Automatic welding equipment

An automatic welding and equipment technology, applied in welding equipment, metal processing equipment, tin feeding devices, etc., can solve the problems of difficult to meet the requirements of welding temperature control, complicated operation and process, large equipment space, etc., to achieve compact structure, The effect of high personnel and equipment safety and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

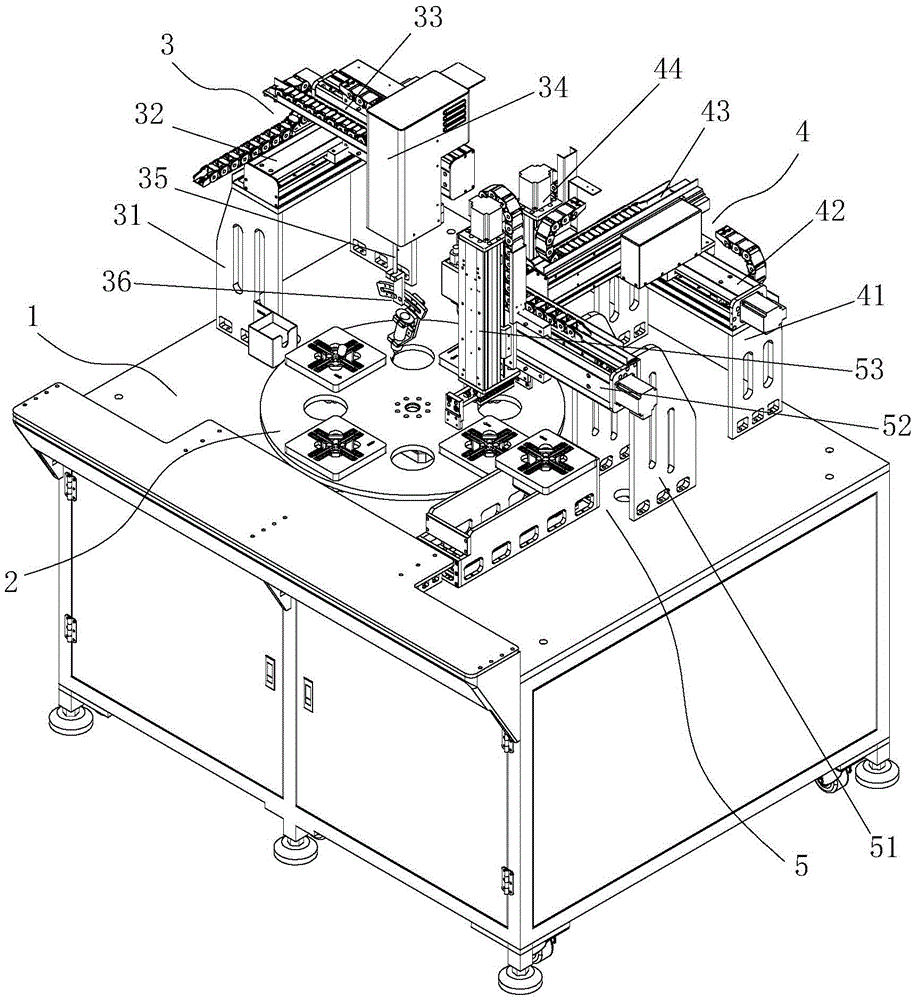

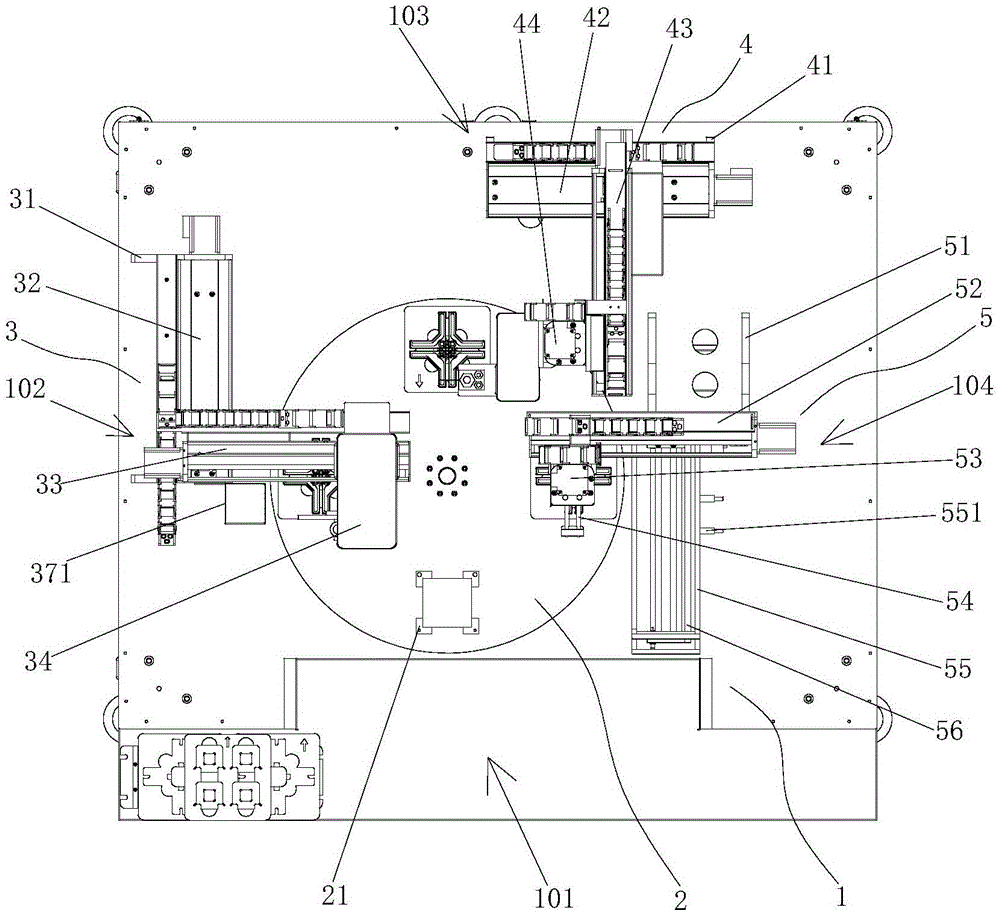

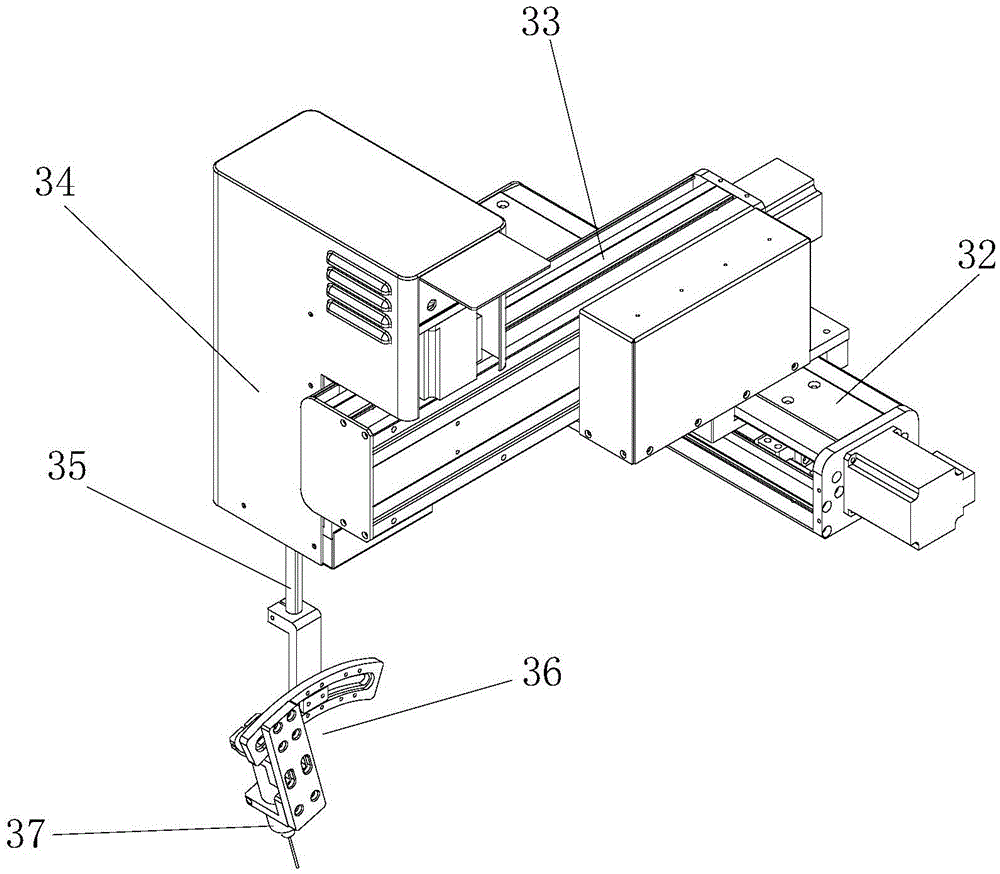

[0029] Such as figure 1 , figure 2 As shown, what the present invention describes is an automatic soldering equipment, which has a main frame 1, and the automatic soldering equipment includes an index plate 2, a solder paste dispensing assembly 3, and a high-frequency soldering assembly 4 arranged on the main table 1. And the blanking assembly 5, wherein, four workpiece positioning parts 21 are evenly arranged on the said indexing plate 2; four stations are formed on the periphery of the main frame 1 and the indexing plate 2, wherein the first station 101 is Manual loading station, the second station 102 is equipped with solder paste assembly 3, the third station 103 is installed with high-frequency solder assembly 4, and the fourth station 104 is installed with blanking assembly 5;

[0030] In general, manual loading is to manually place the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com