Anti-corrosion anti-dirt method or biological anti-dirt and conductive anti-dirt combination

A biological antifouling, combined technology, applied in conductive coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problem of reduced volume conductivity, short average service life, and conductive carbon black easily migrated to the surface. and other problems, to achieve the effect of high electrical conductivity and lasting and stable electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

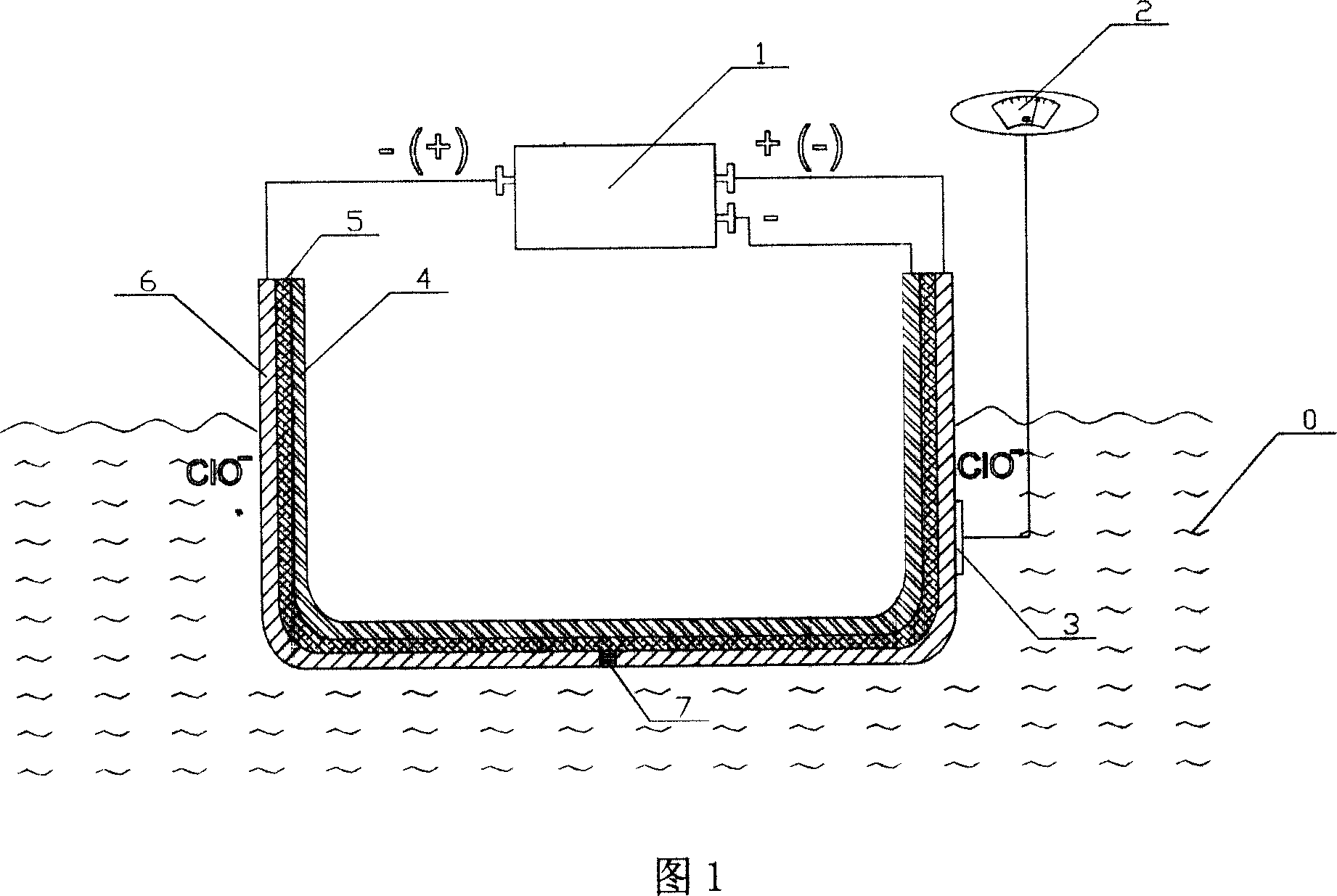

Image

Examples

Embodiment 1

[0024] 1) Preparation of bio-antifouling coating: 15g of chlorinated rubber is stirred and mixed in 10g of xylene, after dissolving, add 4g of nano-titanium dioxide, 4g of calcium hydroxide, 1g of ethyl butyrate, 12.5g of chlorinated paraffin, and stir for 2 hours , add 3.5g tannin, process 6 hours with ball mill, after stirring again 2 hours, make biological antifouling coating;

[0025] 2) Preparation of conductive antifouling paint: 24g of chloroether resin and 30g of xylene were mixed, 1g of ethyl glycerate and 20g of chlorinated paraffin were added, mechanically stirred evenly, then 1g of polyaniline, 3g of dodecylbenzenesulfonic acid, 8g nano-titanium dioxide, 12g bentonite and 1g titanate coupling agent, stir vigorously for 1 hour; ultrasonically treat the mixture for 10 minutes, and then process it with a ball mill or colloid mill for 1 hour; under high-speed stirring, mix the mixture thoroughly for 1 hour , to obtain a conductive antifouling coating;

[0026] 3) the ...

Embodiment 2

[0028] 1) Preparation of bio-antifouling coating: Stir and mix 9g chloroether resin in 25g xylene, after dissolving, add 4g nanometer titanium dioxide, 6g bentonite, 0.5g ethyl butyrate, 3g chlorinated paraffin, after stirring for 2 hours, add 2.5g of tannin was processed with a ball mill for 1 hour, and after stirring for 2 hours, a biological antifouling coating was obtained;

[0029] 2) Preparation of conductive antifouling paint: Mix 20g of polyurethane and 60g of xylene, add 2g of ethyl glycerate and 2g of dioctyl phthalate, stir evenly, then add 5g of polyaniline, 1g of salicylic acid, 3g of nano Titanium dioxide, 5g calcium hydroxide and 2g titanate coupling agent, stirred vigorously for 3 hours; ultrasonically treated the mixture for 1 hour, and then added it with a ball mill or colloid mill for 2 hours; under high-speed stirring, the mixture was fully mixed for 4 hours , to obtain a conductive antifouling coating;

[0030] 3) Apply the biological antifouling coating ...

Embodiment 3

[0032]1) Preparation of bio-antifouling coating: 16g of chlorinated rubber was stirred and mixed in 18g of xylene. After dissolving, 1.5g of nano-titanium dioxide, 0.8g of methyl silicone oil, and 6.2g of chlorinated paraffin were added. After stirring for 2 hours, 7.5g of chlorinated rubber was added. Tannin was processed with a ball mill for 2 hours, and after stirring for 2 hours, a biological antifouling coating was obtained;

[0033] 2) Preparation of conductive antifouling coating: mix 28g of chloroether resin and 40g of xylene, add 0.8g of ethyl glyceride and 6g of chlorinated paraffin, stir evenly, then add 10g of polyaniline, 5g of methanesulfonic acid, 2g of nano Titanium dioxide, 3g bentonite and 5.2g titanate coupling agent were stirred vigorously for 6 hours; the mixture was ultrasonically treated for 3 hours, and then processed with a ball mill or colloid mill for 4 hours; under high-speed stirring, the mixture was fully mixed for 8 hours, Obtain conductive antif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com