Systems and methods for cyclic operations in a fuel synthesis process

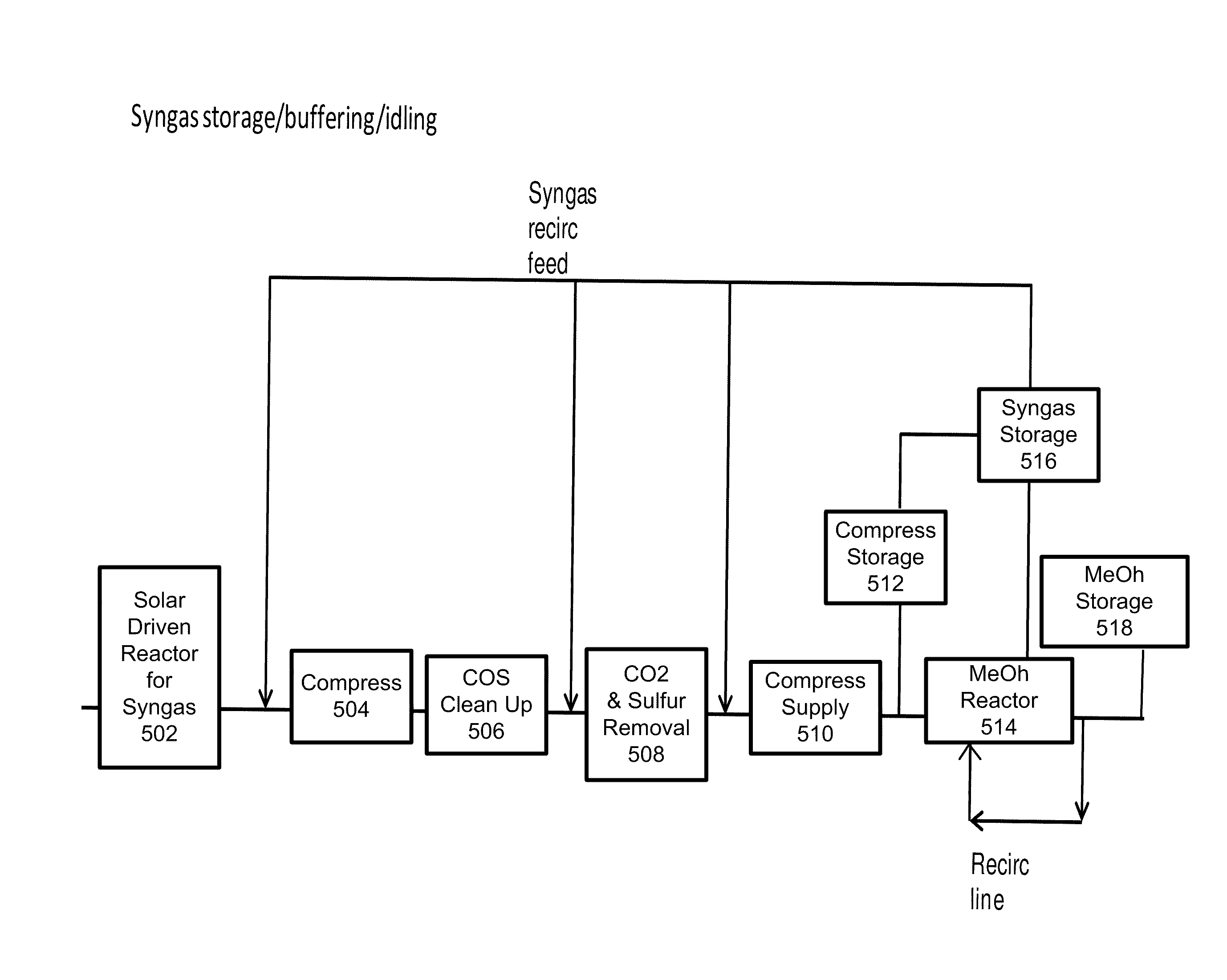

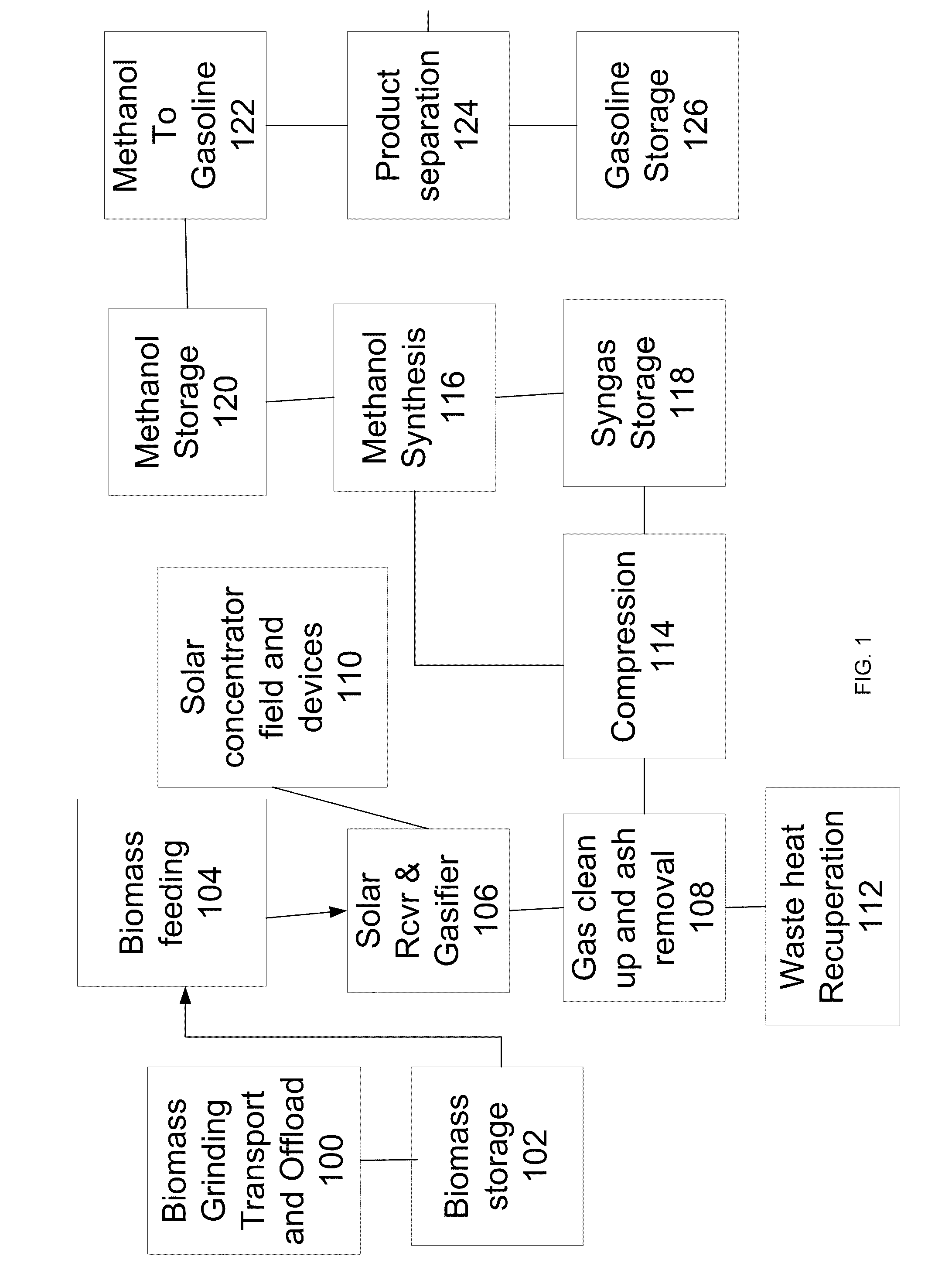

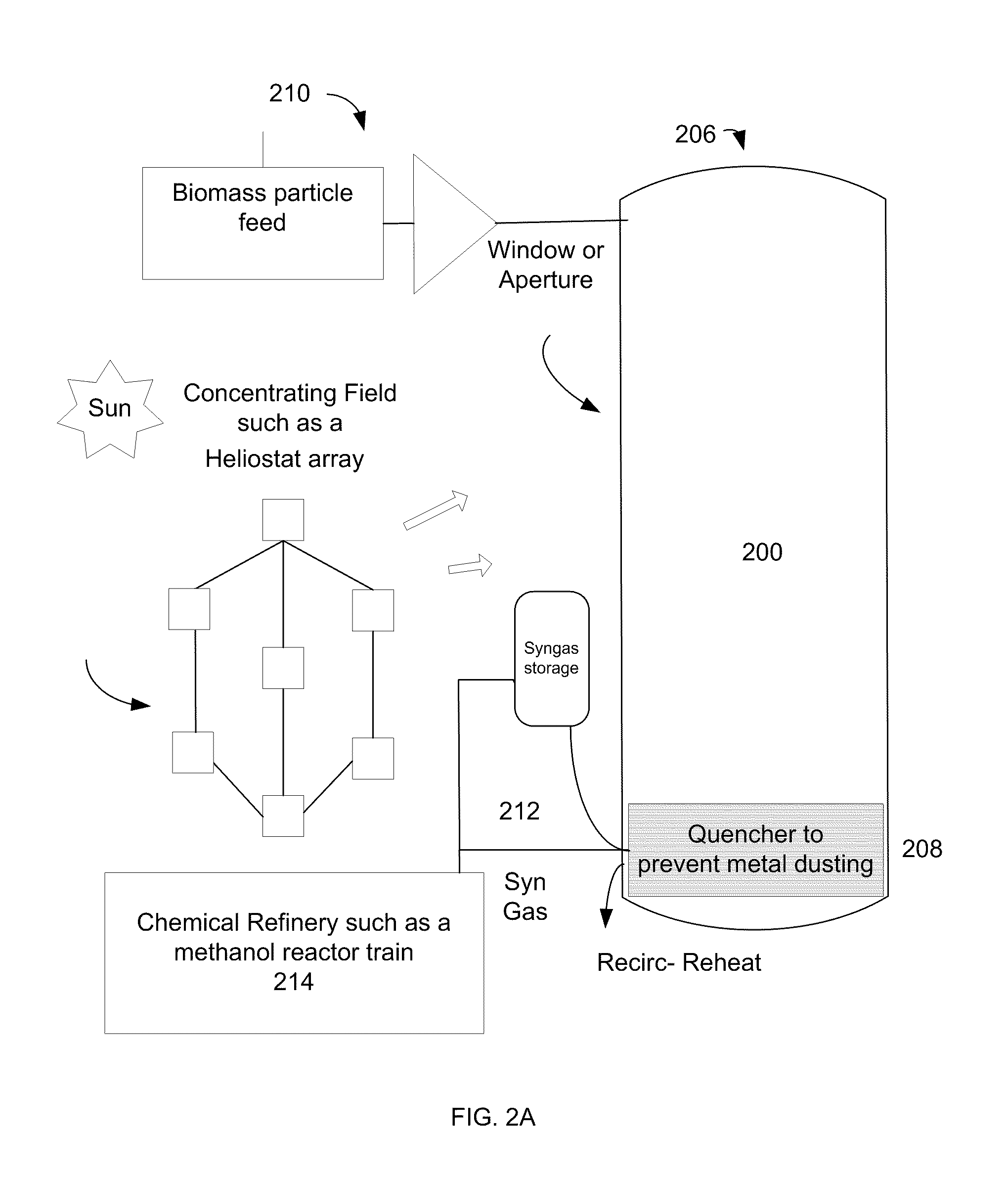

a fuel synthesis and cyclic operation technology, applied in the field of solar-driven systems, methods and apparatus for refining biomass and other materials, can solve the problems of limited conversion and still lower yield, and achieve the effect of increasing the output of a train, and rapid and efficient reactor cycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]In the following description, numerous specific details are set forth, such as examples of specific data signals, named components, connections, number of reactor tubes, etc., in order to provide a thorough understanding of the present invention. It will be apparent, however, to one of ordinary skill in the art that the present invention may be practiced without these specific details. In other instances, well known components or methods have not been described in detail but rather in a block diagram in order to avoid unnecessarily obscuring the present invention. Further, specific numeric references such as first reactor tube, may be made. However, the specific numeric reference should not be interpreted as a literal sequential order but rather interpreted that the first reactor tube is different from a second reactor tube. Thus, the specific details set forth are merely exemplary. The specific details may be varied from and still be contemplated to be within the spirit and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com