A Soil Automatic Sampling Mechanism for Engineering Survey Based on Magnetic Control

A technology of magnetic control and automatic sampling, applied in sampling devices and other directions, can solve the problems of time-consuming, labor-intensive, complicated operation, etc., and achieve the effect of convenient use and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

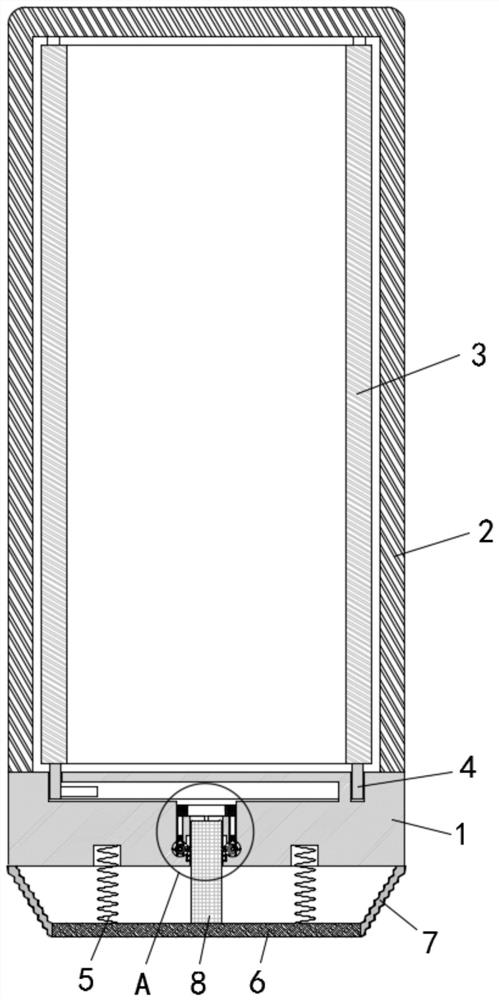

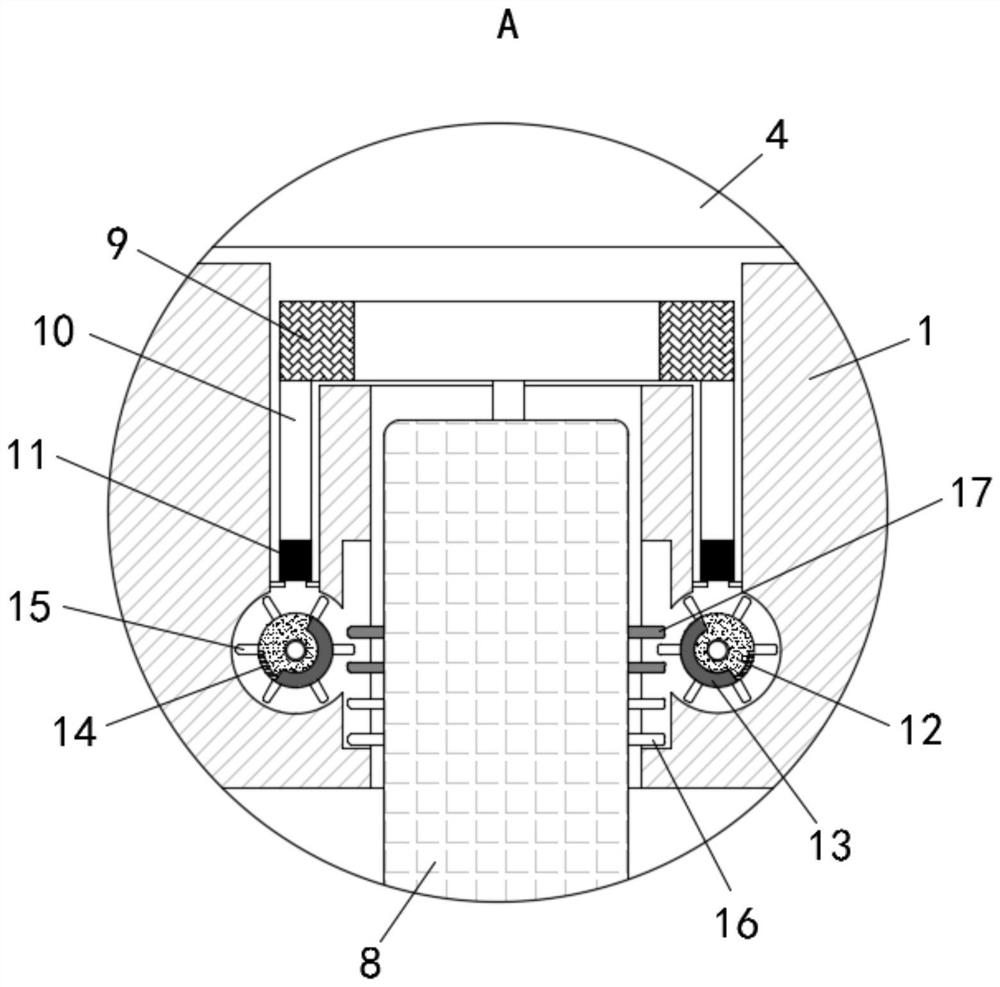

[0027] as attached figure 1 to attach Figure 4 Shown:

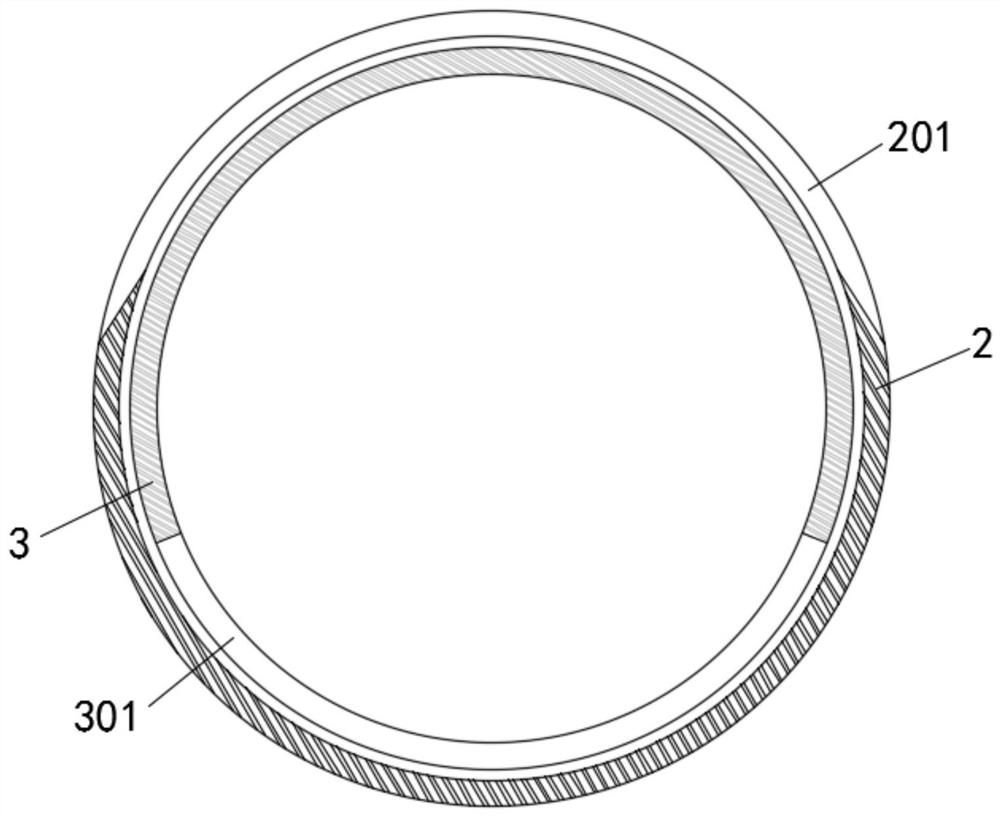

[0028] The present invention provides a soil automatic sampling mechanism for engineering survey based on magnetic force control, comprising a base 1, the top of the base 1 is fixedly connected with an outer cylinder 2, the side wall of the outer cylinder 2 is provided with a sampling port 201, the top of the base 1 is The inner cylinder 3 is rotatably connected to the inside of the outer cylinder 2. There is a gap 301 on the side wall of the inner cylinder 3. The inner cylinder 3 is installed on the base 1 through the support ring 4. The bottom of the base 1 is connected to the detection plate through the compression spring 5. 6. The outside of the detection board 6 is covered with an elastic protective layer 7 connected to the base 1. The top of the detection board 6 is fixedly connected with a guide post 8 inserted into the base 1. The inside of the base 1 slides above the guide post 8 A lifting ring 9 is plugged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com