Graphene/MoS2 graphene and amorphous carbon composite material and preparation method thereof

A technology of amorphous carbon and composite materials, applied in electrical components, battery electrodes, circuits, etc., to achieve super-mechanical properties, high mechanical properties, and enhanced electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

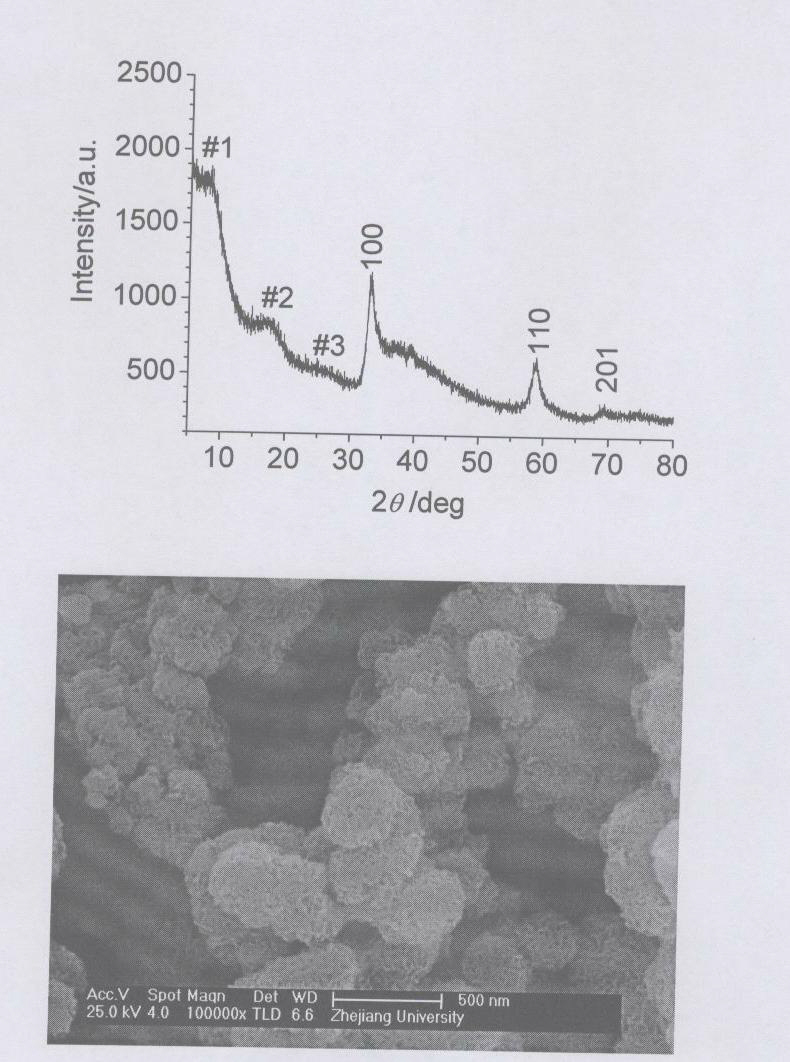

Embodiment 1

[0017] Graphene nanosheets and MoS 2 Preparation method of composite nanomaterial of graphene-like nanosheet and amorphous carbon:

[0018] 1) Preparation of graphite oxide nanosheets: Disperse 1.25mmol (0.015g) of graphite powder into 20mL of concentrated sulfuric acid in an ice bath at 0°C, and add KMnO 4 , the added KMnO 4 The mass of graphite is 3 times that of graphite, stir for 30 minutes, the temperature rises to about 30°C, add 45ml of deionized water, stir for 20 minutes, add 10ml of 30% H 2 o 2, stirred for 5 minutes, centrifuged, and repeatedly washed with a mass concentration of 5% HCl solution, deionized water and acetone to obtain graphite oxide nanosheets;

[0019] 2) Dissolve 1.25mmol (0.303g) of sodium molybdate in 63ml of deionized water to form a 0.02M solution, add 6.25mmol of thiourea and 1g (5.56mmol) of glucose, stir evenly, and the mixture of thiourea and sodium molybdate The ratio of mass is 5.0: 1, and the ratio of the mass of glucose to sodium mo...

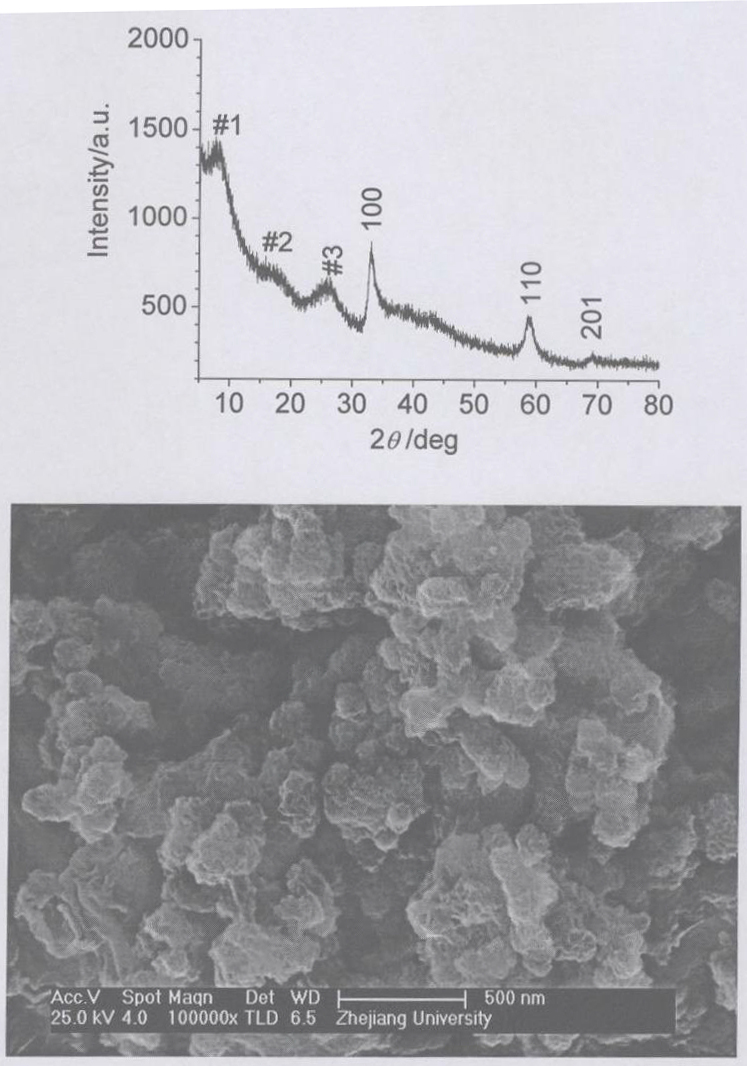

Embodiment 2

[0021] Graphene nanosheets and MoS 2 Preparation method of composite nanomaterial of graphene-like nanosheet and amorphous carbon:

[0022] 1) Preparation of graphite oxide nanosheets: Disperse 2.5mmol (0.03g) of graphite powder into 24mL of concentrated sulfuric acid in an ice bath at 0°C, and add KMnO 4 , the added KMnO 4 The mass of graphite is 3.5 times that of graphite, stir for 40 minutes, the temperature rises to about 34 ° C, add 45 ml of deionized water, stir for 25 minutes, add 12 ml of 30% H 2 o 2 , stirred for 7 minutes, centrifuged, and repeatedly washed with a mass concentration of 5% HCl solution, deionized water and acetone to obtain graphite oxide nanosheets;

[0023] 2) Dissolve 1.25mmol (0.303g) of sodium molybdate in 63ml of deionized water to form a 0.02M solution, add 7.5mmol of thioacetamide and 1g (5.56mmol) of glucose and stir well, in which thioacetamide and molybdenum The ratio of the amount of substance of sodium molybdate is 6: 1, and the ratio...

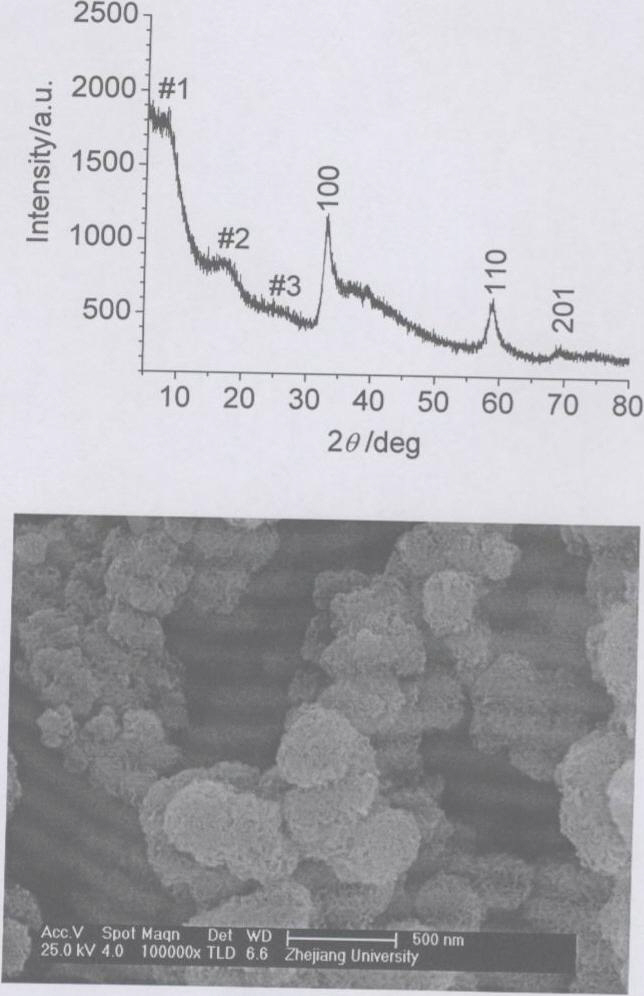

Embodiment 3

[0025] Graphene nanosheets and MoS 2 Preparation method of composite nanomaterial of graphene-like nanosheet and amorphous carbon:

[0026] 1) Preparation of graphite oxide nanosheets: Disperse 5.0 mmol (0.06 g) of graphite powder into 25 mL of concentrated sulfuric acid in an ice bath at 0 °C, and add KMnO 4 , the added KMnO 4 The mass of graphite is 4 times that of graphite, stir for 50 minutes, the temperature rises to about 35°C, add 50ml of deionized water, stir for 30 minutes, add 15ml of H2O with a mass concentration of 30% 2 o 2 , stirred for 10 minutes, centrifuged, and repeatedly washed with a mass concentration of 5% HCl solution, deionized water and acetone to obtain graphite oxide nanosheets;

[0027] 2) Dissolve 1.25mmol (0.303g) sodium molybdate in 63ml of deionized water to form a 0.02M solution, add 10mmol of thioacetamide and 1g (5.56mmol) of glucose and stir well, thioacetamide and molybdenum The ratio of the mass of sodium molybdate is 8: 1, the ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com