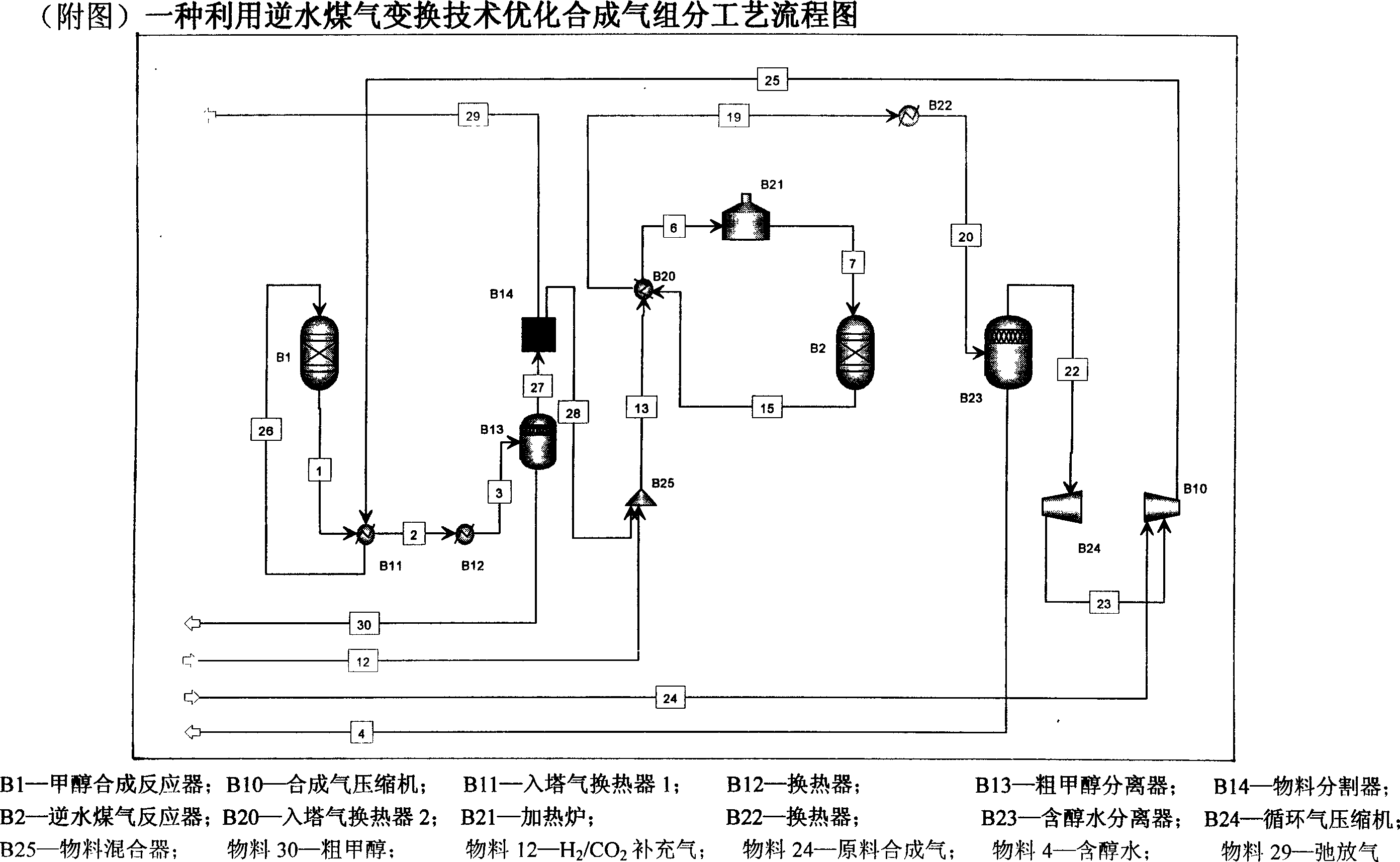

Method for optimization of synthetic gas components by reversed water-gas shift reaction technology and flow therefor

A technology of reverse water gas and synthesis gas, which is applied in the fields of petroleum, coal and natural gas chemical industry, and can solve the problems of uneconomical production of synthesis gas, large circulation volume and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] When using natural gas as raw material to produce methanol, dimethyl ether, and liquid hydrocarbons (GTL) and other products, it is necessary to first undergo the steam reforming reaction of natural gas to prepare H 2 , CO, CO 2 Synthesis gas with equal components, and then use this synthesis gas to further synthesize methanol, dimethyl ether, liquid hydrocarbons (GTL) and other products.

[0009] Due to the limitations of synthesis gas manufacturing technology and process, the composition of the prepared synthesis gas often does not meet the ideal requirements for the raw material gas in the subsequent synthesis process. For methanol synthesis, its hydrogen-carbon ratio coefficient R value [R=(H 2 -CO 2 ) / (CO+CO 2 )] is required to be excellent in the range of 2.05 to 2.15, and it meets the requirements of CO 2 The CO content is required to be as high as possible under the condition that the concentration is not lower than 5% (vol), and the synthesis gas produced b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com