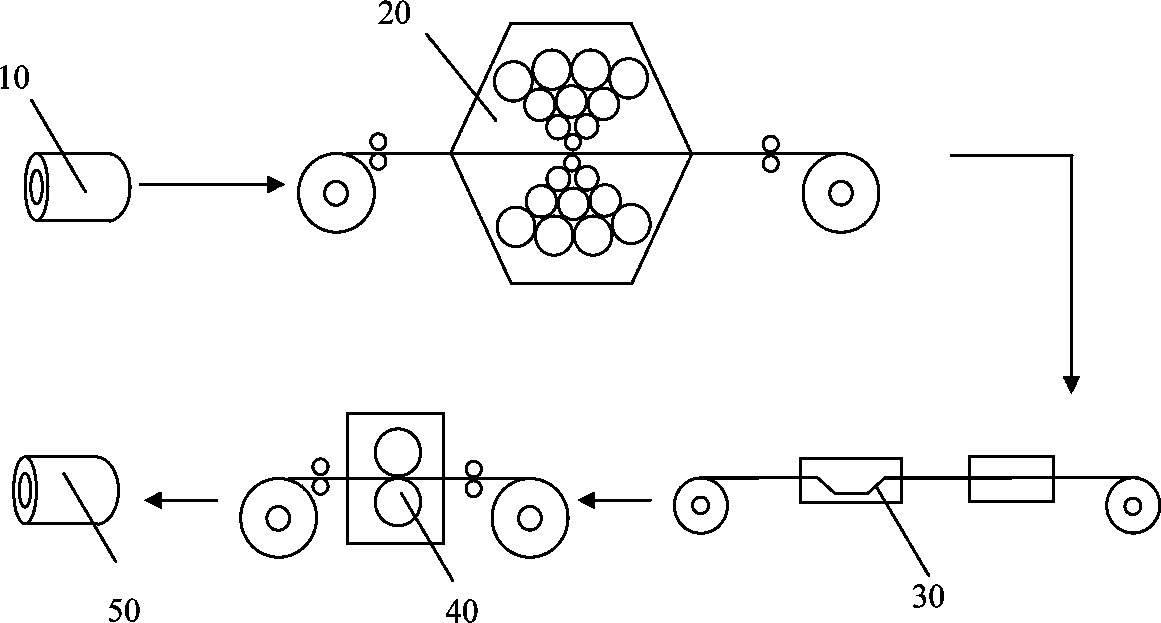

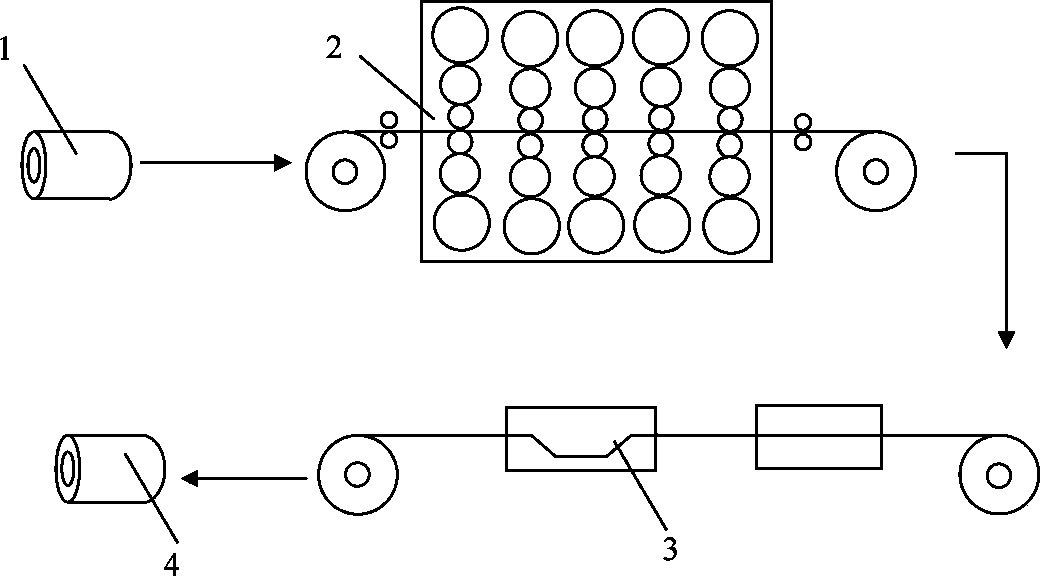

Method for producing ferritic stainless steel bands with roughened surfaces through cold continuous rolling

A technology of stainless steel strip and continuous cold rolling, applied in workpiece surface treatment equipment, metal rolling, metal rolling, etc., can solve the problems of obvious periodicity of surface textured pattern, unsatisfactory textured effect, and reduced yield. , to ensure the mechanical properties of the product, reduce the leveling process, improve the yield and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] When the hot-rolled raw material coil with a thickness of 4.0mm is rolled by a five-stand tandem cold rolling mill, the surface roughness and reduction rate of the work rolls of each stand must be strictly controlled. The working roll width of the rolling mill is 1780mm, the diameter is 450mm, and the maximum rolling force is 27000kN. The work rolls are ground by 80-mesh grinding wheels. The surface roughness of the rolls from the first to the fourth stands are 0.93μm, 0.88μm, 0.72μm and 0.55μm respectively, and the reduction rates of the first to fifth stands are 26.3%, 25.9 %, 22.3%, 20.2%, 3.5%. The grinding roughness of the work rolls of the fifth stand was 1.2 μm. The roughness Ra of the roll after texturing is 3.8 μm, and the number of peaks is 60 peaks / cm. The textured rolls are chrome-plated. The kinematic viscosity (40°C) of the oil-in-water emulsion used is 60mm 2 / s, the oil concentration is 2.3wt%, and the strip is cooled to 90°C after rolling. The exit...

Embodiment 2

[0034] When the hot-rolled raw material coil with a thickness of 3.0mm is rolled by a five-stand tandem cold rolling mill, the surface roughness and reduction rate of the work rolls of each stand must be strictly controlled. The working roll width of the rolling mill is 1780mm, the diameter is 400mm, and the maximum rolling force is 27000kN. The working rolls of the rolling mill are ground by 80-mesh grinding wheels. The surface roughness of the rolls from the first to the fourth stands are 1.04μm, 0.86μm, 0.75μm, and 0.51μm respectively, and the reduction rates of the first to fifth stands are 32.2%, 34.1%, 27.4%, 25.2%, 4.0%. The grinding roughness of the work rolls of the fifth stand was 1.1 μm. The roughness Ra of the roll after texturing is 3.6 μm, and the number of peaks is 71 peaks / cm. The textured rolls are chrome-plated. The kinematic viscosity (40°C) of the emulsion used is 70mm 2 / s, the concentration is 4.1wt%, and the strip is cooled to 95°C after rolling. Th...

Embodiment 3

[0036]When the hot-rolled raw material coil with a thickness of 6.0mm is rolled by a five-stand tandem cold rolling mill, the surface roughness and reduction rate of the work rolls of each stand must be strictly controlled. The working roll width of the rolling mill is 1420mm, the diameter is 300mm, and the maximum rolling force is 23000kN. The work rolls of the rolling mill are ground by 80-mesh grinding wheels. The surface roughness of the rolls from the first to the fourth stands are 1.21 μm, 0.91 μm, 0.73 μm, and 0.43 μm respectively, and the reduction rates of the first to fifth stands are 33.3%, 22.5%, 16.1%, 15.4%, 9.1%. The grinding roughness of the work rolls of the fifth stand was 1.2 μm. The roughness Ra of the roll after texturing is 3.8 μm, and the number of peaks is 58 peaks / cm. The textured rolls are chrome-plated. The kinematic viscosity (40°C) of the emulsion used is 95mm 2 / s, the concentration is 8.3wt%, and the strip is cooled to 120°C after rolling. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com