Preparation method of chickpea peptides

The technology of chickpea peptide and chickpea is applied in the field of preparation of chickpea peptide, which can solve the problems of cumbersome processing technology, labor consumption of equipment investment, potential safety hazard and environmental pollution, etc., and achieves simple process operation, yield and purity. Enhanced, easy protease hydrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

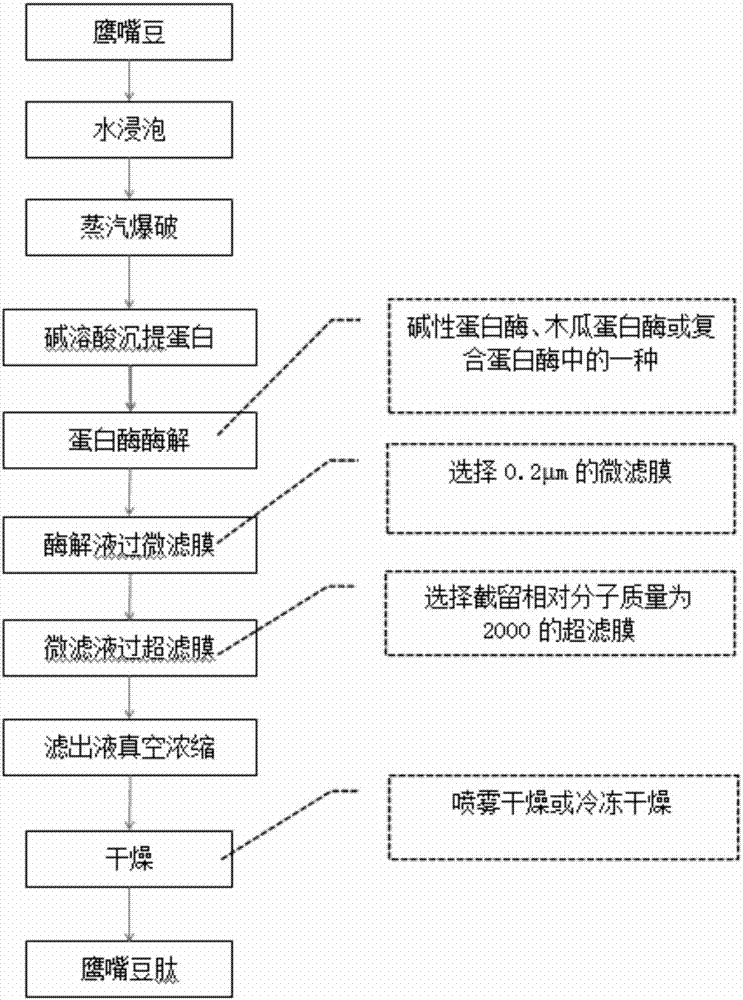

[0023] Such as figure 1 As shown, the chickpeas with skins were weighed according to the mass ratio of chickpeas and water of 1:2, mixed with water, soaked at room temperature for 8 hours, and then pretreated directly with steam explosion equipment. The steam pressure was 0.5MPa, and the pressure maintenance time was After 10 minutes, okara was obtained. Mix bean dregs and water at a mass ratio of 1:5, adjust the pH to 10 with sodium hydroxide, stir and extract at room temperature for 2 hours, and centrifuge after the extraction to obtain a filtrate. The pH of the filtrate was adjusted to 3.5 with hydrochloric acid, left to settle at room temperature for 2 h, and the supernatant was discarded by centrifugation to obtain a protein precipitate.

[0024] The obtained protein precipitate was mixed with water according to the mass ratio of 1:10, then added to the enzymolysis tank, the enzymolysis temperature was set at 50°C, the pH was adjusted to 8 with sodium hydroxide, and a co...

Embodiment 2

[0027] Weigh the chickpeas with skin and water according to the mass ratio of 1:2 (garbanzo: water), mix them at room temperature for 8 hours, and then directly pretreat them with steam explosion equipment. The steam pressure is 1.0 MPa, and the pressure maintenance time is 5 minutes. Get okara. Mix bean dregs and water at a mass ratio of 1:5, adjust the pH to 9 with sodium hydroxide, stir and extract at room temperature for 2 hours, and centrifuge after the extraction to obtain a filtrate. The pH of the filtrate was adjusted to 3 with hydrochloric acid, left to settle at room temperature for 2 h, and the supernatant was discarded by centrifugation to obtain a protein precipitate.

[0028] The obtained protein precipitate is mixed with water according to the mass ratio of 1:8 and then added to the enzymolysis tank, the enzymolysis temperature is set at 60°C, the pH is adjusted to 7 with sodium hydroxide, and papain (enzyme activity ≥ 8×10 6 U / g), 200r / min enzymatic hydrolysi...

Embodiment 3

[0031] Weigh the skinned chickpeas and mix them with water at a mass ratio of 1:2, soak them at room temperature for 8 hours, and then directly pretreat them with steam explosion equipment. The steam pressure is 0.8 MPa, and the pressure maintenance time is 8 minutes to obtain okara. Mix bean dregs and water at a mass ratio of 1:5, adjust the pH to 11 with sodium hydroxide, stir and extract at room temperature for 2 hours, and centrifuge after the extraction to obtain a filtrate. The pH of the filtrate was adjusted to 4 with hydrochloric acid, left to settle at room temperature for 2 h, and the supernatant was discarded by centrifugation to obtain a protein precipitate.

[0032] The obtained protein precipitate was mixed with water according to the mass ratio of 1:9, then added to the enzymolysis tank, the enzymolysis temperature was set at 55°C, the pH was adjusted to 8 with sodium hydroxide, and alkaline protease (enzyme activity) of 0.2% of the protein precipitate mass was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com