Integrated heating-placement hot air head

A limelight and placement technology, applied in the field of printed circuit board welding machines, can solve problems such as uneven temperature, large heat loss, slow heating/cooling, etc., to ensure placement accuracy and reliability, service life and high temperature resistance , Rapid heating/cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

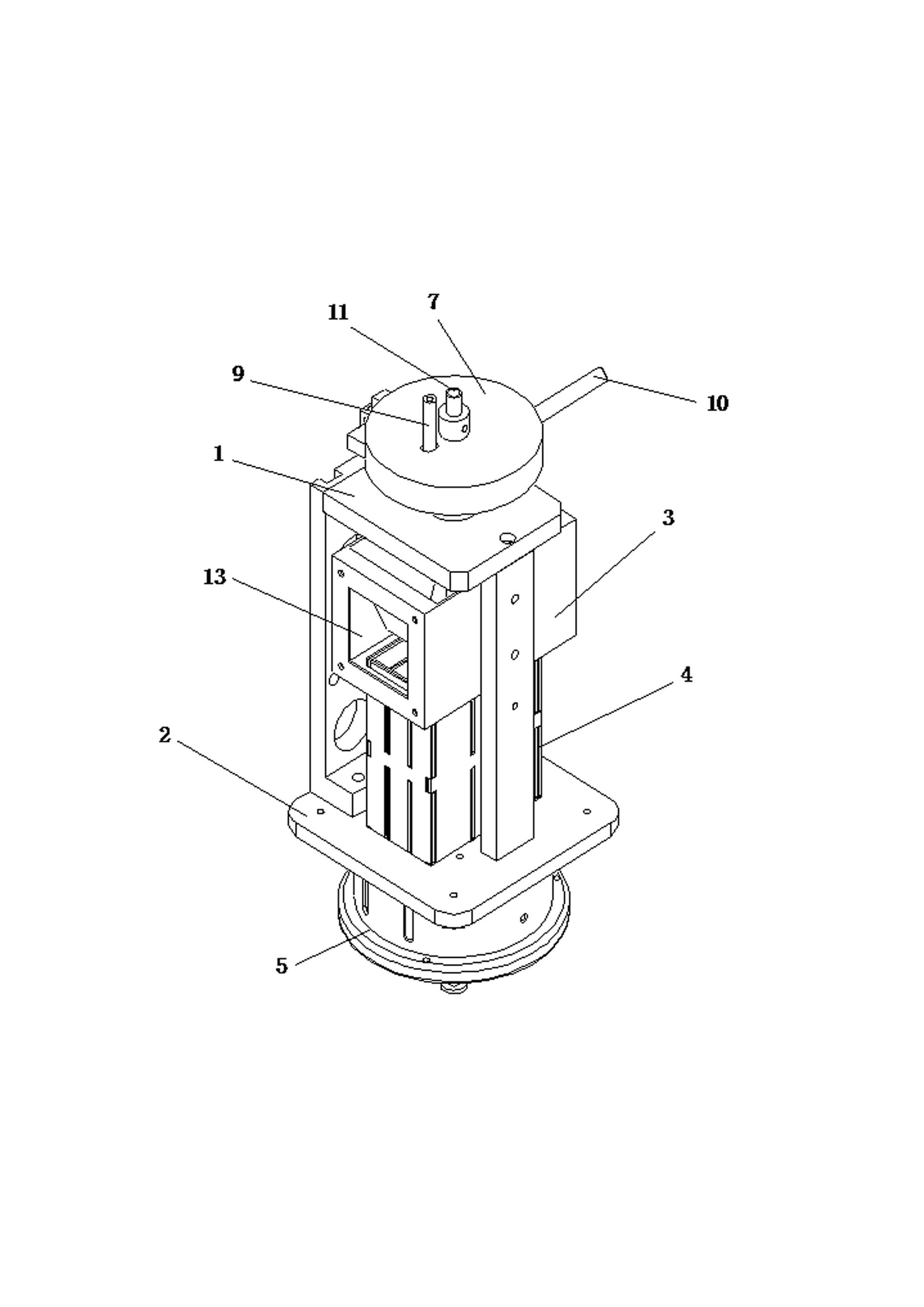

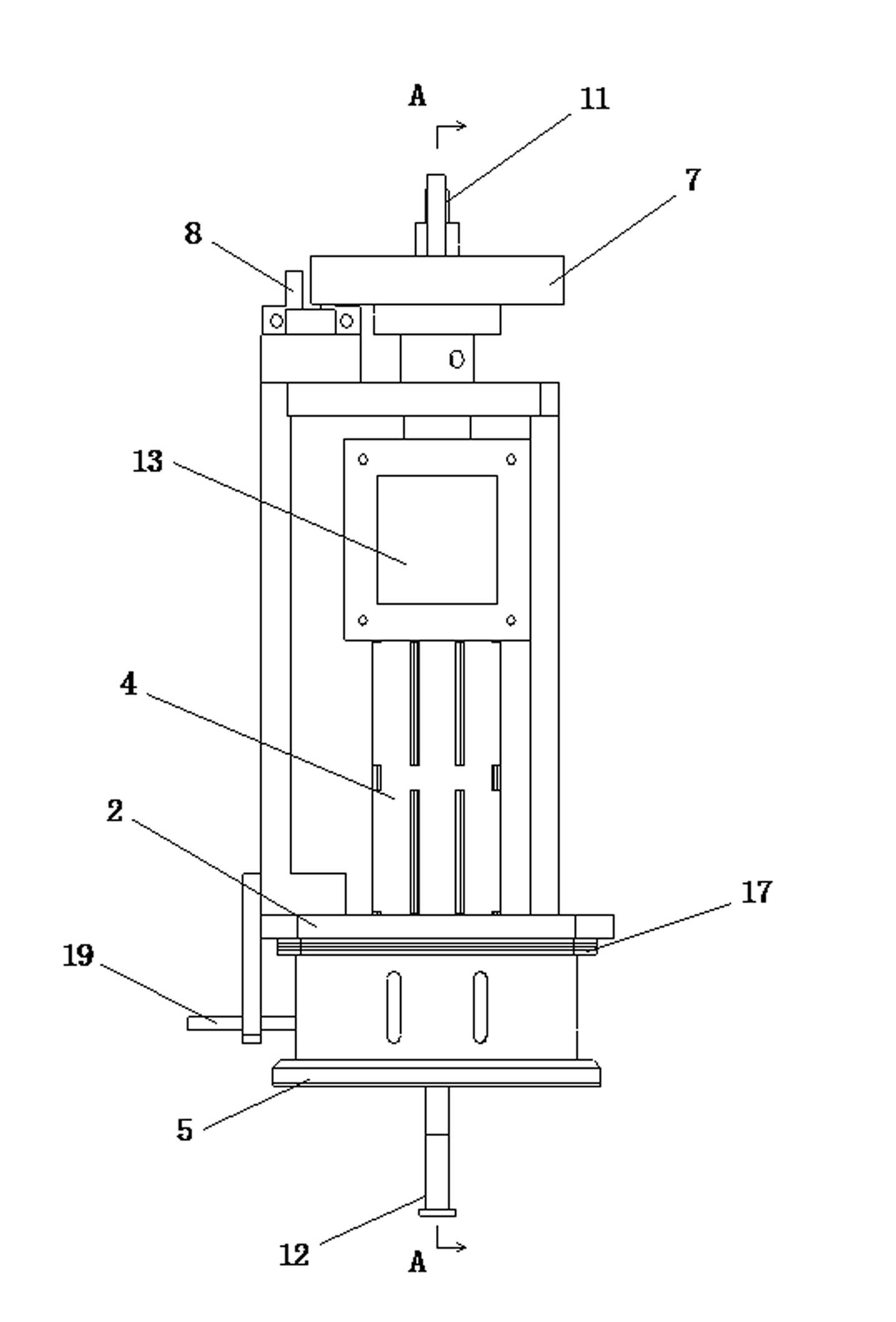

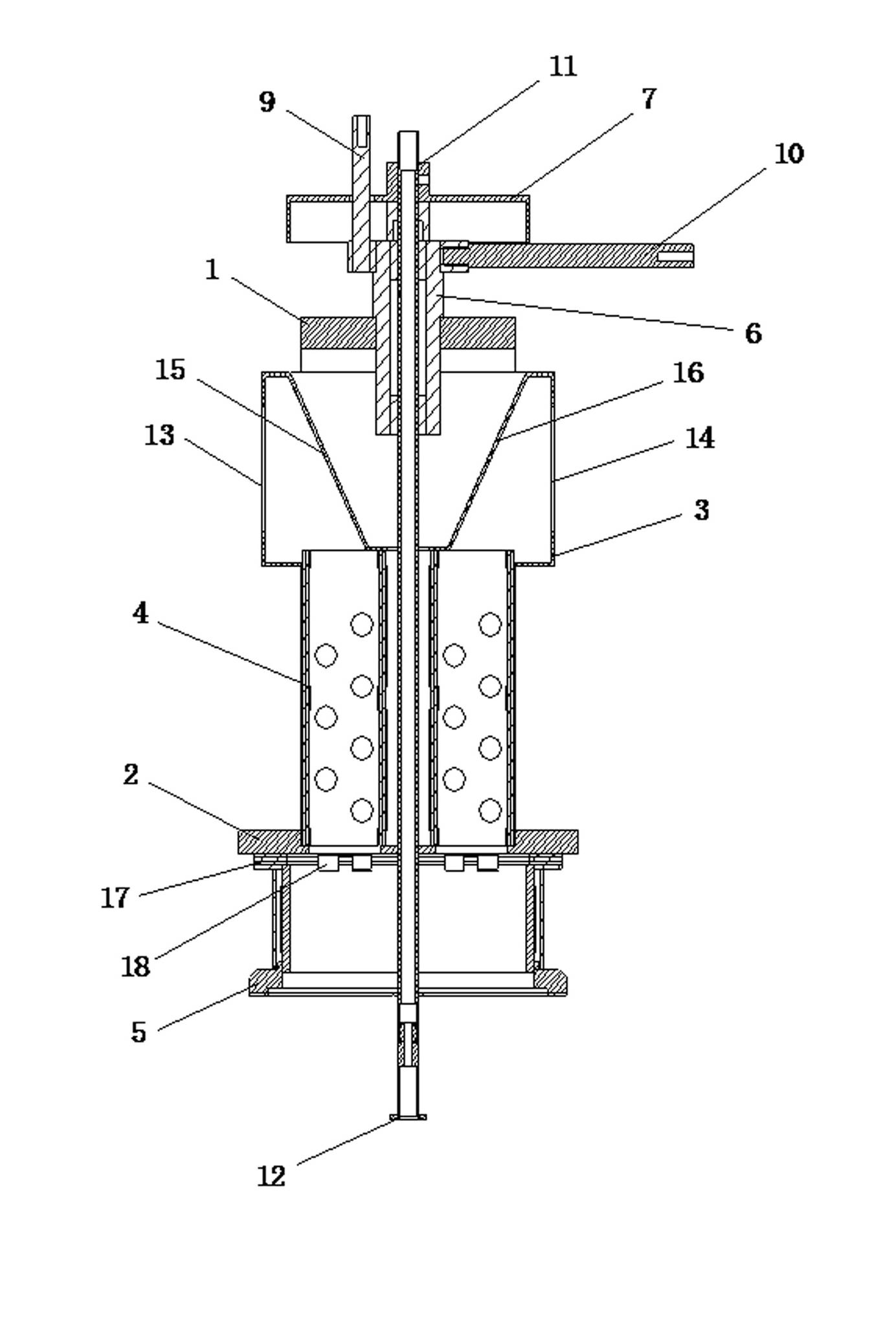

[0023] like Figure 1 to Figure 4 As shown, a heating and mounting integrated hot air head is characterized in that a heating core fixing seat 3 and a heating wire support 4 are installed between the upper and lower fixing plates 1 and 2, and the bottom of the lower fixing plate 2 is installed with The nozzle seat 5 and the upper fixing plate 1 are pierced with a hollow suction rod guide sleeve 6. The lower end of the suction rod guide sleeve 6 extends into the heating core fixing seat 3. The upper part of the suction rod guide sleeve 6 is equipped with a rotating induction coil 7. A sensor 8 is also arranged near the rotation induction coil 7, and a rotation transmission rod 9 is arranged between the rotation induction coil 7 and the suction rod guide sleeve 6, and the suction rod guide sleeve 6 is also connected with a rotation rod 10, and a suction rod 11 is induced by rotation. After the ring 7 enters, it passes through the suction rod guide sleeve 6 and extends out of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com