Preparation method of nano-structure oil-water separation net membrane with self-cleaning and underwater super-oleophobic characteristics

An oil-water separation membrane, underwater superoleophobic technology, applied in separation methods, chemical instruments and methods, immiscible liquid separation, etc. Flux decline and other problems, to achieve strong mechanical properties, easy to use, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

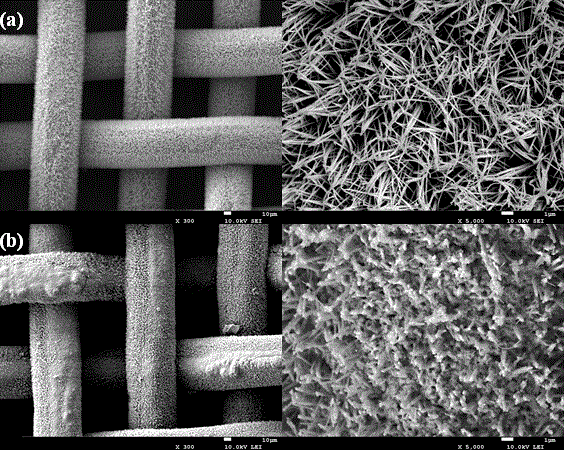

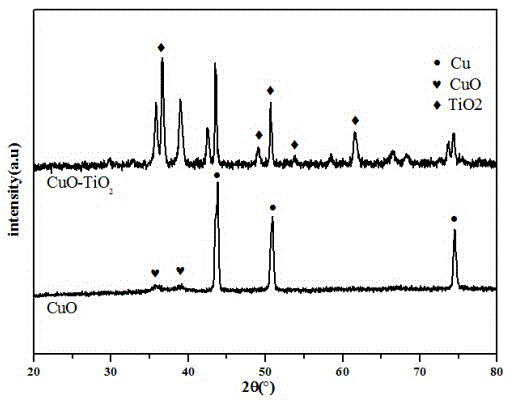

[0027] Embodiment 1: the preparation of oil-water separation copper mesh

[0028]a) pre-treat the cut 8×6 cm copper grid, first soak in acetone, absolute ethanol and deionized water for 15 minutes and perform ultrasonic cleaning respectively to remove oil stains on the surface of the copper grid; then soak in 1mol / In hydrochloric acid of L for 30 minutes, remove the oxide layer on the copper mesh surface;

[0029] b) The pretreated copper mesh is used as the anode, and the titanium sheet with the same area is used as the cathode, which is fixed in the electrolytic cell and connected to a constant voltage and constant current DC power supply, and the electrolyte is 1mol / L of potassium hydroxide and 0.5mol / L of ammonium chloride For the mixed solution, ensure that the areas of the cathode and anode in the immersed solution are the same, the distance between the electrodes is 2 cm, and the height of the copper mesh and the platinum sheet not immersed in the solution is 2 cm. Ca...

Embodiment 2

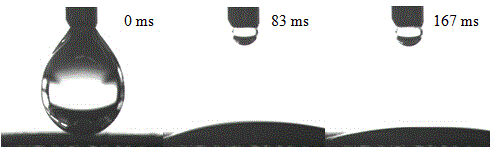

[0034] Embodiment 2: the oil-water mixture separation experiment of oil-water separation copper mesh

[0035] Figure 5 The experimental device for intermittent oil-water separation is shown. The oil-water separation copper mesh film covered by the prepared copper oxide / ten-layer titanium dioxide composite film layer is fixed between the fixtures. The upper end is the feeding glass tube, and the lower part is the discharging glass tube. Mix 25ml of kerosene and 25ml of deionized water (volume ratio 1:1) in 100ml of biscuits, add a small amount of Sudan III staining agent for staining, and stir for 30 minutes with magnetic force (the particle size of oil droplets is between 20 and 30 microns between), to obtain an oil-water mixture. First pre-wet the surface of the copper mesh with deionized water, then pour the mixture of kerosene and water on the above-mentioned oil-water separation copper mesh through the upper feed glass tube, the water flows out through the mesh through t...

Embodiment 3

[0037] Example 3: Self-cleaning regeneration and reuse experiment of oil-water separation copper mesh

[0038] Take the same device and process as in Example 2, pour the mixture of kerosene and water repeatedly on the oil-water separation copper mesh, each time the volume of the oil-water mixture is 50 milliliters, measure the COD in the water phase to judge the copper mesh degree of pollution. Such as Figure 6 As shown, for the oil-water separation membrane newly prepared in the above steps, the water phase COD of the first oil-water separation is lower than 50ppm, the water phase COD is lower than 60ppm after the oil-water separation is repeated for the second time, and the water phase of the oil-water mixture is reused for the third time COD rapidly increased to 175ppm, indicating that the oil-water separation copper mesh may be polluted by a small amount of oil droplets.

[0039] Separate the oil-water copper mesh from Figure 5 The shown experimental device was remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com