Multi-field coupling roll finishing device for conical surface

A rolling and conical surface technology, applied in the field of rolling devices, can solve problems such as unsatisfactory finishing effects, achieve good rolling surface quality, convenient and reliable use, and overcome the effect of reducing dislocation movement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

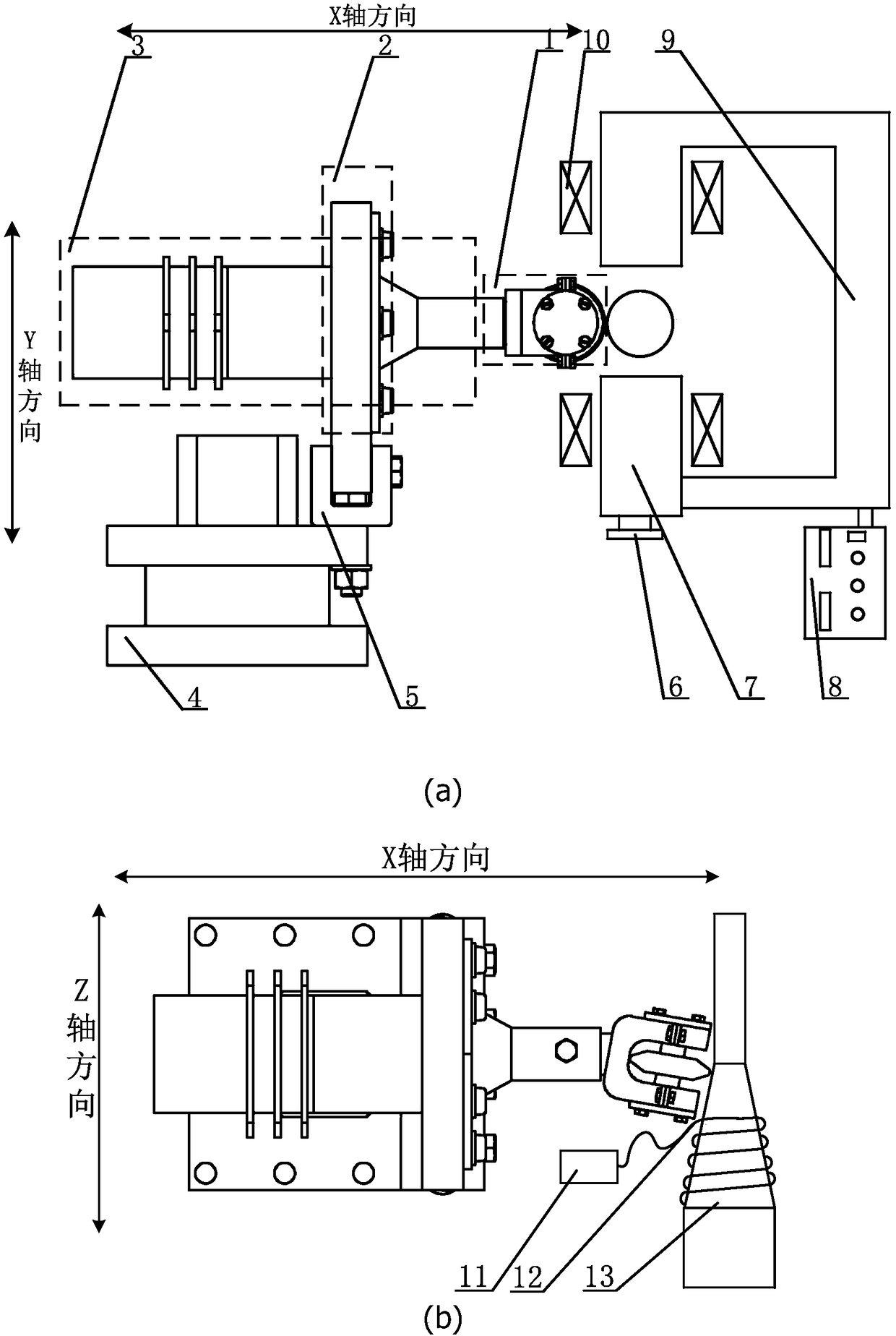

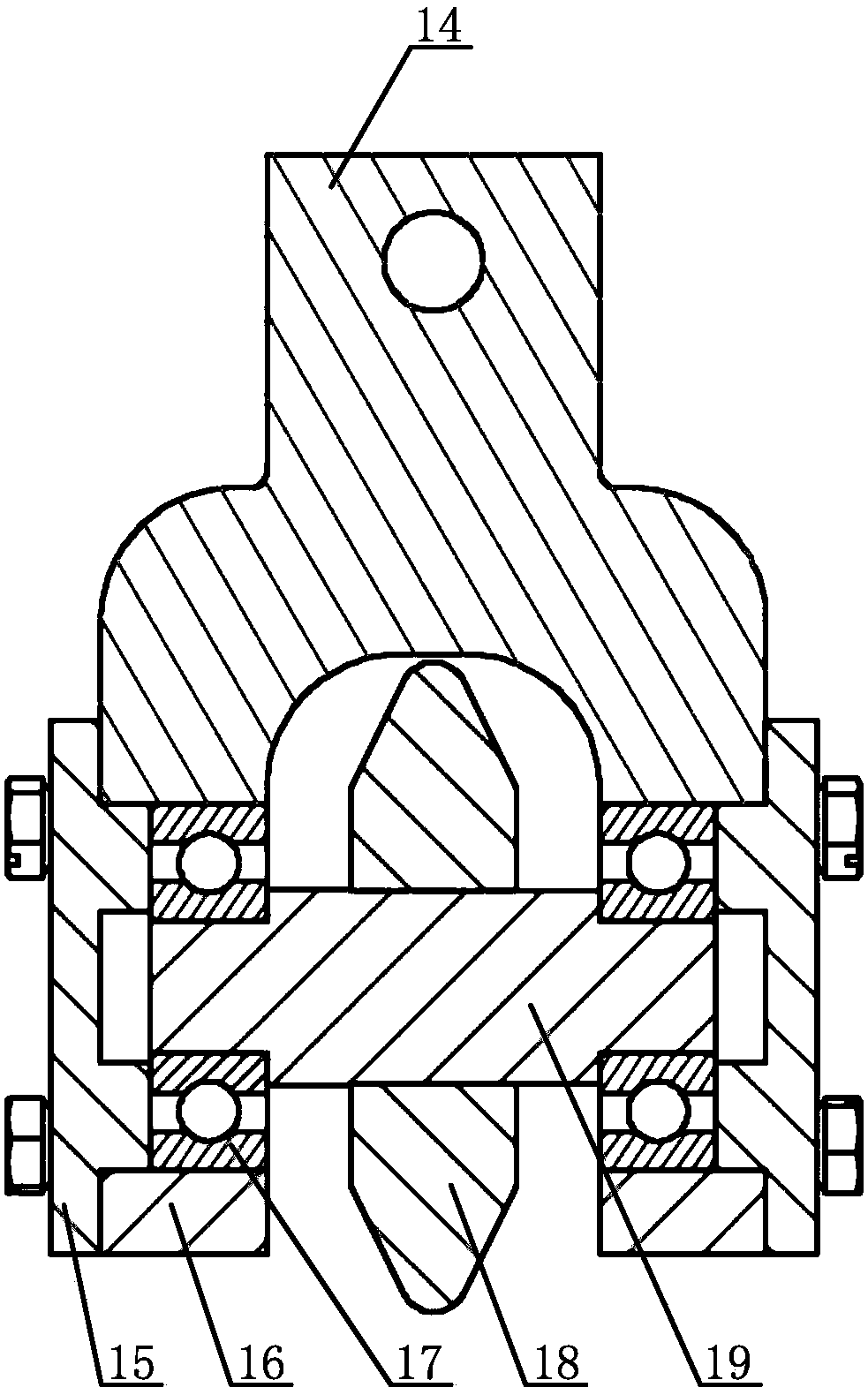

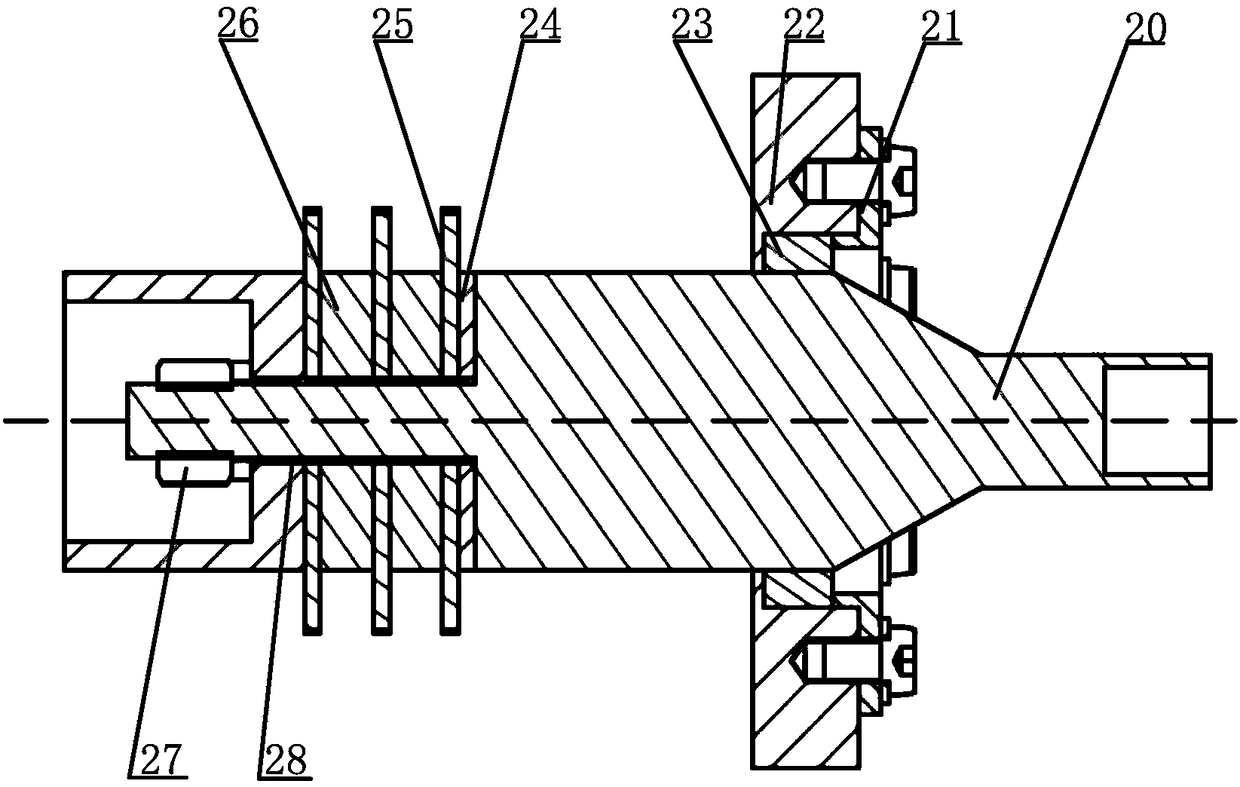

[0022] like Figure 1-4 As shown, the present invention designs a device 29 for multi-field coupling cone rolling processing that can be installed on an ordinary CNC lathe 30; the rolling knife 1 is installed on the end of the horn of the ultrasonic vibration system 3 through interference fit, The rolling knife can change different rolling angles according to different workpiece cone angles, and the ultrasonic vibration system 3 can provide ultrasonic vibration for the cone rolling; the ultrasonic vibration system 3 is installed on the dynamometer 5 through the horn support structure 2, The three-way rolling force in the rolling process can be monitored in real time through the dynamometer 5; the dynamometer 5 is fixed on the tool changer 4 of the CNC lathe 30 through bolt connection. The temperature controller 11 controls the workpiece heating temperature by controlling the current value in the thermocouple coil 10 . The frequency conversion pulse magnetic field strengthenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com