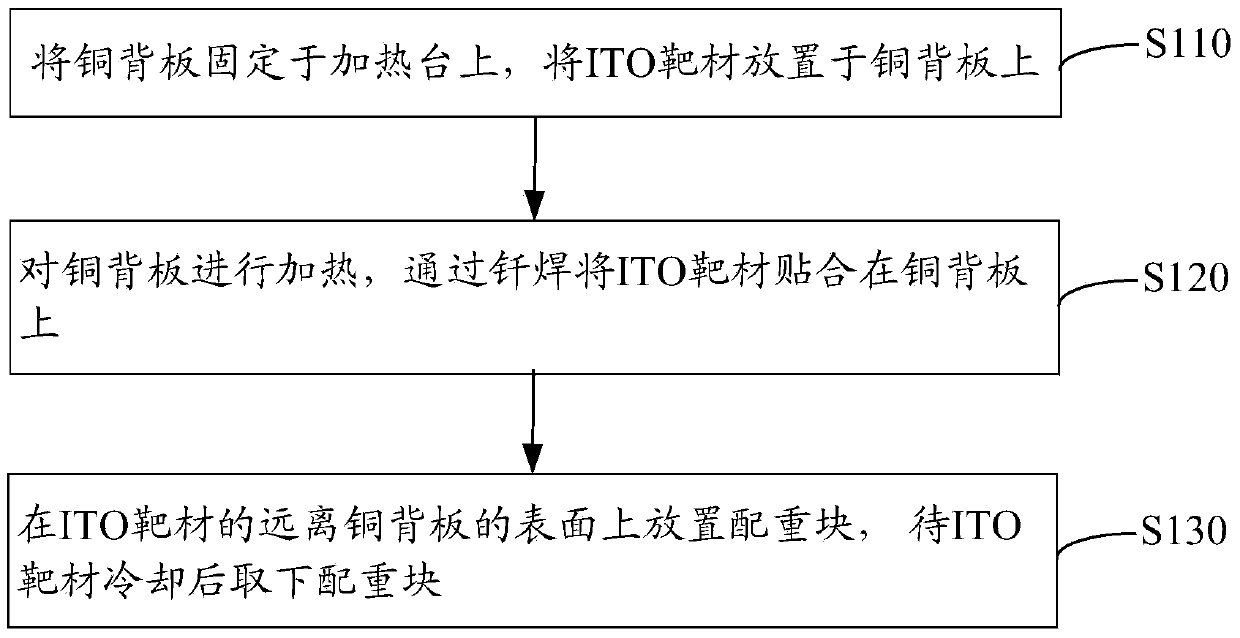

Method for binding ITO target to copper back plate

A copper backplane and target technology, which is applied to electric heating devices, auxiliary devices, manufacturing tools, etc., can solve the problems affecting the stability of the coating process, the quality of the film formation, and the poor binding quality of the ITO target and the copper backplane. , to solve the uneven fluidity of indium, improve the binding quality, and avoid the effect of air holes on the bonding surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Bonding of ITO target and copper backplane

[0051] 1. Drill and tap on the heating table so that two rows of screw holes are formed on the heating table, each row has three screw holes distributed at equal intervals, and the two rows of screw holes are opposite to each other. Drill holes on two bar-shaped copper briquetting blocks, drill 3 holes at equal intervals along the length of each bar-shaped copper briquetting block, and place the copper backplane on the heating table, respectively. Use the undrilled ends of the above two bar-shaped copper briquetting blocks to press the two ends of the copper back plate, use screws to pass through the holes on the two bar-shaped copper briquetting blocks and the screw holes on the heating table, and lock the copper The backplane is fixed on the heating table. Then, place an ITO target with a length×width×thickness of 200mm×120mm×6mm on the copper backplane;

[0052] 2. Heat the copper back plate from room temperature to 50°C...

Embodiment 2

[0055] Bonding of ITO target and copper backplane

[0056] 1. Drill and tap on the heating table so that two rows of screw holes are formed on the heating table, each row has three screw holes distributed at equal intervals, and the two rows of screw holes are opposite to each other. Drill holes on two strip-shaped aluminum compacts, drill three holes at equal intervals along the length of each strip-shaped copper compact, and place the copper backplane on the heating table. Use the undrilled ends of the above-mentioned two bar-shaped aluminum briquetting blocks to press the two ends of the copper back plate, use screws to pass through the holes on the two bar-shaped aluminum briquetting blocks and the screw holes on the heating table, and lock the copper The backplane is fixed on the heating table. Then, place an ITO target with a length×width×thickness of 200mm×120mm×6mm on the copper backplane;

[0057] 2. Heat the copper back plate from room temperature to 50°C at a heat...

Embodiment 3

[0060] Bonding of ITO target and copper backplane

[0061] 1. Drill and tap on the heating table so that two rows of screw holes are formed on the heating table, each row has three screw holes distributed at equal intervals, and the two rows of screw holes are opposite to each other. Drill holes in two bar-shaped brass briquettes, drill 3 holes at equal intervals along the length of each bar-shaped copper briquette on the edge of one end of the bar-shaped aluminum briquette, place the copper backplate on the heating table, Use the undrilled ends of the above two strip-shaped brass briquetting blocks to press the two ends of the copper back plate respectively, and use screws to pass through the holes on the two strip-shaped brass briquetting blocks and the screw holes on the heating table, and lock them tightly. Finally, fix the copper backplane on the heating table. Then, place an ITO target with a length×width×thickness of 200mm×120mm×6mm on the copper backplane;

[0062] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com