Continuous vacuum welding furnace and welding method for same

A vacuum welding furnace and high vacuum technology, applied in welding equipment, electric heating devices, auxiliary devices, etc., can solve the problems of welding equipment temperature stress fatigue damage, reduce welding efficiency, energy loss, etc., to reduce energy loss and save welding time , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

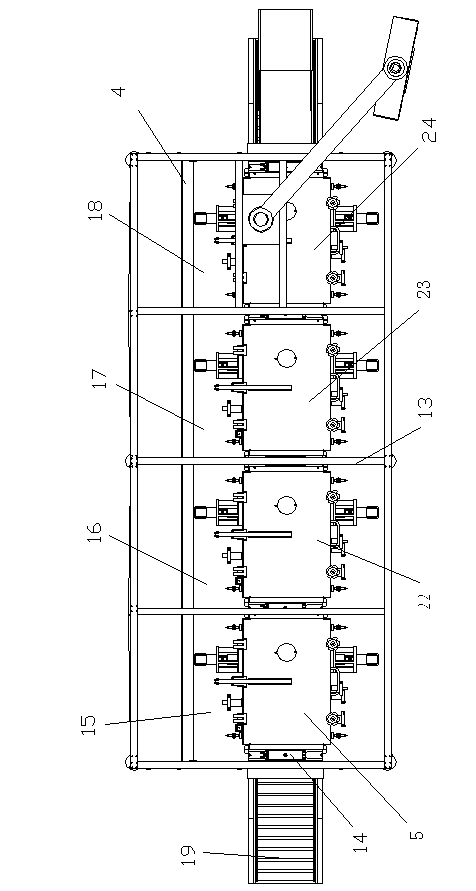

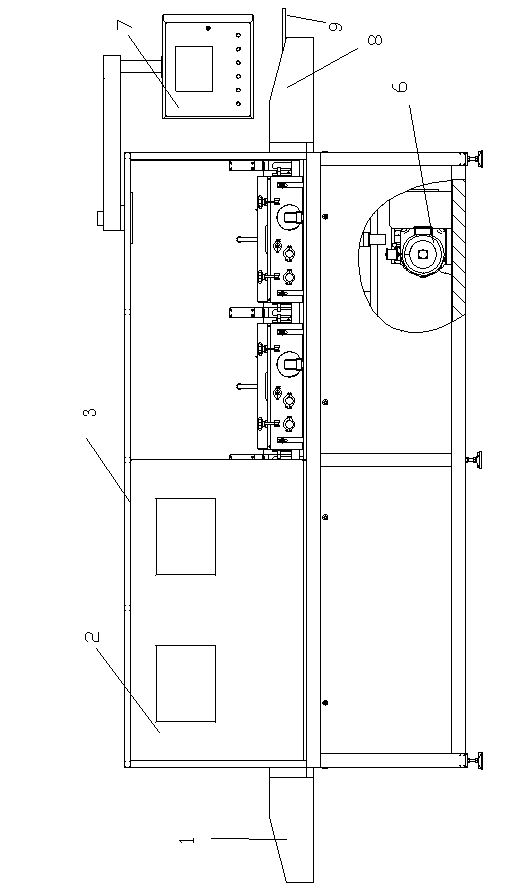

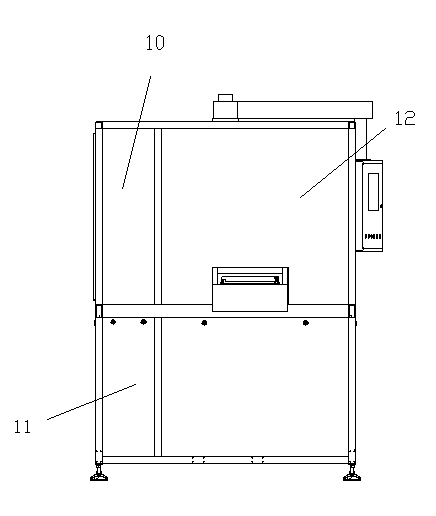

[0034] Below, the embodiments of the present invention will be further described in conjunction with the accompanying drawings.

[0035] figure 1 , figure 2 , image 3 Show the structural schematic diagram of the main functional components of the continuous vacuum welding furnace. The present invention mainly consists of a feeding part 1, a frame 3, a heat insulating layer 4, a first vacuum chamber part 5, a second vacuum chamber part 22, a third vacuum chamber part 23, a fourth vacuum chamber part 24, Vacuum pump 6, programmable logic controller 7, discharge unit 8, electrical cabinet 10, pneumatic cabinet 11, working room 12 and so on. The working chamber 12 is a cuboid structure, and the first vacuum chamber part 5 , the second vacuum chamber part 22 , the third vacuum chamber part 23 and the fourth vacuum chamber part 24 are arranged in the working chamber sequentially from left to right. An electrical control device is provided in the electrical cabinet 10 , and a pn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com