Conversion of carbonaceous materials to synthetic natural gas by pyrolysis, reforming, and methanation

a carbonaceous material and carbonaceous technology, applied in the direction of combustible gas production, combustible gas purification/modification, sustainable manufacturing/processing, etc., can solve the problems of low efficiency, limited resource and limited resource of the inability to effectively supply electric power from direct combustion of woody biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

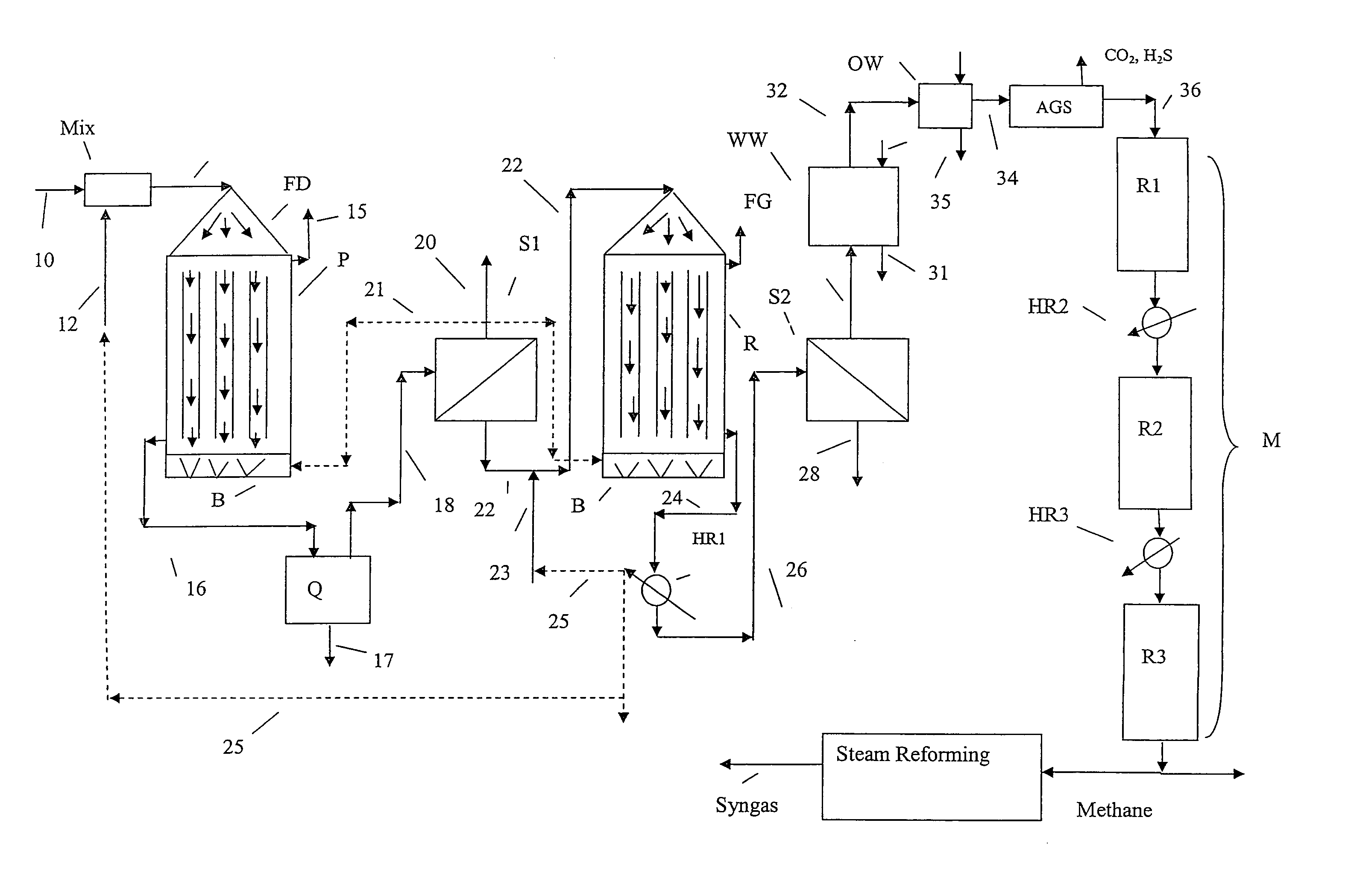

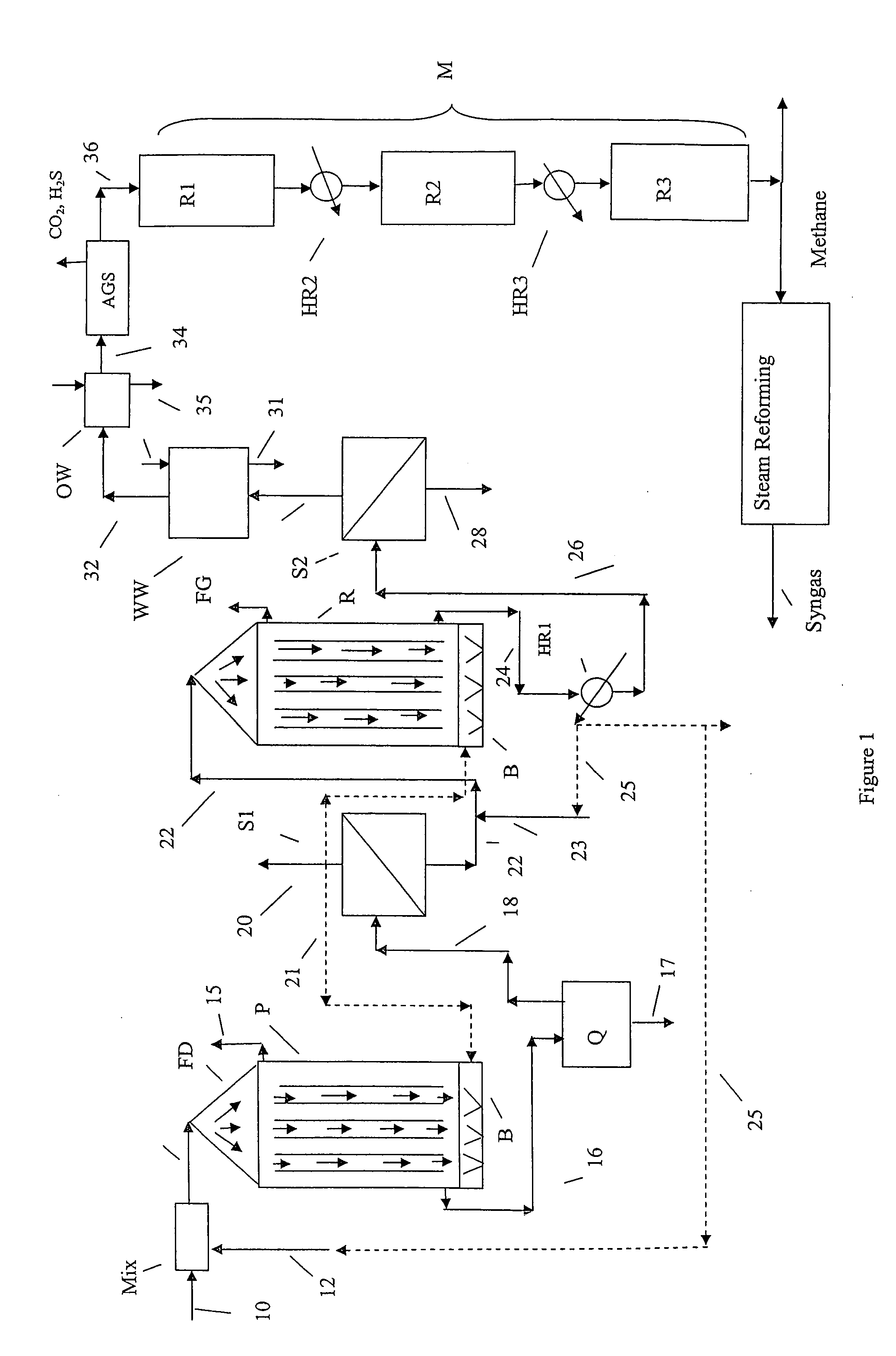

[0022]The present invention is directed to the production of synthetic natural gas (predominantly methane) from carbonaceous materials, preferably biomass materials. Synthetic natural gas, also sometimes called “green gas” is a renewable gas from biomass with natural gas specifications. Therefore, it can be transported through the existing gas infrastructure, substituting for natural gas in all existing applications. Another advantage of green gas is that is carbon neutral. That is, using biomass as an energy supply will typically not result in a net CO2 emission since its source can be replanted and uses CO2 from the atmosphere during its growth period.

[0023]While this invention is applicable to a broad range of carbonaceous feedstocks including the traditional naturally occurring solid fossil fuels such as coal, peat, lignite, tar sands, and bitumen from oil shale, the preferred feedstocks for use in the present invention are biomass feedstocks Non-limiting examples of biomass fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com