Heat treatment device and heat treatment method for rapid heating in pulsed magnet field

A technology of heat treatment device and pulsed magnetic field, which is applied in the field of material processing and special heat treatment, can solve the problems of low efficiency of magnetic field action, and achieve the effect of improving the efficiency of magnetic field action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

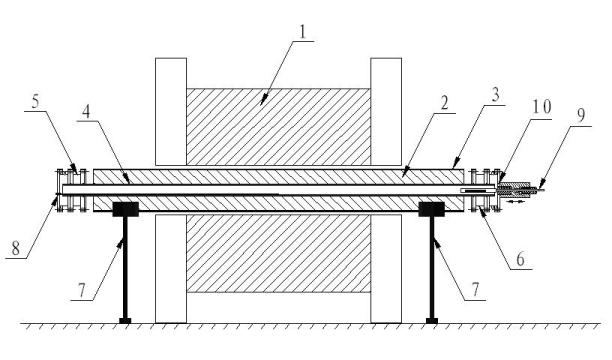

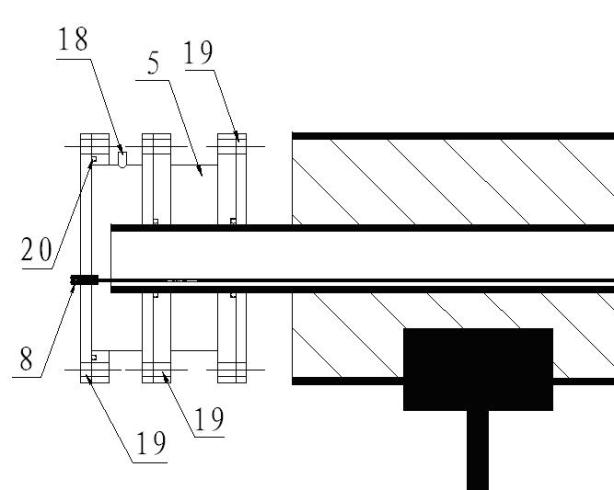

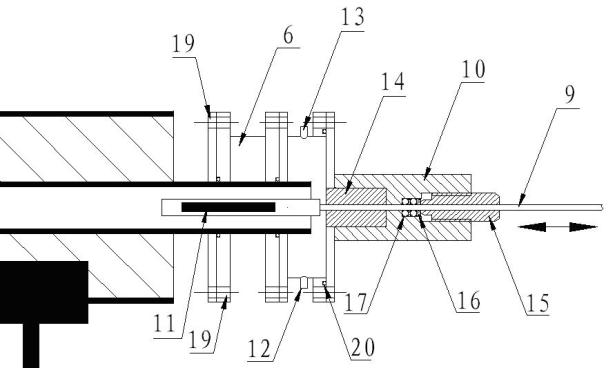

[0025] Now the specific embodiment of the present invention is further described as follows in conjunction with the accompanying drawings.

[0026] Such as figure 1 , figure 2 , image 3 As shown, a rapid heating heat treatment device under a pulsed magnetic field is composed of a magnetic field coil, a heating system, a sealing system, and a feeding device. The magnetic field coil 1 is connected to a high-voltage pulsed current source to generate a pulsed magnetic field in its cavity; the heating The system includes insulation material 2, quartz furnace shell 3, quartz furnace tube 4, armored thermocouple 8 and support 7, the outer side of the quartz furnace tube 4 is wound with a resistance wire in a double helix, the quartz furnace shell 3 and the The insulating material 2 is filled between the quartz furnace tubes 4, the armored thermocouple 8 is placed in the quartz furnace tube 4 to control the temperature of the quartz furnace tube 4, and the left and right ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com