A method and apparatus for processing metallic material within complex magnetic field

A metal material, high-temperature treatment technology, applied in the field of high-temperature treatment, to improve the solidification structure, refine the uniform distribution, and simplify the process route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

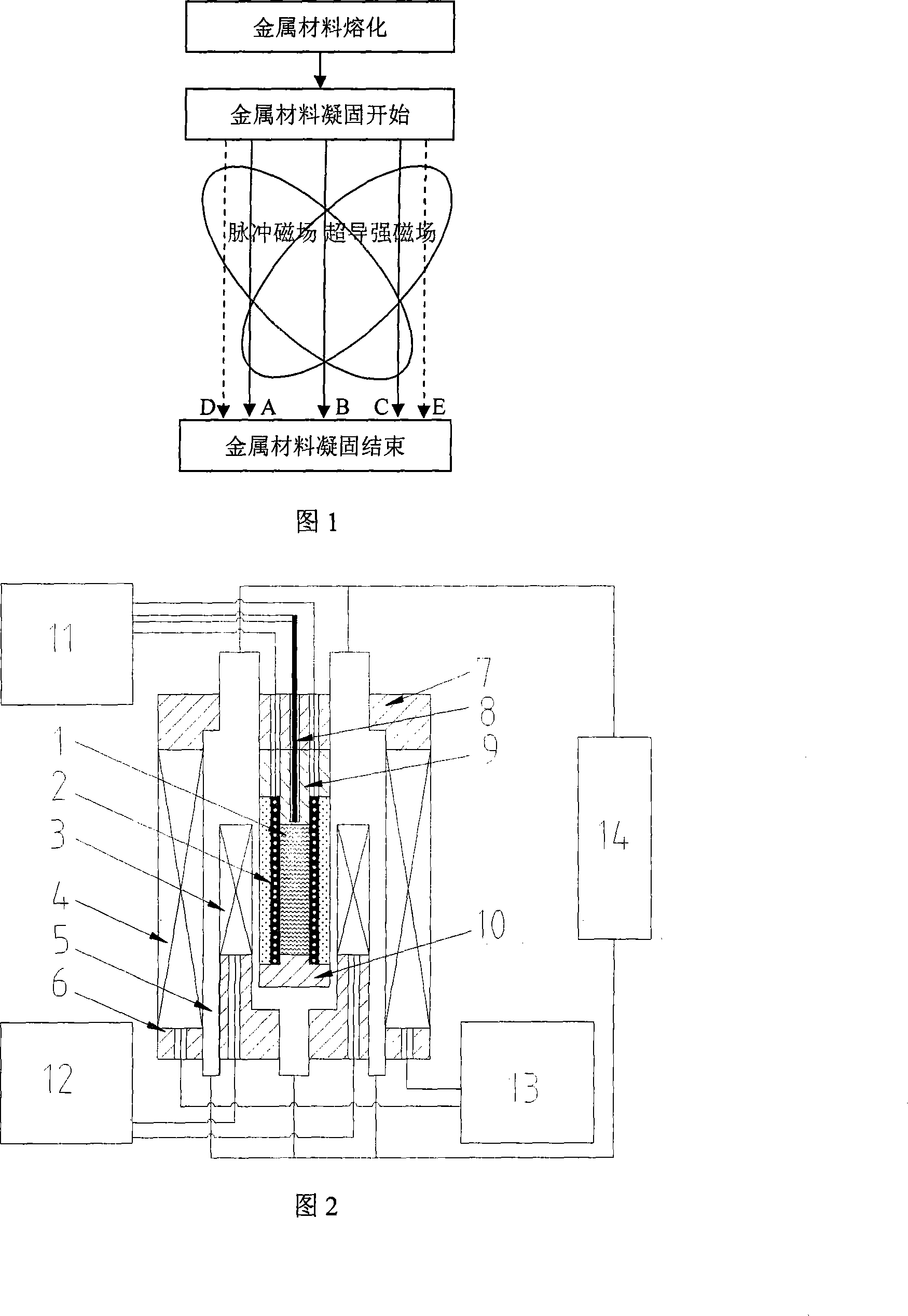

[0029] The device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] In the method of the invention, during the solidification process of the metal material, a coaxial and co-directional pulsed magnetic field and a superconducting strong magnetic field are applied to the metal material melt to control the grain size and crystal orientation.

[0031] As shown in Figure 1, A, B, C represent adopting the composite magnetic field application sequence and the mode that can be finished by the inventive method: A. first apply pulsed magnetic field, then apply superconducting strong magnetic field; B. apply pulsed magnetic field and superconducting strong magnetic field simultaneously Magnetic field; C. Apply a superconducting strong magnetic field first, and then apply a pulsed magnetic field. Dotted arrows D and E represent single magnetic field application methods used in other prior art: D. only pulsed magnetic field ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com