Environmentally-friendly marine antifouling coating and preparation method thereof

A marine antifouling and coating technology, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of marine biological environmental impact, practical application and considerable distance, copper compound deposition, etc. , achieve good bactericidal and antibacterial effects, protect the environment, and prevent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

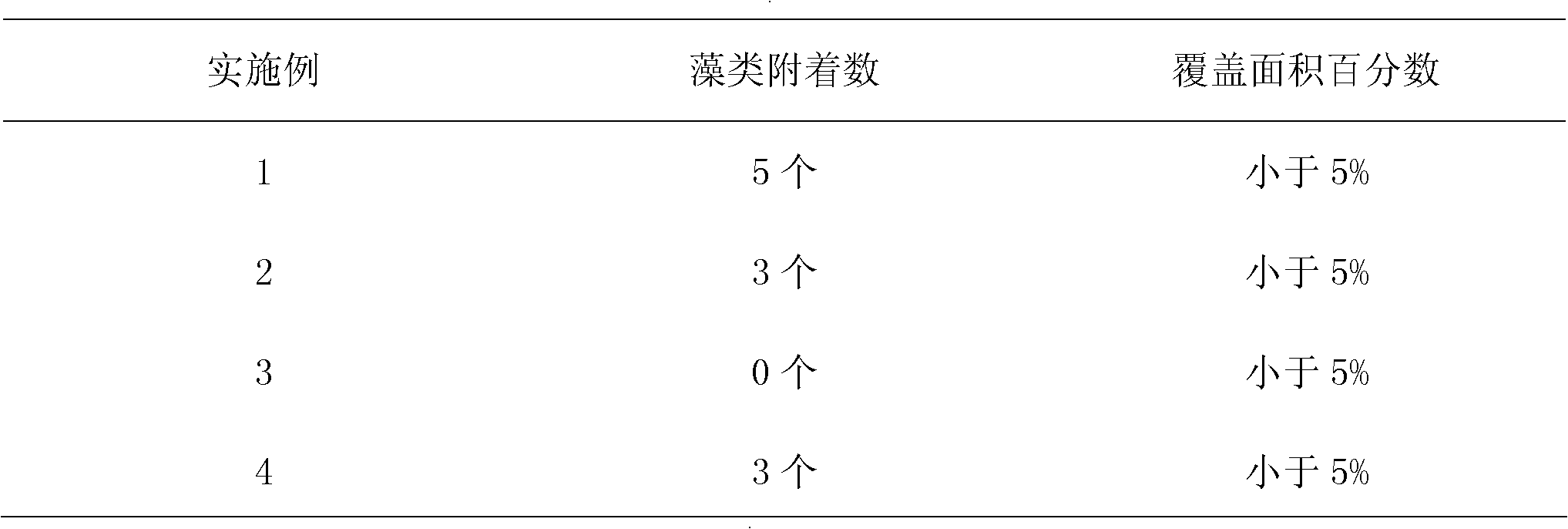

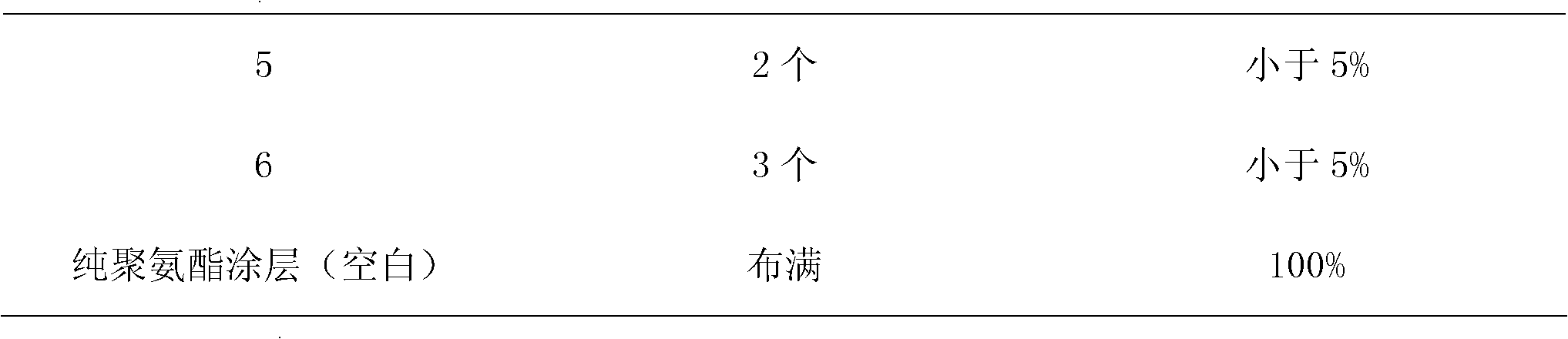

Examples

Embodiment 1

[0043] Example 1 Preparation of coating with nano silver content of 0.03%

[0044] The formula for component A is as follows:

[0045] Silica 8kg

[0046] 3-(2,3 glycidoxy)propyltrimethoxysilane 20kg

[0047] Silicone modified acrylic resin (Jiangsu Sanmu resin company, model SM1057) 400kg

[0048] Xylene 180kg

[0049] Rosin 17kg

[0050] Nano silver solution 1% solution 33 kg

[0051] Copper pyrithione 35kg

[0052] Zinc oxide 180kg

[0053] Iron oxide red 150kg

[0054] The formulation of Part B is as follows:

[0055] Polyamide resin (Jiangsu Sanmu resin company, model 650) 40 kg

[0056] γ-Aminopropyltriethoxysilane 30kg

[0058] Preparation method: add 400 kg of organosilicon modified acrylic resin, 8 kg of silicon dioxide, 180 kg of zinc oxide, 150 kg of iron red, 35 kg of copper pyrithione, and 100 kg of thinner into a paint mixing tank, high speed 1200 rpm , dispersed for 30 minutes. After sanding to a fineness of less than 50 m...

Embodiment 2

[0060] Example 2 Preparation of coating with nano silver content of 0.06%

[0061] The formula for component A is as follows:

[0062] Silica 8kg

[0063] Vinyltris(β-methoxyethoxy)silane 22kg

[0064] Silicone modified acrylic resin (DS-502 resin produced by Shandong Dongming Petrochemical Group) 500kg

[0065] Cyclohexanone 100kg

[0066] Zinc pyrithione 50kg

[0067] Rosin 30kg

[0068] Nano silver solution 1% solution 65kg

[0069] Zinc oxide 125kg

[0070] Iron oxide red 100kg

[0071] The formulation of Part B is as follows:

[0072] Polyamide resin (Jiangsu Sanmu resin company, model 650) 60 kg

[0073] γ-Aminopropyltriethoxysilane 20kg

[0074] Xylene 20kg

[0075] Preparation method: add 500 kg of organosilicon modified acrylic resin, 10 kg of silicon dioxide, 125 kg of zinc oxide, 100 kg of iron red, 50 kg of zinc pyrithione, and 60 kg of thinner into the paint mixing tank, high speed 1200 rpm , dispersed for 30 minutes. After sanding until the fineness ...

Embodiment 3

[0077] Example 3 Preparation of coatings with a nano-silver content of 0.09%

[0078] The formula for component A is as follows:

[0079] Silica 10kg

[0080] Gamma-(methacryloyloxy)propyltrimethoxysilane 30kg

[0081] Silicone modified acrylic resin (Jiangsu Sanmu Resin Co., Ltd., model SMH-30) 600 kg

[0082] Xylene 100kg

[0083] Rosin 24kg

[0084] Nano silver solution 3% solution 31 kg

[0085] Zinc pyrithione 36kg

[0086] Zinc oxide 105kg

[0087] Iron oxide red 100kg

[0088] The formulation of Part B is as follows:

[0089] Polyamide resin (Jiangsu Sanmu Resin Co., Ltd., model 651) 70 kg

[0090] Thinner Xylene 30kg

[0091] Preparation method: add 600 kg of organosilicon modified acrylic resin, 10 kg of silicon dioxide, 125 kg of zinc oxide, 100 kg of iron red, 20 kg of pyridine sulfur copper silver, and 40 kg of thinner into the paint mixing tank, high speed 1200 rpm , dispersed for 30 minutes. After sanding until the fineness is less than 50 microns, af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com