Heating and cooling device

A technology of cooling equipment and cooling section, applied in metal processing equipment, welding equipment, welding equipment and other directions, can solve the problems of lack of cooling device, poor efficiency, time-consuming and other problems, to shorten processing time, efficient heating and cooling, improve The effect of heating and cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

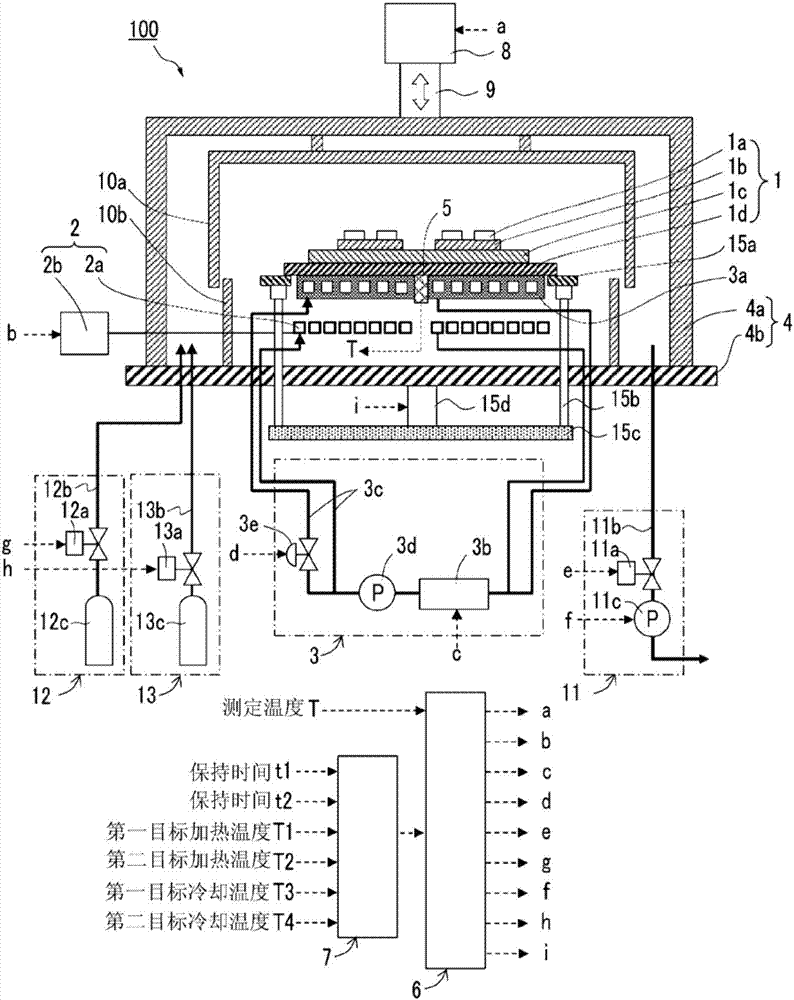

[0060] Below, refer to figure 1 One embodiment of the heating and cooling equipment according to the present invention will be described.

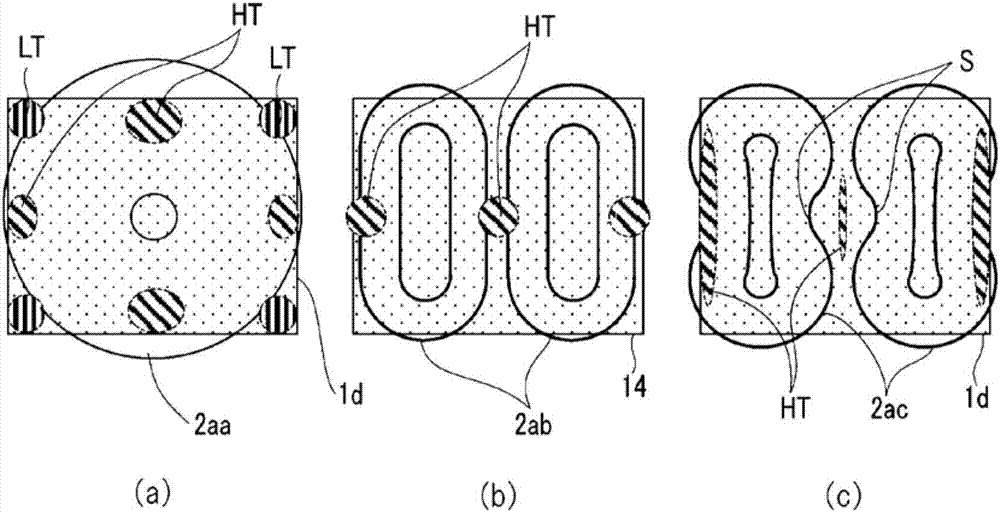

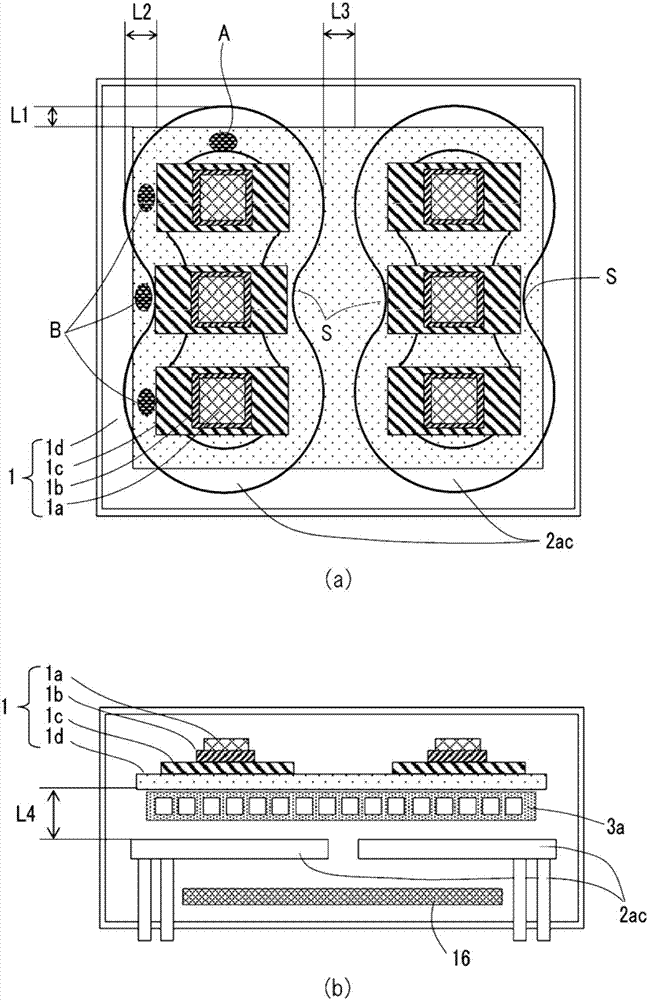

[0061] figure 1 A schematic structural diagram of the heating and cooling device 100 is shown in . The heating and cooling equipment 100 is equipped with: an airtight processing chamber 4, which has an opening and closing mechanism that can take out and put in the processed member 1; the cooling part 3a of the cooling device 3, which is arranged below the processed member 1; The induction heating coil 2a of device 2, it is arranged in the below of cooling part 3a; Mobile device 15, it is used to change the distance between processed member 1 and cooling part 3a; Temperature sensor 5, it is used to measure processed member 1 the temperature; the control device 6, which controls the induction heating device 2 and the cooling device 3 based on the measured temperature; and the input device 7, which is used to input a signal to the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com