Production method of ultra-thin specification hot rolling punching steel with tensile strength of 390-510 MPa

A technology of tensile strength and production method, which is applied in the field of metallurgical plates, can solve the problems of restricting the promotion and use of steel strips for ultra-thin stamping, high production costs, and poor cold forming performance, so as to improve product profit margins and improve alloying elements. Effect of adding less and reducing deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

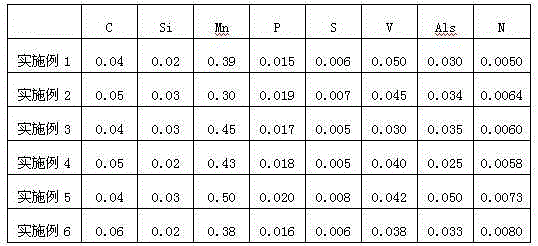

Examples

Embodiment Construction

[0025] The production method of the ultra-thin hot-rolled stamping steel strip of the present invention comprises the following steps: converter smelting→LF furnace refining→continuous casting→heating furnace heating→high-pressure water descaling before rough rolling→2-stand rough rolling→finish rolling High-pressure water descaling → 5-stand finish rolling → laminar cooling → coiling, and control the following parameters:

[0026] Continuous casting adopts liquid core pressing, the thickness of the billet is 70-75mm, the casting speed is controlled at 3.8-4.5m / min, and the tundish temperature is 1555-1565℃;

[0027] The heating of the heating furnace follows the slab heating-soaking-holding system. The furnace time is 25-35min, and the furnace temperature is 1150-1250°C to ensure that the slab is heated evenly without obvious black spots. 30°C; the temperature out of the furnace is preferably: 1180-1210°C.

[0028] High pressure water descaling pressure ≥ 28MPa before rough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com