Device capable of continuously measuring temperature of metal melt in pulse magnetic oscillation processing technology

A pulsed magneto-oscillation, metal melt technology, applied in the configuration of indicating equipment/measuring equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to maintain consistency, difficult to obtain, violent flow, etc. effect, accurately measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

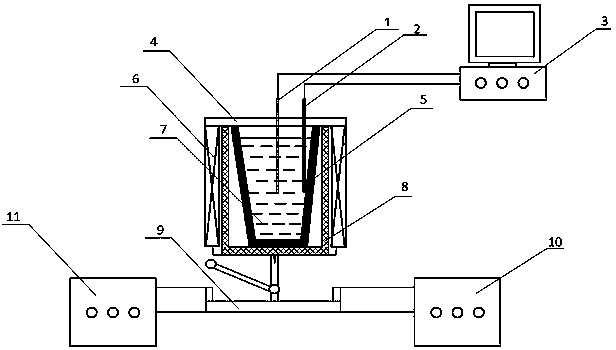

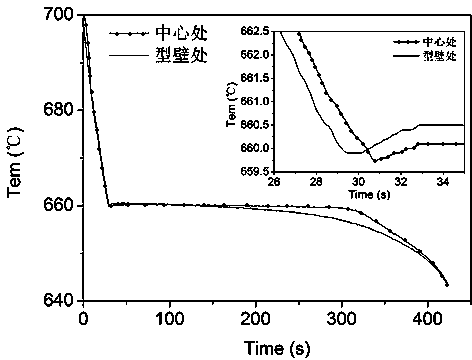

[0022] In this example, see figure 1 and figure 2 , a device for continuously measuring the temperature of molten metal in the pulsed magnetic oscillation treatment process, including a temperature test and analysis system, a melting and casting device and a pulse magnetic oscillation treatment device, the temperature test and analysis system consists of a temperature measuring thermocouple, a temperature acquisition and recording system 3 and a thermocouple fixing device, the signal output end of the temperature measuring thermocouple is connected to the signal receiving end of the temperature acquisition and recording system 3, and the temperature acquisition and recording system 3 monitors the temperature measurement value of the internal detection position of the metal melt 7 to be measured in real time, And output temperature measurement value information. The melting and casting device is composed of a casting device 5, an intermediate frequency induction power supply 1...

Embodiment 2

[0029] This embodiment is basically the same as Embodiment 1, especially in that:

[0030] By punching a plurality of holes on the top cover 4 of the casting device 5, the position, quantity and insertion depth of the thermocouples for temperature measurement can be adjusted respectively. In addition to using the first melt temperature measuring thermocouple 1 and the second melt temperature measuring thermocouple 2, a third melt temperature measuring thermocouple is added, and the distance between each thermocouple placed inside the metal melt is cast The distance from the bottom of the type device 5 is the same, so as to continuously measure the temperature at the position to be measured at the same depth in the molten metal 7, and draw the temperature change curve of the test point of the molten metal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com