Roll profile design method for hot rolling skin pass mill based on multi-segment roll profile curve fitting

A technology of roll shape curve and design method, applied in the direction of contour control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with specific embodiment, the present invention will be further described:

[0052] Aiming at the serious wear problem of the work rolls in the tempering machine of a hot rolling production line in a factory, the roll profile of the work rolls was improved.

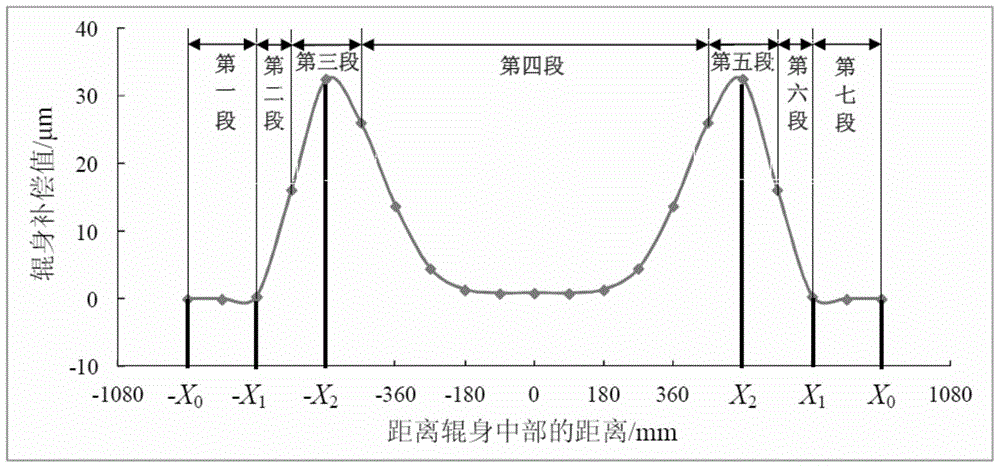

[0053] According to the content of the present invention, the corresponding work roll profile curve is designed.

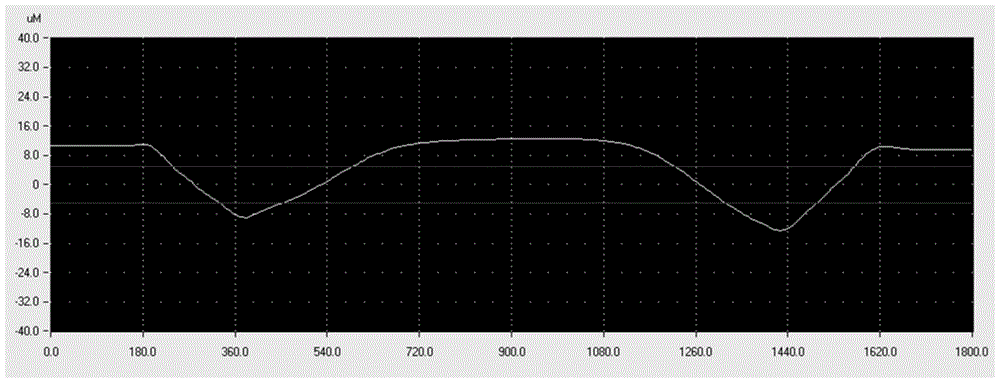

[0054] First of all, the wear data of the work rolls of the tempering machine in the factory was counted in the past half month, a total of 23 sets of data, see Figure 4 , calculate the average value of wear at each position along the roll body, and obtain the wear trend diagram of the work roll, see Figure 5 .

[0055] According to the wear trend curve to calculate the compensation value of the roll shape of the work roll, it is first necessary to compensate the unworn part of the wear curve to a horizontal straight line, and then calculate the compensation value of each point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com