Synthesis technology of zinc acrylate or copper acrylate self-polishing anti-fouling resin

A technology of copper acrylate and zinc acrylate, used in antifouling/underwater coatings, paints containing biocides, etc., can solve the problems of poor controllability of resin structure and complex process, and achieve shortened reaction time, optimized synthesis process, and improved production efficiency. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The zinc acrylate self-polishing antifouling resin synthesis process of the present embodiment comprises the following steps:

[0027] a. Preparation of Zinc Acrylate Small Molecule Monomer

[0028] Add 80g of propylene glycol methyl ether and 49.5g of zinc hydroxide into a four-necked flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel, and thermometer, stir and heat up to 80°C, then weigh 36g of acrylic acid, 61g of benzene The mixture of formic acid and 130 g of propylene glycol methyl ether was added dropwise at a constant speed for 1.5 hours through a constant pressure dropping funnel, and the stirring was continued for 1 hour to obtain a colorless and transparent solution of zinc acrylate monomer.

[0029] The solid content of the above-mentioned colorless transparent solution was measured to be 41%.

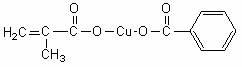

[0030] The structural formula of the obtained zinc acrylate monomer can be expressed as follows:

[0031]

[0032] b. Preparati...

Embodiment 2

[0036] The copper acrylate self-polishing antifouling resin synthesis process of the present embodiment comprises the following steps:

[0037] a. Preparation of Copper Acrylate Small Molecule Monomer

[0038] Add 80g of propylene glycol methyl ether and 49g of copper hydroxide into a four-neck flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel, and thermometer, stir and heat up to 80°C, then weigh 43g of methacrylic acid, 61g The mixture of benzoic acid and 130g propylene glycol methyl ether was added dropwise at a constant speed for 1.5 hours through a constant pressure dropping funnel, and the stirring was continued for 1 hour to obtain a colorless transparent solution of copper acrylate monomer.

[0039] The solid content of the above-mentioned colorless transparent solution was measured to be 43%.

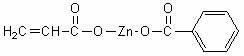

[0040] The structural formula of the obtained copper acrylate monomer can be expressed as follows:

[0041]

[0042] b. Preparation of co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com