Fire-water correcting technology of aluminum-magnesium alloy ship

A technology of aluminum-magnesium alloy and aluminum alloy plate, which is applied in the field of deformation correction and can solve problems such as not advocating the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

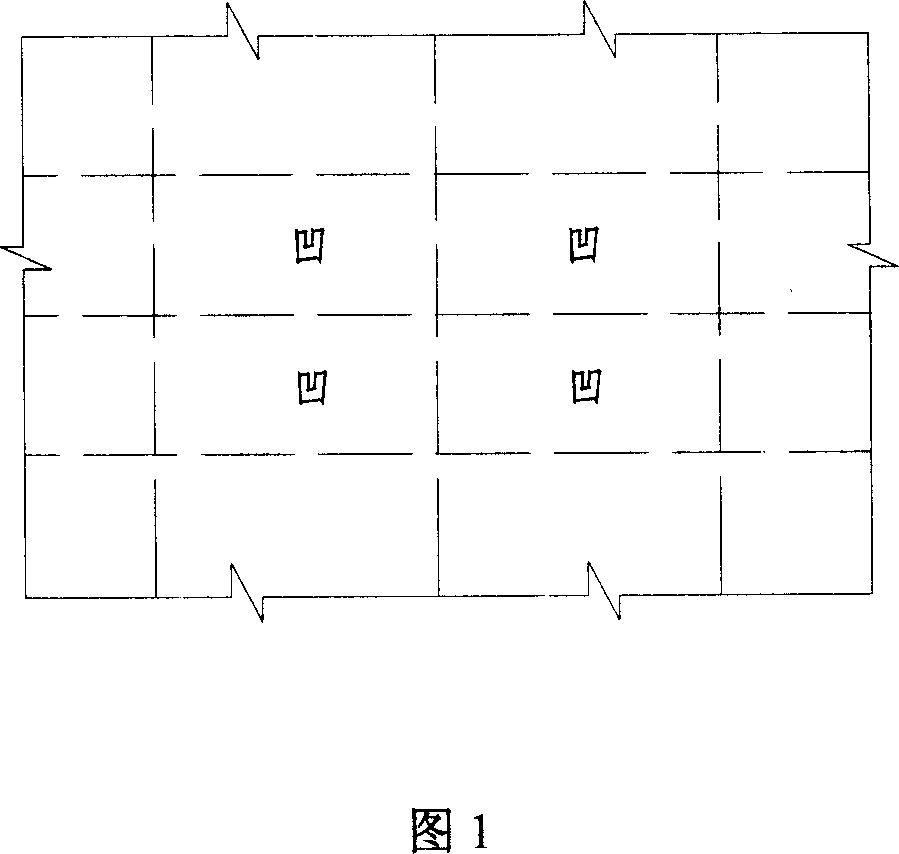

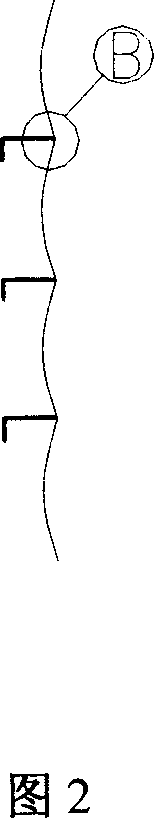

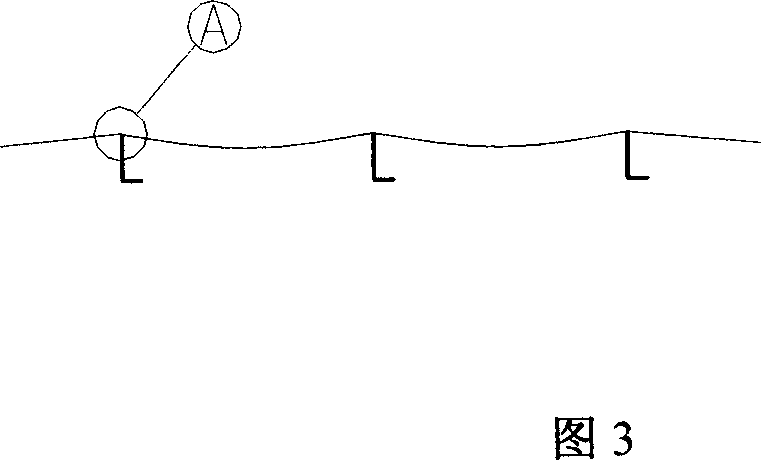

[0040] As shown in Figures 1 to 3, it is the phenomenon of "thin horse" bulging at the skeleton welding place that is often encountered in the hull plate or superstructure. The "thin horse" of the aluminum boat can even bulge up to 3mm, and its correction procedure is shown in Figure 8. The rectification method adopts linear heating, uses oxygen-acetylene mixed gas and medium nozzle as heating tool, and uses small tap water leather tube with control switch as cooling water tool. The process method is to use oxygen-acetylene flame to heat the aluminum plate, And then cooled with water, the distance between the flame and the aluminum plate is 30mm, the moving speed of the flame is 1500mm / min, the minimum distance between the flame and the cooling water is 40mm, and the heating temperature is controlled at 170-175°C. For the back of the B-shaped skeleton Backfire along the skeleton line, and backfire the back of the A-shaped skeleton along both sides of the skeleton line. After ...

Embodiment 2

[0042] As shown in Figures 4 to 5, the undulating wave deformation of the plate frame often occurs in the thin plate structure of the aluminum ship hull. The distance between the "peak" and "valley" of the wave can reach 15mm or even 25mm. This kind of deformation correction method is also mainly carried out by linear heating. Oxygen-acetylene mixed gas and a medium-sized nozzle are used as heating tools, and a small-sized tap water leather tube with a control switch is used as a cooling water tool. The process method is to use an oxy-acetylene flame to heat the aluminum plate, and then cool it with water. The flame The distance from the aluminum plate is 25mm, the moving speed of the flame is 1400mm / min, the minimum distance between the flame and the cooling water is 50mm, and the heating temperature is controlled at 165-170°C. In the first stage, at the skeletons on both sides of the protruding surface, the linear heating method is used for back burning, and gradually moves ...

Embodiment 3

[0044] Referring to Figures 6-7, it is the local bulging deformation of the hull. The thickness of the aluminum alloy plate is 6mm, and the dot-type heating method can be used for water and fire correction. Oxygen-acetylene mixed gas and medium-sized nozzles are used as heating tools, and Use a small tap water hose with a control switch as a cooling water tool. The process method is to use an oxy-acetylene flame to heat the aluminum plate and then cool it with water. The distance between the flame and the aluminum plate is 20mm, and the circular movement angular velocity of the flame is 120° / second, the minimum distance between the flame and the cooling water is 60mm. The heating temperature is controlled at 245-250°C. The diameter of the dot D=4t+10mm (t represents the plate thickness), but not more than 60mm, a=200~400mm, b=100~200mm. The heating starts from the place with small deformation, and moves to the place with large deformation in sequence. During the heating pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com