Preparation and application of zinc acrylate-type self-polishing matrix resin for antifouling coating

A technology of self-polishing resin and antifouling paint, applied in antifouling/underwater paints, coatings, paints containing biocides, etc. The effect of prolonging the antifouling period, simple and convenient construction and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

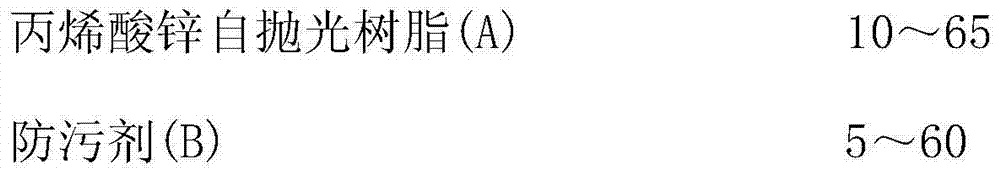

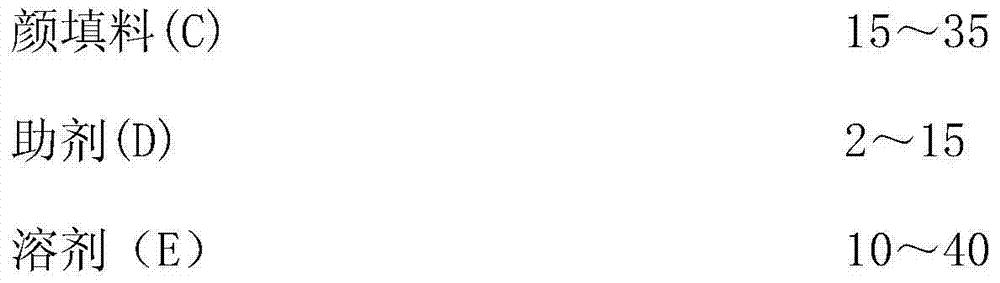

Image

Examples

preparation example Construction

[0031] a. Preparation of zinc acrylate small molecule monomer (a1)

[0032] Add a stoichiometric amount of solvent and zinc oxide or zinc hydroxide into a four-necked flask equipped with a stirring device, condenser, dropping funnel, and thermometer. The temperature is increased to 70~90℃, and one saturated organic acid and the other Unsaturated organic carboxylic acid and a certain amount of deionized water are mixed uniformly according to the metering ratio, and added dropwise to a four-neck bottle, dripping for 2 to 3 hours, and then keep warm until the mixture is clear and transparent, cool down and discharge, add solvent , Controlling the solid content of the zinc acrylate small molecule monomer at 30-55% to obtain the zinc acrylate small molecule monomer (a1) of the present invention.

[0033] In the process of preparing zinc acrylate small molecule monomer (a1), the molar ratio of zinc oxide or zinc hydroxide to a saturated organic acid and another unsaturated organic carbox...

Embodiment 1

[0046] a. Zinc acrylate small molecule monomer a1-1

[0047] In a four-necked flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, add 200 parts of propylene glycol methyl ether and 81.4 parts of zinc oxide under stirring, and heat to 80°C. A mixture of 86.1 parts of methacrylic acid, 74.1 parts of propionic acid, and 20 parts of water was dropped from the dropping funnel for 3 hours. Keep warm until the mixture is clear and transparent. The temperature was lowered and 40 parts of propylene glycol methyl ether were added to prepare the zinc acrylate small molecule monomer a1-1. The measured solid content of a1-1 is 44.6%.

[0048] b. Acrylic zinc self-polishing resin A-1

[0049] In a four-neck flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, add 25 parts of propylene glycol methyl ether, 70 parts of xylene and 5 parts of ethyl acrylate under stirring, and heat to 100°C. A mixed liquid composed of 35 pa...

Embodiment 2

[0051] a. Zinc acrylate small molecule monomer a1-2

[0052] In a four-necked flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, add 200 parts of propylene glycol methyl ether and 81.4 parts of zinc oxide under stirring, and heat to 80°C. A mixture of 72.1 parts of acrylic acid, 74.1 parts of propionic acid, and 20 parts of water was dropped from the dropping funnel for 3 hours. Keep warm until the mixture is clear and transparent. The temperature is lowered, and 20 parts of propylene glycol methyl ether are added to prepare the zinc acrylate small molecule monomer a1-2. The measured solid content of a1-2 is 44.8%.

[0053] b. Acrylic zinc self-polishing resin A-2

[0054] In a four-neck flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, add 25 parts of propylene glycol methyl ether, 70 parts of xylene and 5 parts of ethyl acrylate under stirring, and heat to 100°C. From the dropping funnel, add 20 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com