Flexible high-strength MXene-based electromagnetic shielding composite film and preparation method thereof

An electromagnetic shielding and composite film technology, which is applied in the directions of synthetic cellulose/non-cellulose material pulp/paper, textiles and papermaking, paper making machines, etc. Weakness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

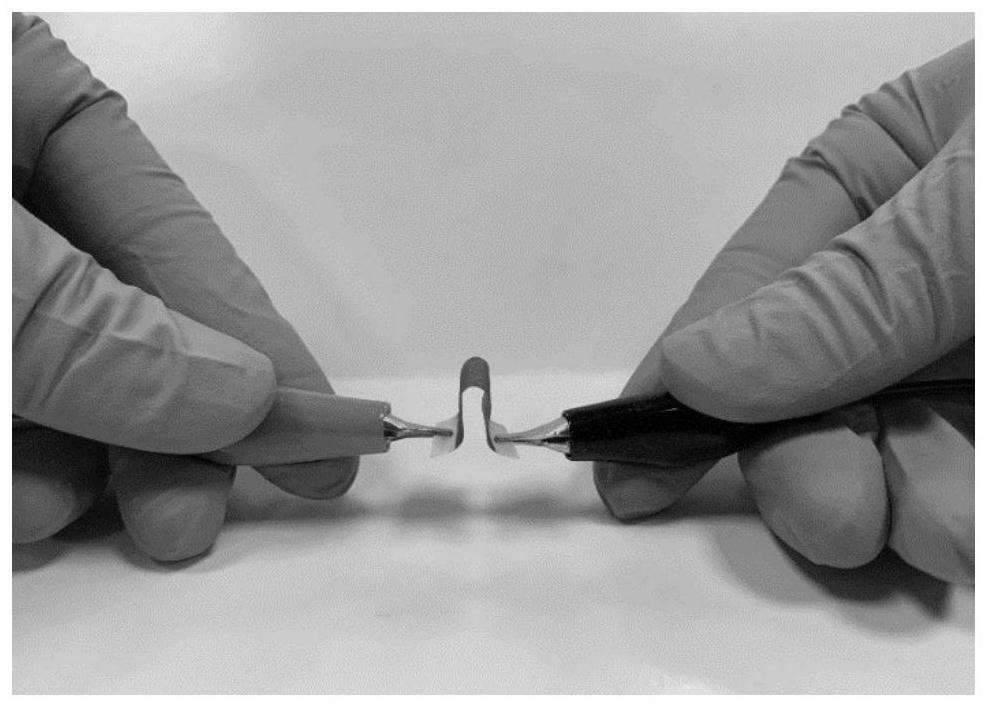

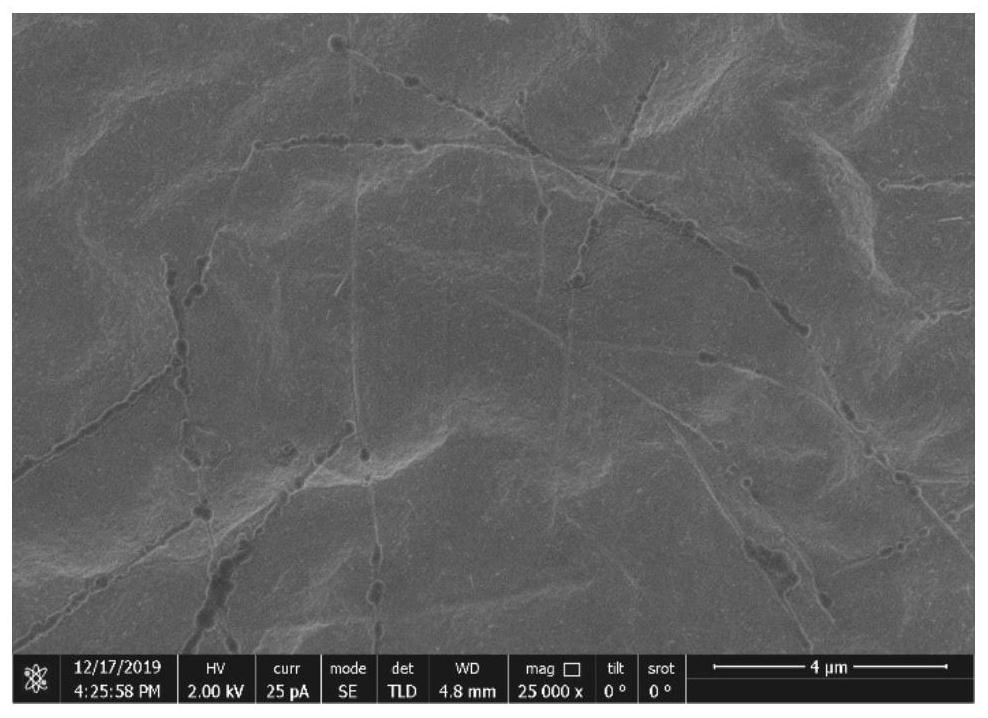

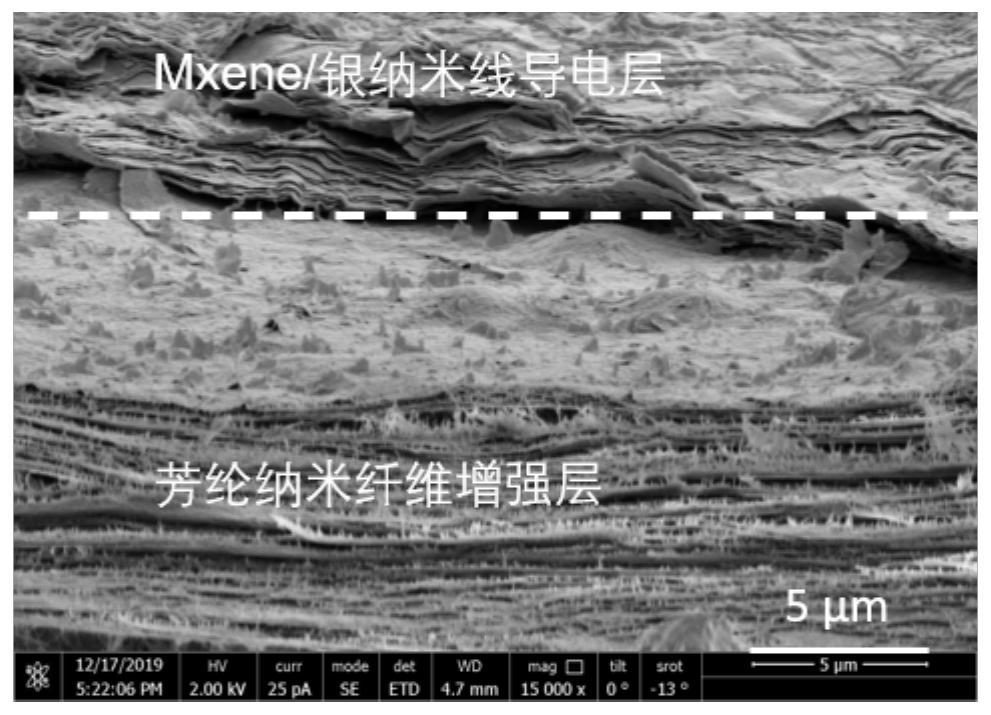

Image

Examples

preparation example Construction

[0034] The preparation method of the flexible high-strength MXene-based electromagnetic shielding composite film of the present invention specifically comprises the following steps:

[0035] Step 1, immerse the para-aramid fiber into the mixed solution of potassium hydroxide and dimethyl sulfoxide, and stir at room temperature to obtain a deep red aramid nanofiber dispersion; Lun nanofibers have a diameter of 5-20nm and a length of 5-20μm;

[0036] In step 1, the aramid nanofiber is based on a kind of para-aramid yarn fiber, para-aramid chopped fiber, and para-aramid fabric fiber as a raw material, and mixed solution of potassium hydroxide and dimethyl sulfoxide It is prepared in the system, and the ratio of para-aramid fiber, potassium hydroxide and dimethyl sulfoxide is 0.5-1.5g:1-2g:100-1000mL;

[0037] Wherein step 1, the aramid nanofiber dispersion liquid can be uniformly dispersed in deionized water, the aramid nanofiber diameter is 5-20nm, the length is 5-20μm, and the...

Embodiment 1

[0053] A flexible and high-strength MXene-based electromagnetic shielding composite film including Ti 3 C 2 T x MXene, silver nanowires and aramid nanofibers; Ti in flexible high-strength MXene-based electromagnetic shielding composite films 3 C 2 T x The mass fraction of MXene / silver nanowires is 10%; Ti in the flexible and high-strength MXene-based electromagnetic shielding composite film 3 C 2 T x The mass ratio of MXene to silver nanowires is 10:0.5; aramid nanofibers are prepared from para-aramid yarn fibers in a mixed solution of potassium hydroxide and dimethyl sulfoxide, and aramid nanofibers Fiber diameter is 5-20nm, length is 5-20μm; Ti 3 C2 T x The size of the MXene sheet is 100-300nm; the diameter of the silver nanowire is 20-50nm, and the aspect ratio is 500-1000; the hot-pressing pressure of the flexible and high-strength MXene-based electromagnetic shielding composite film is 0.5MPa.

[0054] The preparation method of flexible high-strength MXene-ba...

Embodiment 2

[0056] Flexible and high-strength MXene-based electromagnetic shielding composite films, including Ti 3 C 2 T x MXene, silver nanowires and aramid nanofibers; Ti in flexible high-strength MXene-based electromagnetic shielding composite films 3 C 2 T x The mass fraction of MXene / silver nanowires is 20%; Ti in the flexible and high-strength MXene-based electromagnetic shielding composite film 3 C 2 T x The mass ratio of MXene to silver nanowires is 10:1; aramid nanofibers are prepared from para-aramid chopped fibers in a mixed solution of potassium hydroxide and dimethyl sulfoxide, and aramid nanofibers Fiber diameter is 5-20nm, length is 5-20μm; Ti 3 C 2 T x The size of the MXene sheet is 100-300nm; the diameter of the silver nanowire is 20-50nm, and the aspect ratio is 500-1000; the hot-pressing pressure of the flexible high-strength MXene-based electromagnetic shielding composite film is 1MPa.

[0057] A method for preparing a flexible high-strength MXene-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com