Multi-rack working roll shifting method for eliminating local high points of plate strip

A technology of local high points and work rolls, applied in the direction of profile control, etc., can solve the problems of wear groove inheritance, etc., and achieve the effect of improving roll wear, eliminating local high points, and weakening heredity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

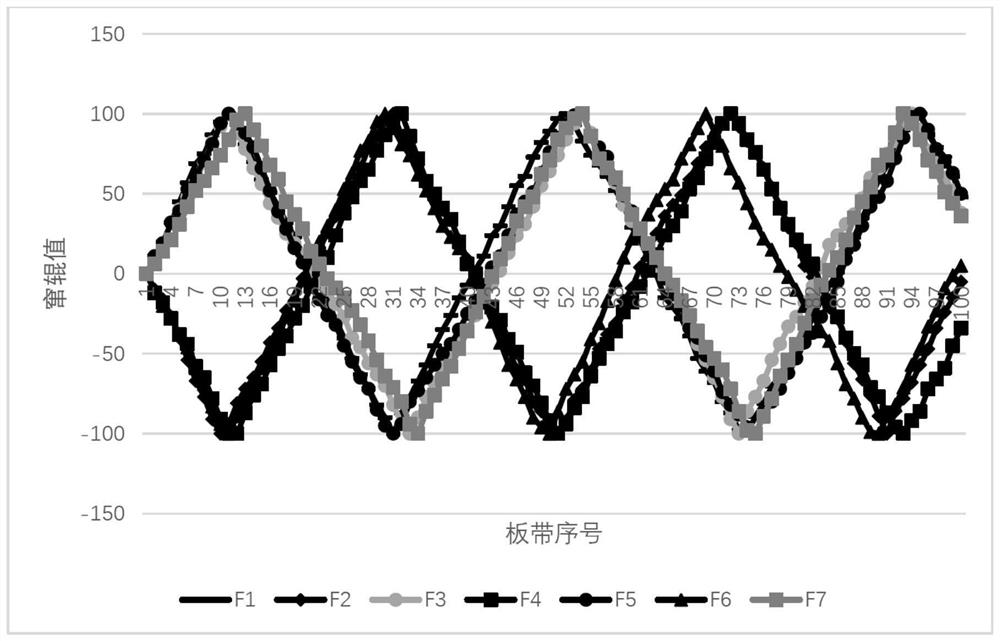

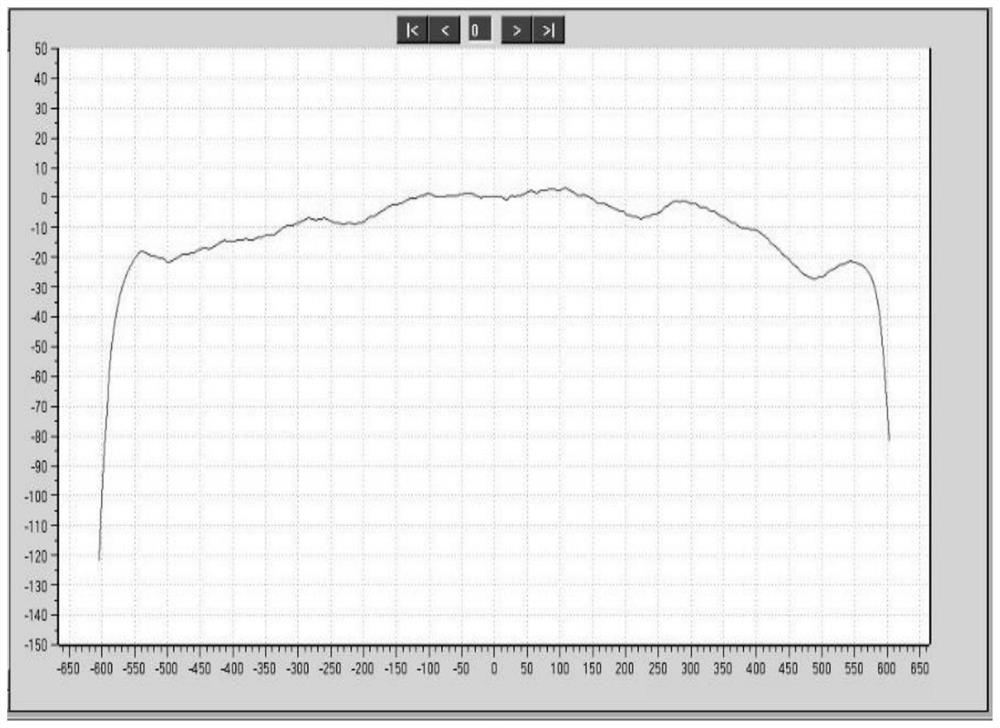

[0033] When the rolling kilometers of the finishing mill are long, the uneven wear of the rolls in the later stage of rolling is serious, and there are obvious local high points on the edge of the strip at the exit of the finishing rolling, which deteriorates the quality of the section profile of the strip. This embodiment provides a multi-stand work roll shifting method that eliminates local high points of strips, improves roll wear, and extends rolling kilometers. include:

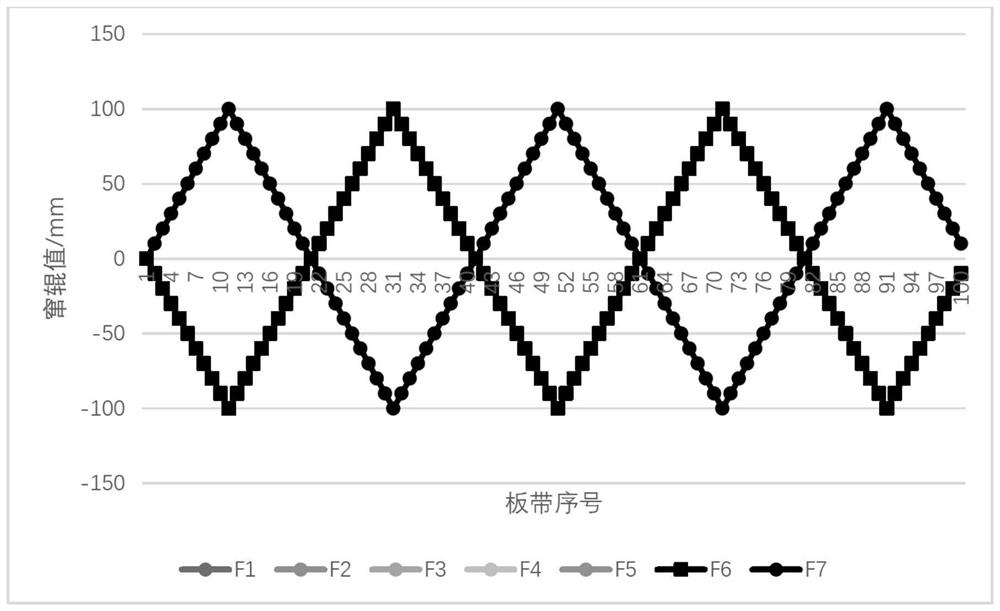

[0034] During the rolling process, each stand moves back and forth periodically with a certain step length and direction crossing; among them, the periodic step size is a fixed value; when the rolling starts, the initial rolling direction of the adjacent stands is diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com