Pulsed magnet field removing device for sawtooth adhered scraps

A technology of pulsed magnetic field and chip sticking, which is applied to the accessories of sawing machines, metal sawing equipment, maintenance and safety accessories, etc. It can solve the problems such as difficult removal of accumulated chips, improve cutting efficiency, reduce manual labor, and reduce roughness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, this patent is further described.

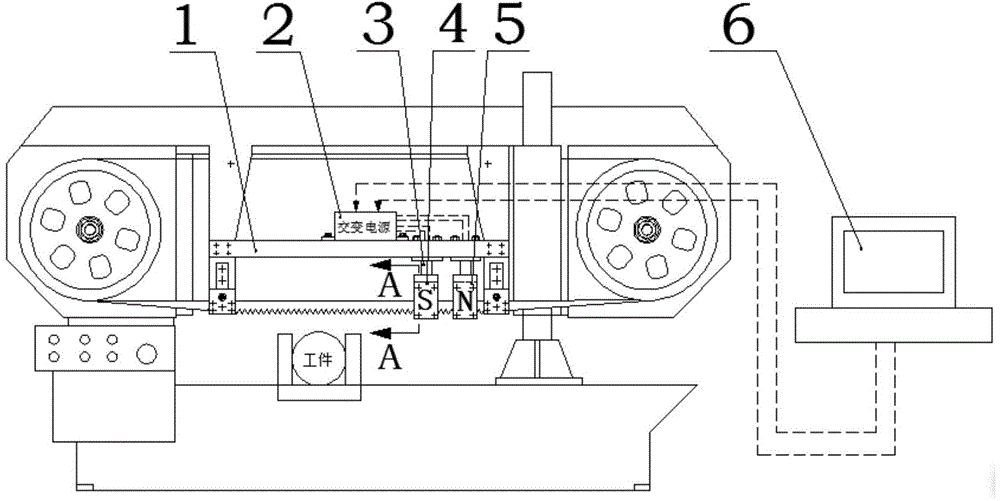

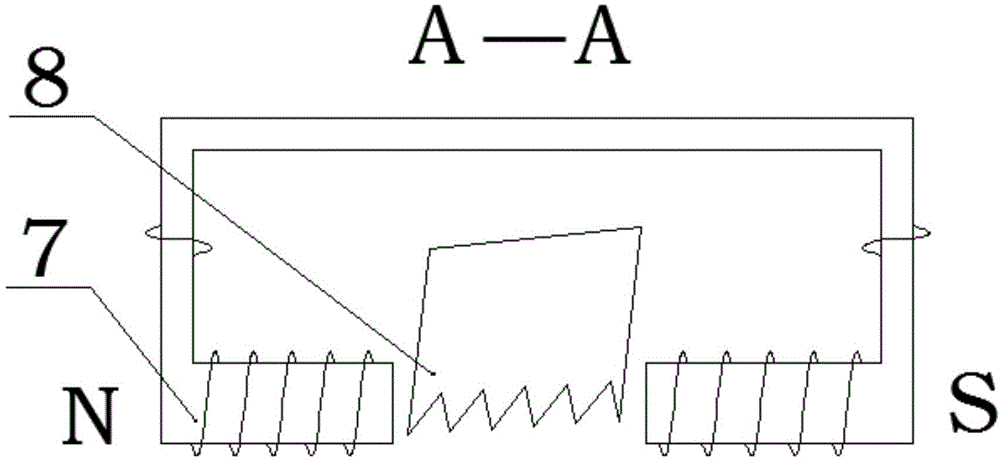

[0011] Such as figure 1 and figure 2 As shown, a sawtooth sticky pulse magnetic field removal device includes a pulse alternating power supply 2, a clamping mechanism 3, a first electromagnetic coil 4, a second electromagnetic coil 5, an industrial computer 6 and an iron core 7; the iron core 7 includes a first An iron core and a second iron core, the structures of the first iron core and the second iron core are exactly the same, the first iron core and the second iron core are rectangular structures, and an opening is opened on the bottom edge thereof, The first electromagnetic coil 4 is wound on the first iron core, the second iron core is wound around the second electromagnetic coil 5, and the winding directions of the first electromagnetic coil 4 and the second electromagnetic coil 5 are opposite;

[0012] The first iron core and the second iron core are respectively fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com